Ever watched a sulfuric acid leak destroy a $15,000 inline flow meter—and narrowly miss injuring an operator? In our 15+ years installing flow measurement solutions across chemical plants in Shanghai and beyond, we’ve seen this nightmare scenario play out more times than we’d like to admit.

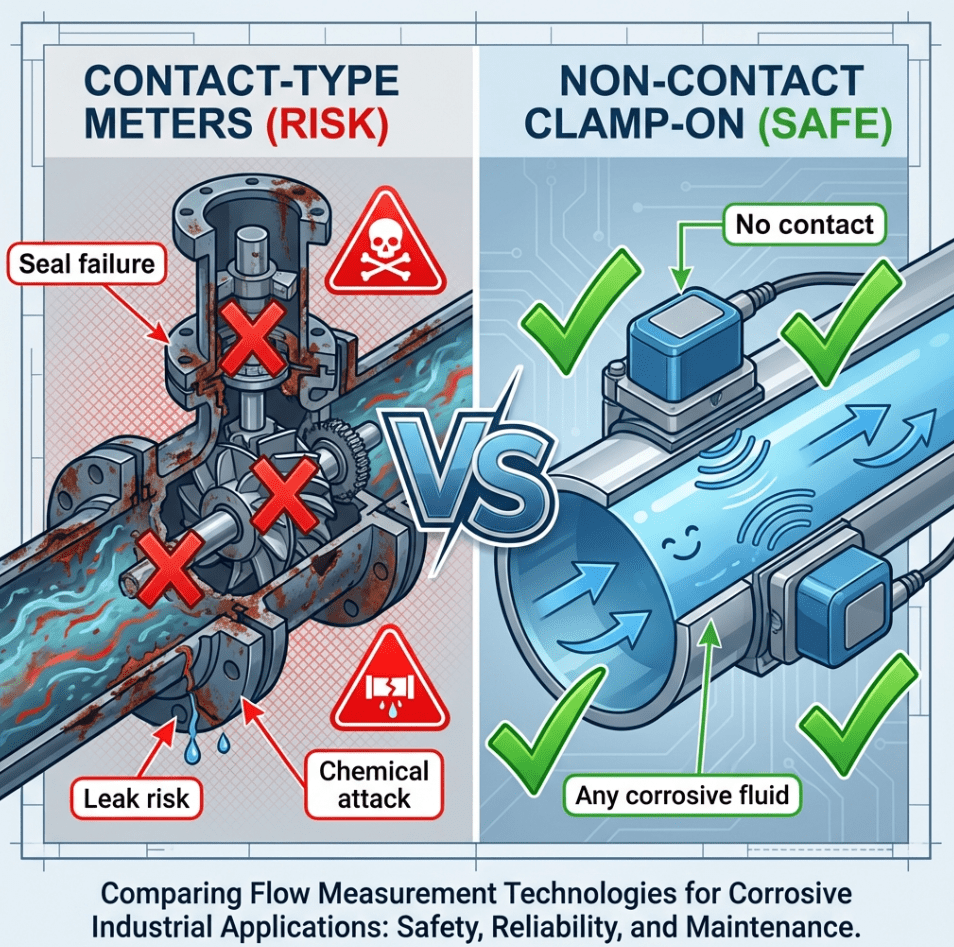

Quick Answer: For measuring corrosive liquids like acids, caustics, and aggressive chemicals, clamp-on ultrasonic flow meters are the safest choice because the transducers mount outside the pipe—never contacting the corrosive fluid. This eliminates leak risks, chemical attack on sensors, and the need for expensive exotic alloys. For conductive corrosive fluids, electromagnetic flow meters with PTFE liners are also excellent alternatives.

The chemical industry demands accurate measurement of highly aggressive media—but at what cost to safety and equipment longevity? This guide explores why non-contact flow metering technologies are revolutionizing how we handle corrosive fluids.

The Hidden Danger of Contact-Type Flow Meters in Chemical Applications

Before diving into solutions, let’s understand why traditional flow metering technologies fail in corrosive environments:

Common Failure Modes We’ve Witnessed

Based on our field experience troubleshooting failed installations:

| Meter Type | Failure Mode | Typical Lifespan in Corrosive Service |

|---|---|---|

| Turbine flow meters | Bearing corrosion, rotor seizure | 6-18 months |

| Paddle wheel meters | Paddle degradation, seal failure | 3-12 months |

| Oval gear meters | Gear erosion, seal leakage | 12-24 months |

| Variable area (rotameters) | Float corrosion, tube etching | 6-24 months |

| Positive displacement | Seal attack, rotor wear | 12-36 months |

The pattern is clear: Any meter with wetted moving parts or seals becomes a ticking time bomb in corrosive chemical service.

Real Costs Beyond Equipment Replacement

At a specialty chemical plant we consulted for in 2023, a single failure of a turbine meter on an HCl line resulted in:

- $23,000 in equipment replacement

- 14 hours of unplanned downtime

- 3 workers requiring medical evaluation (per OSHA chemical safety requirements)

- Environmental protection reporting requirements triggered

This experience fundamentally changed how we recommend flow meters for corrosive liquids. The lesson? When handling corrosive chemicals like hydrochloric acid, nitric acid, or caustic soda, the chemical resistance of your flow metering equipment isn’t optional—it’s critical for environmental protection and worker safety.

Why Clamp-On Ultrasonic Flow Meters Win for Corrosive Chemicals

The defining advantage of clamp-on ultrasonic flow meters is elegantly simple: the transducers never touch the fluid.

How Non-Contact Measurement Works

Clamp-on meters use transit-time difference technology to measure flow velocity:

- Ultrasonic transducers mount on the outside of the pipe

- Sound waves travel through the pipe wall and fluid

- The time difference between upstream and downstream signals indicates flow velocity

- Flow rate is calculated from velocity and pipe cross-section

Critical insight: Since transducers are external, the corrosive fluid never contacts any meter component. The pipe itself provides the chemical barrier. This approach enables reliable flow measurements across the widest range of aggressive fluid flow applications.

Key Advantages for Corrosive Fluids

| Advantage | Why It Matters for Chemicals |

|---|---|

| Zero leak risk | No pipe penetration = no potential leak point |

| No chemical compatibility concerns | Meter materials irrelevant to fluid chemistry |

| Easy maintenance | Remove/replace sensors without process shutdown |

| Retrofit capability | Install on existing lines without cutting pipe |

| Environmental protection | No risk of meter-induced spills |

Technical Specifications (Soaring Instrument Clamp-On Series)

Based on our company product catalog:

| Parameter | Specification |

|---|---|

| Flow Range | ±0.03 m/s to ±12 m/s |

| Accuracy | ±1% of measured value |

| Repeatability | 0.2% |

| Pipe Size | DN25-DN1200 (standard); DN15-DN40 (small pipe) |

| Pipe Material | Metal (SS, CS, Copper); Plastic (PVC, PP, PVDF) |

| Applicable Fluids | Water, Oil, Chemicals |

| Temperature Range | -40°C to +130°C (TT03 sensor) |

| Protection Class | IP65 (transmitter), IP68 (transducer) |

| Output | 4-20mA, RS485 Modbus, Pulse 0-10KHz |

Note: Specifications per company product catalog. All chemical compatibility relates to pipe material, not meter components.

Case Study: Acid Transfer Line at Semiconductor Manufacturer

Application: 48% Hydrofluoric Acid (HF) dosing line

Pipe: DN25 PVC, 15 meters total run

Previous Solution: Positive displacement meter (PVDF construction)

Problem: Seal failures every 8-12 months, $4,500 replacement cost each time

Our Solution

We installed a clamp-on ultrasonic flow meter with TT02S transducers designed for small pipes:

- Installation time: 45 minutes (no process interruption)

- Pipe modification: None required

- Chemical exposure risk: Zero

- Accuracy achieved: ±2% (standard for small pipe type; ±1% achievable after calibration per product catalog)

Results After 3 Years

| Metric | Before (PD Meter) | After (Clamp-On) |

|---|---|---|

| Annual maintenance cost | $4,500+ | $0 |

| Unplanned downtime | 16 hours/year | 0 hours |

| Safety incidents | 2 near-misses | 0 |

| Leak events | 1 minor | 0 |

Lesson learned: For the most aggressive corrosive chemicals, the safest meter is one that never touches the fluid.

Alternative Technologies for Corrosive Fluids

While clamp-on ultrasonic is our top recommendation, other technologies have their place:

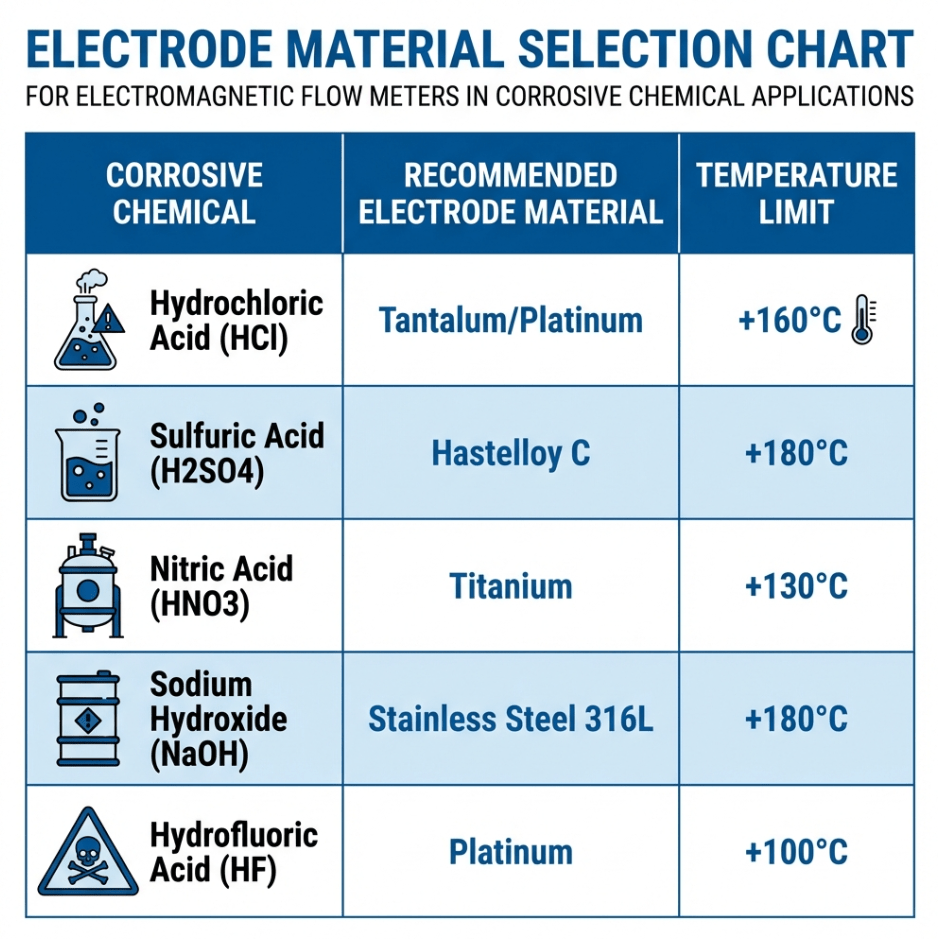

Electromagnetic Flow Meters (For Conductive Corrosives)

Electromagnetic flow meters work excellently for conductive corrosive fluids when properly specified:

Key requirements:

- Fluid conductivity ≥20 µS/cm

- PTFE or PFA liner for chemical resistance

- Hastelloy, Titanium, or Tantalum electrodes

Soaring Instrument EMF specifications for corrosive service (per company product catalog):

- Lining: PTFE, F46, PFA (verified compatible with most corrosive chemicals per Engineering ToolBox corrosion data

- Electrodes: SUS316, Hastelloy B, Hastelloy C, Titanium, Tantalum, Stainless Steel Coated Tungsten Carbide

- Accuracy: ±0.5% (±0.2% optional)

- Working Pressure: Up to 42 MPa (for high pressure type)

- Temperature: Medium temp: -40°C to +180°C (standard type); -10°C to +160°C (high pressure type)

- Conductivity Requirement: ≥20 µS/cm

When to choose EMF over clamp-on:

- High accuracy required (±0.5% vs ±1%)

- Conductive fluid confirmed

- New installation (easier inline integration)

- Need precise flow rates for billing/custody transfer

When NOT to Use Ultrasonic for Corrosive Fluids

Limitations to understand:

- High solids content (>5%) – Transit-time meters struggle with particles; consider Doppler technology or EMF

- Aerated fluids – Gas bubbles disrupt ultrasonic signal

- Non-homogeneous mixtures – Variable acoustic properties affect accuracy

- Very low flow velocities (<0.1 m/s) – Signal resolution limits

For abrasive slurries with corrosive properties, electromagnetic flow meters may be more suitable.

Flow Meter Selection Decision Tree for Corrosive Liquids

Use this decision framework based on our field experience:

START: Is the fluid corrosive?

│

├── YES → Is it conductive (>20 µS/cm)?

│ │

│ ├── YES → Does it contain solids/particles?

│ │ │

│ │ ├── YES → EMF with PTFE liner + Hastelloy electrodes

│ │ │

│ │ └── NO → EMF OR Clamp-on (choose based on accuracy needs)

│ │

│ └── NO → Clamp-on ultrasonic (transducers outside pipe)

│

└── NO → Standard flow meter technologies applicableInstallation Best Practices for Chemical Service

Clamp-On Ultrasonic Installation Tips

From our installations at 50+ chemical facilities:

Pipe condition matters

- Surface should be clean, free of rust/scale

- Use coupling gel designed for the temperature range

Transducer placement

- Horizontal pipes: Mount at 3 or 9 o’clock position

- Avoid top (gas accumulation) and bottom (sediment)

Pipe material entry

- Verify pipe material in meter setup (PVC, PP, PVDF, SS, etc.)

- Enter correct wall thickness

Electromagnetic Flow Meter Installation for Corrosives

Grounding is critical

- Ensure proper grounding to prevent electrode issues

Liner selection

- PTFE: General corrosive service, -40°C to +180°C

- PFA: Higher purity applications

Electrode material matching (selection based on corrosion resistance data):

- HCl (hydrochloric acid): Tantalum or Platinum

- H₂SO₄ (sulfuric acid): Hastelloy C

- NaOH (caustic soda): Stainless steel 316L

- HNO₃ (nitric acid): Titanium

Troubleshooting Common Issues

Clamp-On Ultrasonic Problems in Chemical Service

| Symptom | Likely Cause | Solution |

|---|---|---|

| No signal | Pipe coating/scale buildup | Clean pipe surface, reapply coupling |

| Erratic readings | Air bubbles in fluid | Move sensor away from pumps/valves |

| Accuracy drift | Temperature changes | Enable temperature compensation |

| Signal loss at high temp | Coupling gel degradation | Use high-temperature gel |

Electromagnetic Flow Meter Issues

| Symptom | Likely Cause | Solution |

|---|---|---|

| Zero output | Electrode coating | Clean electrodes per manufacturer guidelines |

| Unstable reading | Poor grounding | Install grounding rings |

| Liner damage | Chemical incompatibility | Verify material vs. chemical |

Comparative Cost Analysis

5-Year Total Cost of Ownership

Based on our project data for a DN50 corrosive acid line:

| Cost Factor | Turbine Meter | Clamp-On Ultrasonic | EMF (PTFE/Hastelloy) |

|---|---|---|---|

| Initial cost | $800 | $2,500 | $3,500 |

| Installation | $500 (cut pipe) | $200 (no cutting) | $600 (cut pipe) |

| Replacements (5 yr) | $2,400 (3x) | $0 | $0 |

| Maintenance | $1,500 | $100 | $300 |

| Downtime cost | $4,000 | $0 | $500 |

| TOTAL 5-YEAR | $9,200 | $2,800 | $4,900 |

The "cheap" option costs 3x more over 5 years.

Frequently Asked Questions

1. Can clamp-on meters work on plastic pipes carrying acids?

Yes. Our clamp-on ultrasonic meters are compatible with PVC, PP, and PVDF pipes commonly used for corrosive chemicals. For small pipes (DN15-DN40), use TT02S transducers (0°C to +65°C) or TT03S (0°C to +115°C). Note the temperature starts at 0°C for small pipe sensors, not -40°C like the large pipe versions.

2. What accuracy can I expect with clamp-on meters on corrosive fluids?

Typical accuracy is ±1% of measured value after proper setup (clamp-on type), or ±2% for small pipe type (±1% after calibration). This is sufficient for most chemical process control applications. For custody transfer requiring ±0.5% or better, consider electromagnetic flow meters.

3. How do I know if my corrosive fluid is conductive enough for an EMF?

Most water-based acids and alkalis are conductive. Required minimum conductivity is ≥20 µS/cm (per product catalog). Pure solvents, hydrocarbons, and deionized water are typically non-conductive and require ultrasonic measurement.

4. What temperature limits apply to clamp-on meters for chemical service?

Our transducer options cover a wide range:

- TT01/TT02: -40°C to +80°C (standard)

- TT03: -40°C to +130°C (high temperature)

- TT02H: -40°C to +180°C (extreme high temperature)

5. Are there any corrosive fluids that cannot be measured with ultrasonic?

Ultrasonic meters struggle with:

- Highly aerated fluids (>2% gas content)

- Heavy slurries (>30-40% solids)

- Non-homogeneous mixtures with varying acoustic properties

For these applications, consider specialized EMF configurations.

6. How often should I recalibrate flow meters in corrosive service?

Clamp-on ultrasonic meters typically need recalibration every 2-3 years under stable conditions. EMF meters may require more frequent verification if electrode coating occurs.

7. What’s the difference between transit-time and Doppler ultrasonic for chemicals?

Transit-time is preferred for clean, homogeneous corrosive fluids (most chemical applications). Doppler works with fluids containing particles or bubbles—but most corrosive chemical processes use clean fluids where transit-time excels.

Key Takeaways

- ✅ Non-contact clamp-on ultrasonic is the safest flow meter for corrosive liquids—zero leak risk

- ✅ Electromagnetic flow meters with PTFE liners and exotic electrodes work excellently for conductive corrosive fluids

- ✅ Avoid contact-type meters (turbine, paddle wheel, oval gear) in aggressive chemical service

- ✅ True cost includes replacements, downtime, and safety—not just purchase price

- ✅ Clamp-on installation takes minutes, requires no process shutdown, and eliminates chemical exposure risk

Choose the Right Flow Meter for Your Corrosive Application

At Soaring Instrument, we’ve helped chemical plants, semiconductor fabs, and water treatment facilities across Asia find the right flow measurement solutions for their most challenging corrosive fluids. Our meter offers reliable, long-term fluid flow monitoring without the risks of contact-type instruments.

Our Product Range for Corrosive Service:

- Clamp-On Ultrasonic Flow Meters (DN25-DN1200 standard; DN15-DN40 small pipe) – Zero contact with fluid

- Electromagnetic Flow Meters (DN3-DN3000) – PTFE/PFA lined, exotic electrodes

- Portable Ultrasonic Meters – Temporary verification without installation

Need help selecting the right meter for your corrosive fluid application?

📧 Email: [email protected]

📞 Phone: +86-21-57652429

💬 WhatsApp: +86-13585991410

Contact our engineering team →

Related Articles

- What Flow Meter Should You Choose for Corrosive Liquids?

- Can Electromagnetic Flow Meters Handle Corrosive or Abrasive Fluids?

- The Complete Guide Of Ultrasonic Flow Meter

- Electrode Materials Face-Off: Titanium vs. Hastelloy vs. Platinum

- What Is the Difference Between Electromagnetic and Ultrasonic Flow Meters

Last Updated: February 2026

Author: Soaring Instrument Technical Team