Electromagnetic Flow Meter

Electromagnetic flow meter is a high-precision, high-reliability flow meter. It is used to measure the volume flow of conductive liquids and slurry in closed pipes, and is widely used in industries such as iron and steel, electric power, petroleum, chemical industry, coal, metallurgy, mining, paper making, water supply and drainage, food, medicine and so on.

All You Need to know About Electromagnetic Flow Meter

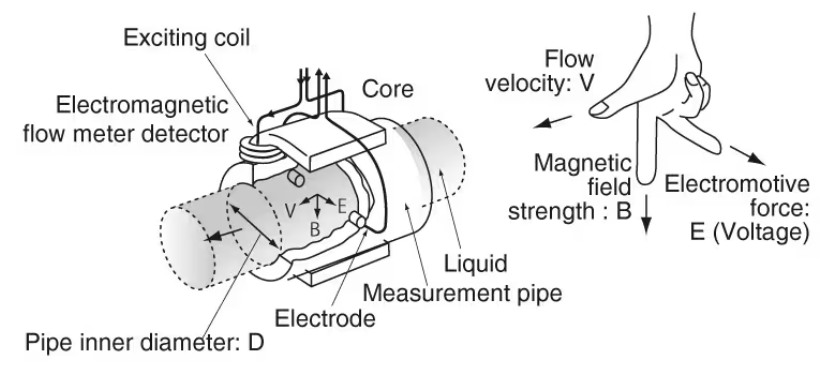

Electromagnetic Flow Meter Principle

An electromagnetic flow meter operates based on Faraday’s Law of Electromagnetic Induction, where a voltage is induced across a conductor (the flowing liquid) when it moves through a magnetic field, with the induced voltage being directly proportional to the fluid’s velocity, allowing for the measurement of flow rate by detecting this voltage between electrodes placed within the pipe; essentially, the faster the liquid flows, the higher the induced voltage is.

Advantages of Electromagnetic Flow Meter

Works with corrosive/abrasive fluids

Suitable for corrosive and abrasive fluids.

High Accuracy

Can measure flow rates with precision, especially in clean liquids and gases.

Low Maintenance

No moving parts, minimizing maintenance requirements.

Wide Application

Ability to measure both clean and dirty liquids.

How Does It Work?

An electromagnetic flow meter uses Faraday’s Law to measure flow. A magnetic field is applied perpendicular to the pipe, and as conductive fluid moves through it, a voltage is induced, detected by electrodes. This voltage is proportional to flow velocity, enabling accurate measurement. Non-intrusive and ideal for conductive liquids like water or slurries, it’s widely used in industry.

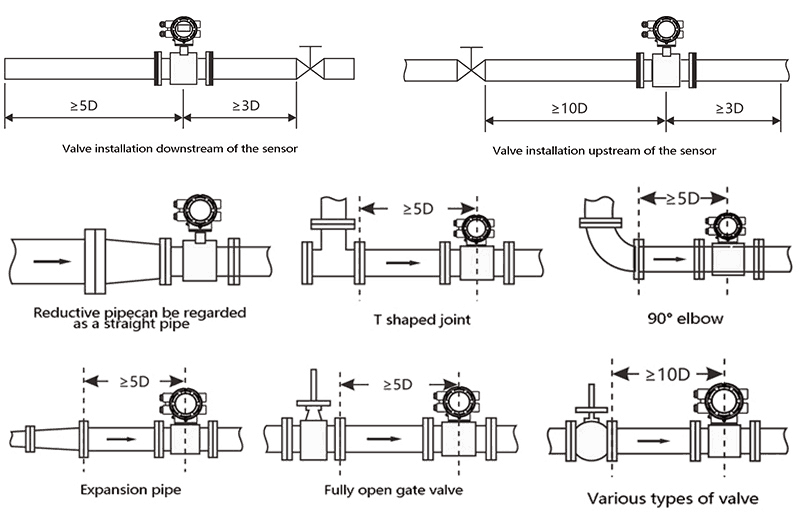

Installation Requirement

Production Process