Precision measurement matters in industries where a 1% error can cost $100,000 annually. Turbine meters solve this problem for specific fluid types.

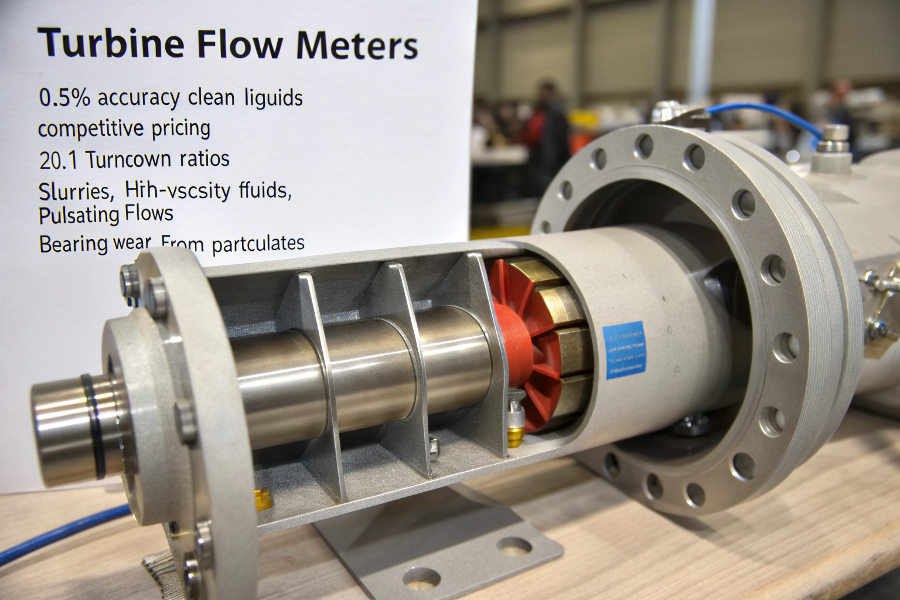

The primary advantage of turbine flow meters is their ±0.5% accuracy with clean liquids (viscosity <10 cSt) at competitive prices, while their major disadvantage is bearing wear from particulates (50-200ppm max). They offer 20:1 turndown ratios, fast 100ms response times, and direct pulse output – but fail with slurries, high-viscosity fluids, or pulsating flows.

Turbine Meter Mechanics

To make informed decisions, engineers must weigh these factors carefully. Here’s a detailed breakdown.

What Are the Advantages of Turbine Flow Meter?

Six Technical Superiorities:

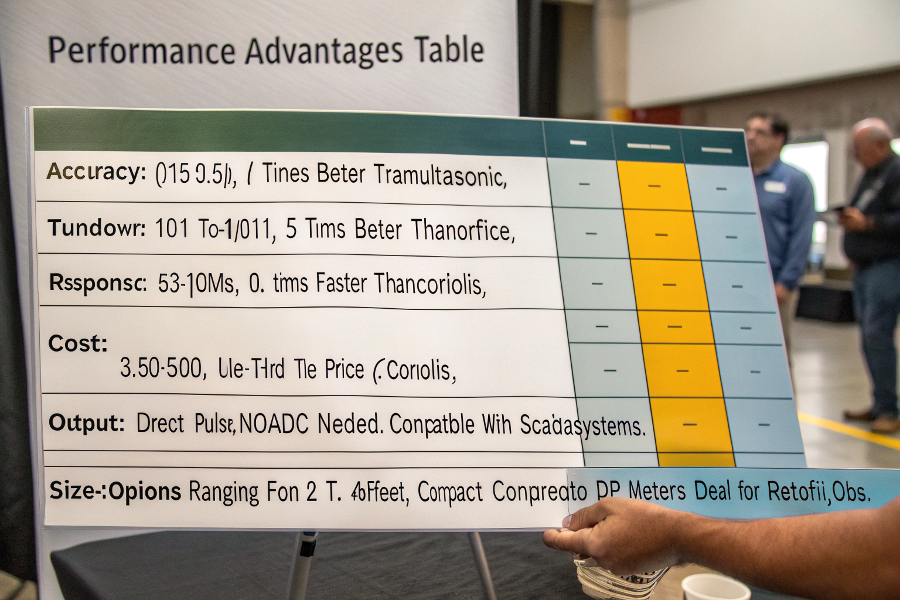

Performance Advantages Table

| Advantage | Metric | Comparison | Industry Impact |

|---|---|---|---|

| Accuracy | ±0.15-0.5% | 2x better than ultrasonic | Custody transfer |

| Turndown | 10:1 to 100:1 | 5x better than orifice | Variable flows |

| Response | 50-100ms | 10x faster than Coriolis | Process control |

| Cost | $1,500-$5,000 | 1/3 price of Coriolis | Budget projects |

| Output | Direct pulse | No ADC needed | SCADA systems |

| Size | 2-48" options | Compact vs PD meters | Retrofit jobs |

Mechanical Benefits:

Simple Design

- Rotor + pickup only

- No pressure taps

- Minimal electronics

Proven Technology

- 60+ years refinement

- API/ASTM standards

- Extensive case history

Flexible Installations

- Any orientation

- Short lay length

Model Type Accuracy Flow Range Price Range Standard ±0.5% 0.3-10 ft/s $2k-$15k Custody ±0.15% 1-50 ft/s $8k-$50k Sanitary ±0.25% 0.5-25 ft/s $5k-$30k

Technology Benchmark

Economic Advantages:

- Low TCO: 5-10 year lifespan

- Easy Calibration: Field check possible

- Interchangeable: Standard fittings

What Are the Advantages and Disadvantages of Flow Meters?

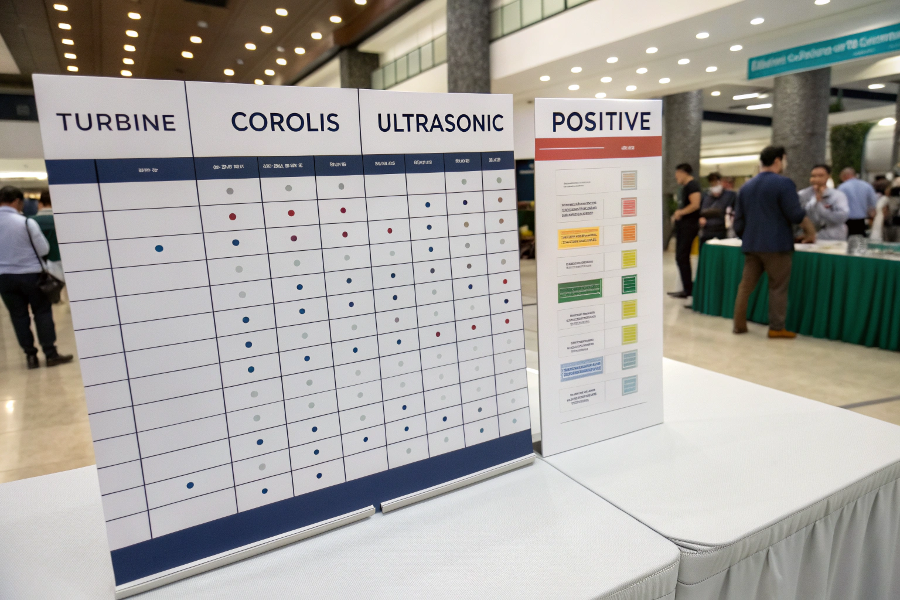

Technology Cross-Comparison:

Flow Meter Tradeoff Matrix

| Type | Pros | Cons | Best Case |

|---|---|---|---|

| Turbine | Price, accuracy | Wear, clean fluids | Mid-range hydrocarbons |

| Coriolis | All fluids, mass flow | Cost, size | High-value chemicals |

| Ultrasonic | No pressure drop | Accuracy, price | Large water pipes |

| Positive | Viscous fluids | Maintenance | Fuel oil, syrups |

Turbine Positioning:

Sweet Spot

- Clean liquids

- ½"-12" pipes

- $100k-$5M systems

When to Avoid

- Abrasives present

- Viscosity >25cSt

- Pulsation >10%

Emerging Threats

- Coriolis cost reduction

- Ultrasonic improvements

Application Mapping

Decision Factors:

- Capital Cost: 15-25% project budget

- Operating Cost: $500-$5k/year

- Failure Risk: 2-5% annual probability

What Are the Disadvantages of Turbine Meter?

Five Critical Limitations:

Failure Mode Analysis

| Limitation | Effect | Mitigation | Cost Impact |

|---|---|---|---|

| Bearing wear | Accuracy drift | Annual checks | $1k-$5k/yr |

| Particulates | Jamming | 100µ filters | $500-$2k |

| Viscosity | Nonlinearity | Avoid >10cSt | 1-5% error |

| Pulsation | RPM error | Dampeners | $2k-$10k |

| Installation | Swirl | Flow conditioners | $1k-$5k |

Maintenance Challenges:

Bearing Replacement

- Every 2-5 years

- Requires recalibration

- 4-8 hour downtime

Filter Clogging

- Monthly inspections

- Differential pressure rise

- Production interruptions

Calibration Shift

- ±0.1%/year typical

- Prover truck needed

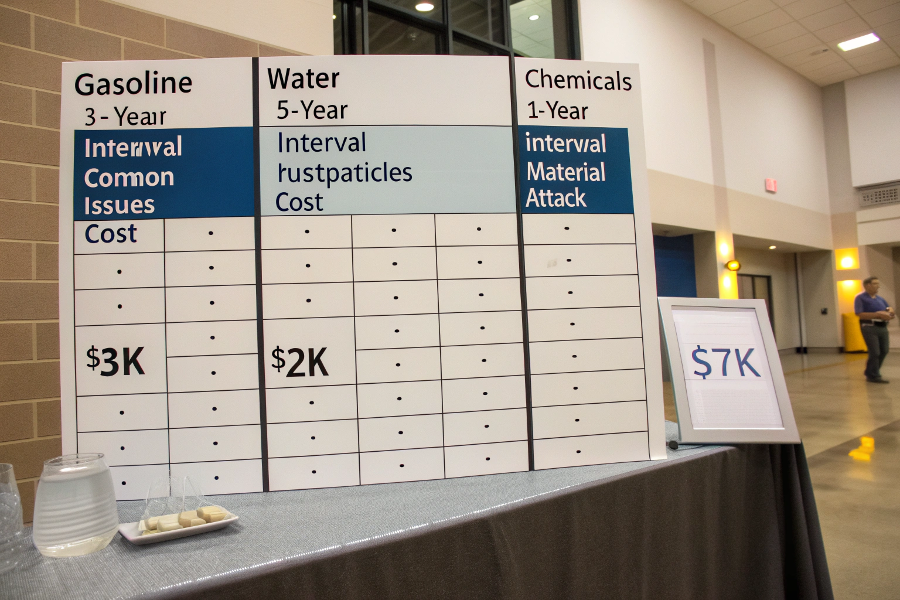

Fluid Type Maintenance Interval Common Issues Cost Gasoline 3 years Varnish build-up $3k Water 5 years Rust particles $2k Chemicals 1 year Material attack $7k

Wear Patterns

Operational Drawbacks:

- Startup Inertia: Requires minimum flow

- Pressure Drop: 2-15 psi typical

- Material Limits: Exotic alloys costly

Which of the Following Is an Advantage of the Turbine Meter?

Key Differentiators Explained:

Competitive Advantage Table

| Feature | Turbine | Competitor | Impact |

|---|---|---|---|

| Response Time | 100ms | Coriolis: 500ms | Faster control |

| Pulse Resolution | 0.1% | Ultrasonic: 1% | Better batching |

| Pipe Size | ½"-48" | Coriolis: ¼"-6" | Wider range |

| Temperature | -450°F to 840°F | Ultrasonic: 32°F to 300°F | Extreme service |

Unique Strengths:

Custody Transfer

- API Chapter 5.6 compliance

- OIML R117 certification

- Legal-for-trade status

Explosive Areas

- ATEX/IECEx options

- Intrinsically safe

- No power needed

Retrofit Projects

- ANSI flange options

- Compact dimensions

- Minimal piping mods

Standards Compliance

Why Customers Choose Turbines:

- Proven Track Record: 500,000+ installed

- Standardization: API/ASTM support

- Supplier Network: Global parts availability

Conclusion

Turbine flow meters deliver unmatched price/performance for clean liquid measurement (±0.5% accuracy at 1/3 Coriolis cost), yet require careful fluid qualification and maintenance planning. Their 20:1 turndown and millisecond response excel in petroleum (45%), chemical (30%), and aerospace (10%) applications – but bearing wear, viscosity limits, and particulate sensitivity demand rigorous application review before selection.