Nearly 35% of uncalibrated vortex meters develop measurement errors exceeding 2% within 12 months. Proper calibration maintains accuracy for custody transfer and process control applications.

Vortex flow meter calibration involves comparing meter output against a master flow standard, adjusting the K-factor (pulses per unit volume), and verifying linearity across 5-7 flow rates. Factory calibration typically achieves ±0.5-1.0% accuracy, while field calibration using portable provers reaches ±1-2% precision.

Calibration Rig Diagram

Calibration directly impacts measurement reliability and compliance. The following sections detail calibration procedures and accuracy considerations.

How to Calibrate a Vortex Meter?

Three calibration methods compared:

Calibration Approach Matrix

| Method | Accuracy | Equipment Needed | Typical Cost | Time Required |

|---|---|---|---|---|

| Wet calibration | ±0.25% | Master meter, test loop | $$$$ | 1-2 days |

| Dry calibration | ±0.75% | Signal generator, HART | $$ | 2-4 hours |

| Field verification | ±1.5% | Portable prover | $$$ | 4-8 hours |

Step-by-Step Wet Calibration:

Setup Preparation

- Mount meter in test rig

- Stabilize fluid temperature

- Verify pipe full condition

- Zero pressure transmitters

Flow Testing

- Run 5-7 flow rates (10-100% Qmax)

- Record pulses and reference volume

- Calculate K-factor at each point

- Check linearity (<0.5% deviation)

Final Adjustment

- Program average K-factor

- Verify zero flow cutoff

- Test at 25/50/75% points

- Seal calibration access

%(percentage)calibration process

K-Factor Determination

Dry Calibration Shortcut:

Signal Simulation

- Apply known frequencies

- 100Hz = typical full scale

- 25/50/75Hz check points

- Verify output scaling

Parameter Verification

- Pipe diameter setting

- Fluid density value

- Temperature coefficients

- Damping factors

Diagnostic Tests

- Piezo sensitivity

- Circuit response time

- Noise rejection

Calibration Check Acceptable Range Corrective Action K-factor repeatability ±0.2% Re-test flow points Zero offset <0.1% FS Re-zero sensor Linearity error <0.5% Adjust curve fit Temperature drift <0.05%/°C Update compensation

How Do You Calibrate Flow Meters?

Flow Standard Selection Guide:

Reference Standard Options

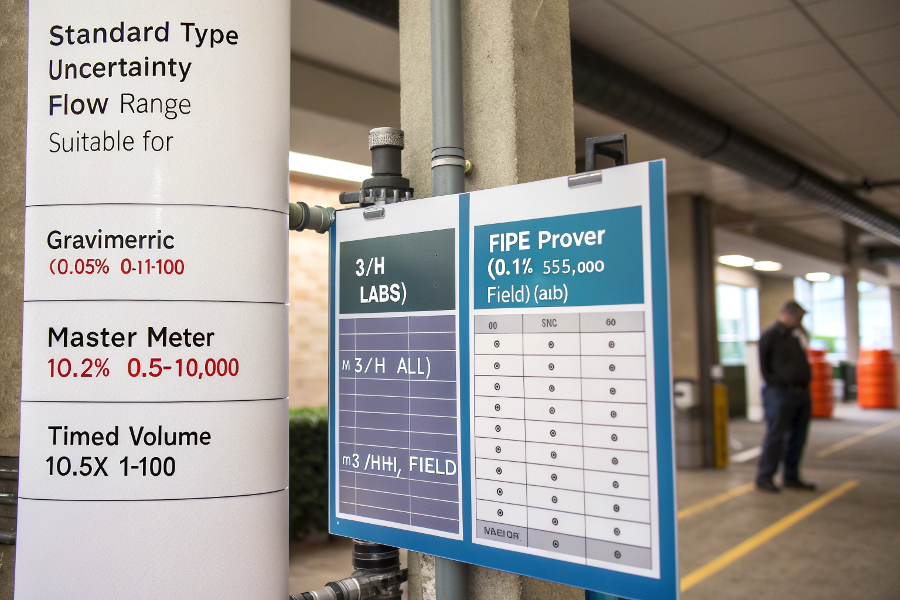

| Standard Type | Uncertainty | Flow Range | Suitable For |

|---|---|---|---|

| Gravimetric | ±0.05% | 0.1-100 m³/h | Labs |

| Pipe prover | ±0.1% | 5-5,000 m³/h | Field/Lab |

| Master meter | ±0.2% | 0.5-10,000 m³/h | All |

| Timed volume | ±0.5% | 1-100 m³/h | Field |

Calibration Best Practices:

Pre-Calibration Checks

- Verify reference standard certification

- Confirm fluid properties match

- Check for air bubbles

- Stabilize system temperature

Test Execution

- Minimum 5 test points

- 30-second minimum per point

- 3 repetitions per flow rate

- Reverse flow check (if applicable)

Post-Calibration Steps

- Apply security seals

- Document all adjustments

- Print calibration certificate

- Note ambient conditions

Multi-Standard Comparison

Flow Calibration Equations:

K-factor Calculation:

K = (Pulses counted) / (Reference volume)Accuracy Determination:

Error % = 100 × (Meter – Reference)/ReferenceUncertainty Budget:

Total = √(Std² + Temp² + Press² + Time²)

| Standard Type | Vortex | Turbine | Ultrasonic | Coriolis |

|---|---|---|---|---|

| Gravimetric | ✓ | ✓ | ✓ | ✓ |

| Pipe prover | ✓ | ✓ | ✓ | ✗ |

| Master meter | ✓ | ✓ | ✓ | ✓ |

| Timed volume | Limited | Limited | ✗ | ✗ |

How Do You Troubleshoot a Vortex Flow Meter?

Calibration-Related Faults:

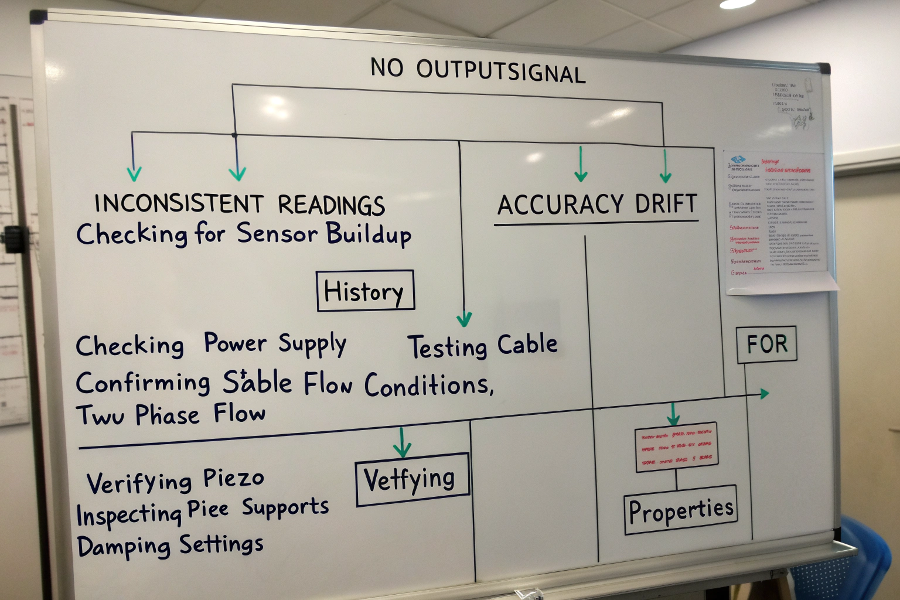

Troubleshooting Flowchart

No Output Signal

- Check power supply (24V DC)

- Test cable continuity

- Verify piezo voltage (>1mV)

- Inspect for complete blockages

Inconsistent Readings

- Confirm stable flow conditions

- Check for two-phase flow

- Verify proper grounding

- Test damping settings

Accuracy Drift

- Review calibration history

- Check for sensor buildup

- Verify fluid properties

- Inspect pipe supports

%(percentage)troubleshooting path

Diagnostic Decision Tree

Calibration Stability Indicators:

Normal Performance:

- <1% annual K-factor change

- Consistent zero offset

- Repeatable linearity

Warning Signs:

2% seasonal variation

- Shifting zero point

- Changing temperature response

Symptom Possible Cause Calibration Impact High noise Cavitation ±5-15% error Signal dropout Damaged piezo Complete failure Step changes Loose parts ±2-10% shifts Gradual drift Coating buildup 1-3%/year

How Accurate Is the Vortex Flow Meter?

Accuracy Class Breakdown:

Vortex Meter Performance Data

| Condition | Typical Accuracy | Influencing Factors | Improvement Methods |

|---|---|---|---|

| Lab calibrated | ±0.5% of rate | Reference standard | NIST-traceable cal |

| Field installed | ±1-1.5% | Installation effects | Flow conditioners |

| Dirty service | ±2-3% | Coating buildup | Frequent cleaning |

| Low flow (<10%) | ±5% | Signal-to-noise | Higher range meter |

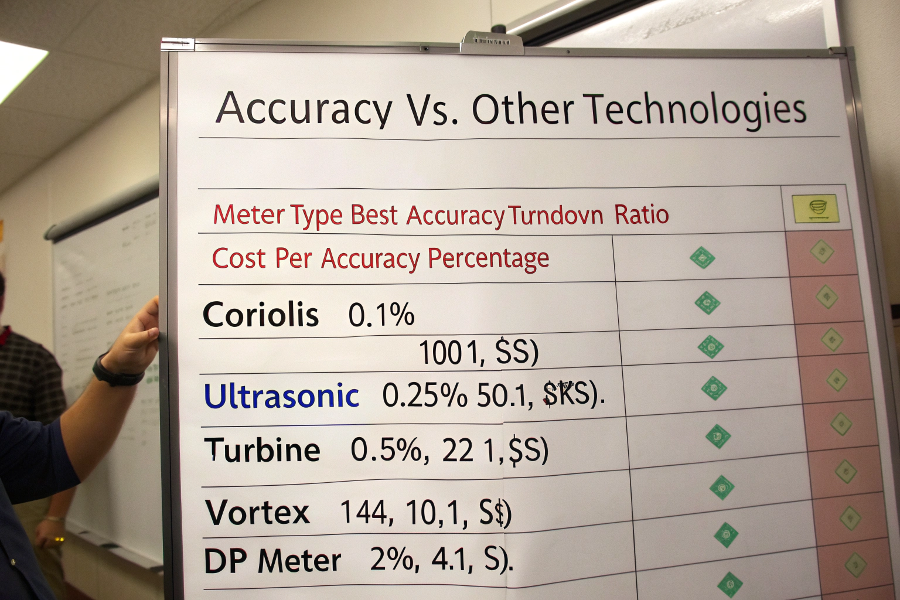

Accuracy vs. Other Technologies:

| Meter Type | Best Accuracy | Turndown Ratio | Cost per Accuracy % |

|---|---|---|---|

| Coriolis | ±0.1% | 100:1 | $$$$ |

| Ultrasonic | ±0.25% | 50:1 | $$$ |

| Turbine | ±0.5% | 20:1 | $$ |

| Vortex | ±1% | 10:1 | $ |

| DP meter | ±2% | 4:1 | $ |

%(percentage)accuracy comparison

Technology Benchmark

Maintaining Accuracy:

Annual Verification

- Zero check

- Span verification

- K-factor stability

- Temperature test

Process Monitoring

- Daily comparison checks

- Monthly trend analysis

Flow Range Expected Accuracy Typical Industry Use 100-90% ±1% Custody transfer 90-30% ±1.5% Process control 30-10% ±3% Monitoring only <10% Not recommended –

Conclusion

Proper vortex flow meter calibration establishes traceable measurement accuracy between ±0.5-2% depending on method and conditions. Regular recalibration (annually for critical applications, biennially for others) combined with routine verification checks maintains optimal performance. While vortex meters can’t match Coriolis-grade precision, their 1% typical accuracy at 10:1 turndown provides reliable measurement for most industrial processes at significantly lower cost than higher-accuracy alternatives.