Your mag meter suddenly shows erratic readings – did you check the grounding? Poor grounding causes 50% of all mag meter failures in the field.

Magnetic flow meters require grounding to complete the electrical circuit for accurate measurement. Without proper grounding: 1) Stray voltages distort the weak flow signal (typically 1-10mV), 2) Electrical noise interferes with measurements, 3) Safety hazards from static buildup occur, especially in flammable fluids.

Let’s examine why grounding is non-negotiable for mag meter operation.

Why Is Grounding Important in a Magnetic Flow Meter?

The physics of mag meters demands a closed electrical loop.

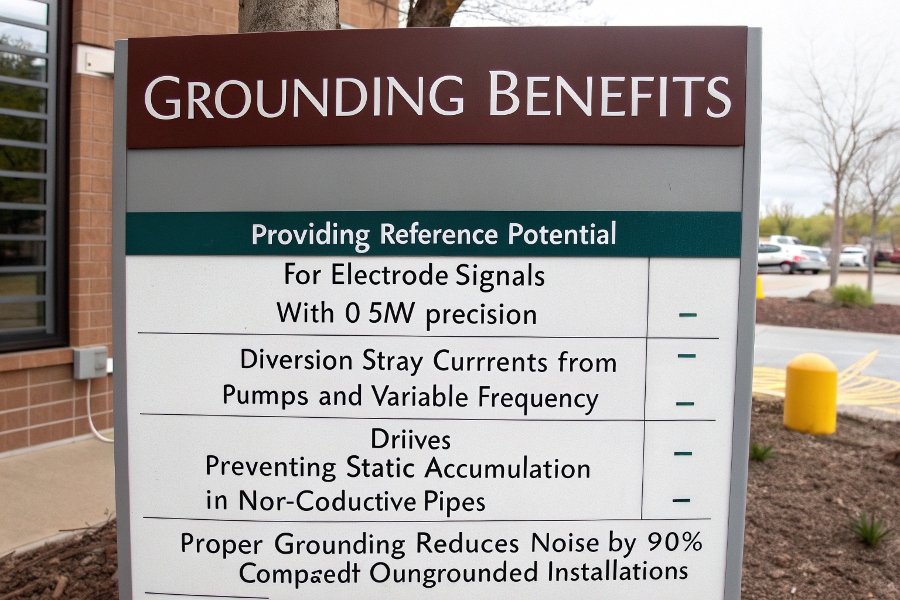

Grounding serves three critical functions: 1) Provides reference potential for the electrode signals (0.5mV precision needed), 2) Diverts stray currents from pumps/variable frequency drives, 3) Prevents static accumulation in non-conductive pipes. Proper grounding reduces noise by 90%1 compared to ungrounded installations.

Grounded vs Ungrounded Performance

Grounding quality directly impacts accuracy:

Grounding Resistance vs Measurement Error

| Ground Resistance | Signal Noise | Typical Error | Solution |

|---|---|---|---|

| <1 ohm | 0.1% FS | ±0.5% | Ideal |

| 1-5 ohms | 0.5% FS | ±1.5% | Acceptable |

| 5-10 ohms | 2% FS | ±5% | Needs improvement |

| >10 ohms | 10% FS | Unreliable | Immediate fix required |

What Are Grounding Rings For Magnetic Flow Meters?

These unassuming metal rings solve conductivity challenges.

Grounding rings (also called earth rings) create electrical contact points when: 1) Pipe material is non-conductive (PVC, lined steel), 2) Fluid conductivity is marginal (>5μS/cm but <50μS/cm), 3) Electrodes cannot reliably contact the fluid. They’re always required for lined pipes and low-conductivity liquids (<20μS/cm).

Grounding Ring Cross-Section

Grounding ring selection guidelines:

Grounding Ring Types and Applications

| Type | Material | Best For | Limitations |

|---|---|---|---|

| Standard | 316SS | Water, chemicals | Not for acids |

| Hastelloy | C276 | Corrosive fluids | High cost |

| Flanged | Carbon steel | Large pipes | Needs coating |

| Insertion | Titanium | High-purity systems | Limited sizes |

| Capacitive | Ceramic-coated | Abrasive slurries | Reduced sensitivity |

What Are the Requirements for a Magnetic Flow Meter?

Five installation must-haves for reliable operation.

Essential requirements: 1) Proper grounding system (<1 ohm preferably), 2) Full pipe conditions (no air/gas pockets), 3) Minimum conductivity (5μS/cm standard, 20μS/cm for low-flow), 4) Pipe vibration isolation, 5) Adequate straight runs (5D upstream, 3D downstream minimum). Missing any single requirement can cause 10-100% measurement errors.

Mag Meter Pre-Commissioning Checks</50μS/cm)

Verification procedure table:

Magnetic Flow Meter Installation Verification

| Checkpoint | Tool/Method | Pass Criteria |

|---|---|---|

| Ground continuity | Multimeter (Ω mode) | <1 ohm pipe to ground |

| Pipe fill | Ultrasonic tester | Continuous liquid sound |

| Conductivity | Lab analyzer | >5μS/cm for water |

| Installation angle | Digital level | Avoid top-mounted if possible |

| Electrical isolation | Megohmmeter | >20MΩ between phases |

What Are the Disadvantages of Magnetic Flow Meter?

Every technology has limitations – here’s when to avoid mag meters.

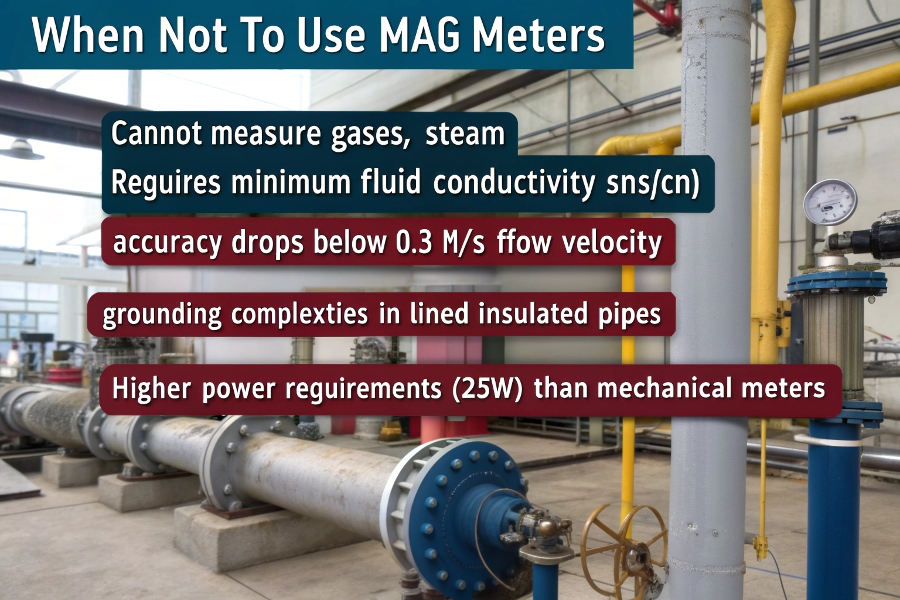

Key limitations: 1) Cannot measure gases/steam (no conductivity), 2) Requires minimum fluid conductivity (5μS/cm), 3) Accuracy drops below 0.3 m/s flow velocity, 4) Grounding complexities in lined/insulated pipes, 5) Higher power requirements (25W) than mechanical meters. These constraints make them unsuitable for 30% of industrial flow applications.

When Not to Use Mag Meters

Comparison with alternative technologies:

Flow Meter Technology Selection Guide

| Application | Mag Meter Suitable? | Better Alternatives |

|---|---|---|

| Distilled water | No (low conductivity) | Coriolis, ultrasonic |

| LPG transfer | No (non-conductive) | Turbine, positive displacement |

| High-viscosity oil | Marginal | Coriolis, oval gear |

| Slurries >20% solids | Yes (with ceramic liner) | – |

| Steam lines | Never | Vortex, differential pressure |

Cost Analysis: Grounding System Components

Proper grounding requires specific investment.

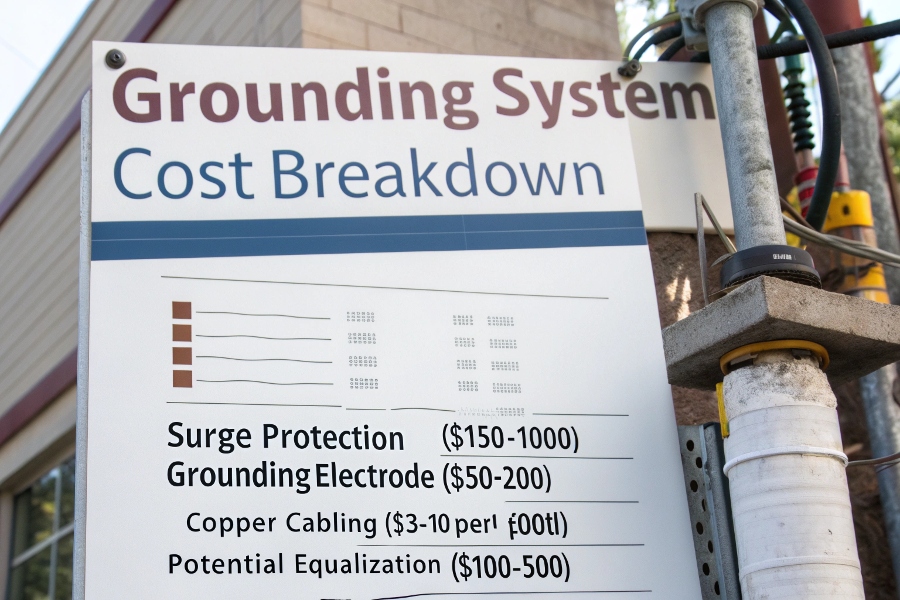

Typical grounding system costs: 1) Grounding electrode ($50-200), 2) Copper cabling ($3-10/ft), 3) Potential equalization ($100-500), 4) Surge protection ($150-1000). While adding 5-15% to project costs, proper grounding prevents 80% of mag meter failures (saving $2000+ per service call).

Grounding System Cost Breakdown

Component selection matrix:

Grounding System Component Options

| Component | Budget Option | Premium Choice | OEM Solution |

|---|---|---|---|

| Ground rod | Galvanized steel | Copper-bonded rod | Integrated flange ground |

| Cable | 6 AWG copper | 4 AWG tinned copper | Double-shielded coax |

| Clamps | Standard brass | Exothermic weld | Certified explosion-proof |

| Protection | Basic lightning arrester | Zone 0 intrinsically safe | Fiber-optic isolated |

Conclusion

Magnetic flow meters require proper grounding to complete the measurement circuit, eliminate noise, and ensure safety. While grounding adds complexity and cost, it’s essential for achieving the technology’s promised ±0.5% accuracy. Non-conductive pipes and low-conductivity fluids demand special grounding solutions like grounding rings. When proper installation requirements cannot be met, alternative flow measurement technologies should be considered.

This information is vital for optimizing mag meter performance and ensuring precise readings in your systems. ↩