Plant managers often struggle with accurate compressed air flow measurement, leading to energy waste and inefficient system operation.

Vortex flow meters are ideal for compressed air measurement, offering accuracy up to ±1% in pipes from 15mm to 300mm, with stable performance across varying pressures and temperatures.

Vortex Flow Meter in Compressed Air System

Let me share my experience helping facilities optimize their compressed air systems with vortex flow meters.

What Is A Vortex Flow Meter For Compressed Air?

Many industrial users find it challenging to understand how vortex meters work with compressed air systems.

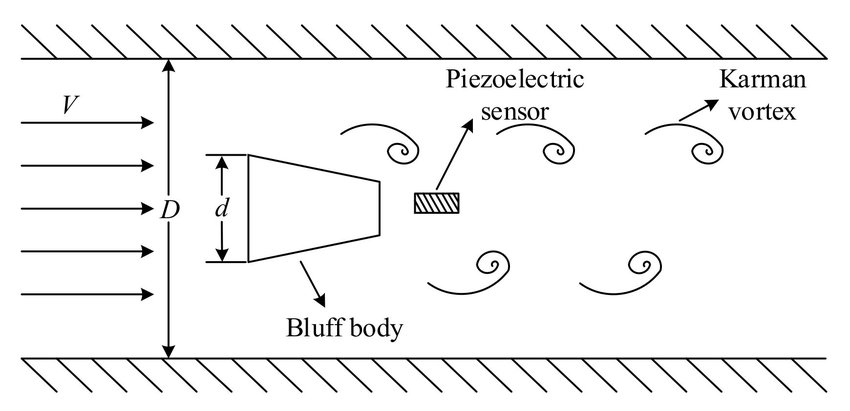

A vortex flow meter for compressed air uses the principle of vortex shedding to measure flow rates, creating alternating low-pressure zones that generate measurable frequencies proportional to flow velocity.

Vortex Flow Meter Operating Principle

From my technical expertise:

Operating Principles

Measurement Process

Stage Description Benefit Vortex Generation Bluff body creates vortices Reliable measurement Signal Detection Sensor captures frequency Accurate readings Flow Calculation Direct proportion to frequency Real-time data Compensation Pressure/temperature correction True flow values Key Components

- Bluff body design

- Piezoelectric sensors

- Signal processing unit

- Temperature/pressure sensors

Application Benefits

- System Integration

- Digital communication

- Energy monitoring

- Leak detection

- System optimization

What Are The Limitations Of Vortex Flow Meter?

Understanding limitations helps prevent application mistakes that could cost time and money.

Vortex flow meters require minimum Reynolds numbers above 20,000, stable flow patterns, and aren’t suitable for very low flows or highly viscous fluids.

Vortex Flow Meter Limitations

Based on my field experience:

Technical Limitations

Operating Constraints

Limitation Impact Solution Low Flow Poor accuracy Size properly Reynolds Number No measurement Check conditions Pipe Size Installation space Plan layout Vibration Signal interference Isolate meter Environmental Factors

- Temperature extremes

- Pressure fluctuations

- Flow disturbances

- Installation space

Application Guidelines

- Best Practices

- Proper sizing

- Installation requirements

- Maintenance schedules

- System monitoring

What Does A Flow Meter Measure In A Compressed Air System?

Understanding flow measurement in compressed air systems is crucial for effective energy management.

Flow meters in compressed air systems measure volumetric or mass flow rates, with options for temperature and pressure compensation to calculate standard or actual flow conditions.

Compressed Air Flow Measurement

Drawing from my expertise:

Measurement Parameters

Flow Variables

Parameter Unit Importance Volumetric Flow ACFM Actual conditions Mass Flow SCFM Standardized flow Pressure PSI/Bar System efficiency Temperature °F/°C Energy content System Metrics

- Energy consumption

- System efficiency

- Leak detection

- Cost allocation

Data Applications

- System Management

- Performance monitoring

- Maintenance planning

- Energy optimization

- Cost reduction

What Is The Best Flowmeter For Air?

Selecting the right flow meter type significantly impacts system performance and reliability.

While vortex meters excel in compressed air applications, the best choice depends on specific requirements including accuracy needs, pressure conditions, and installation constraints.

Air Flow Meter Comparison

From my selection experience:

Comparison Analysis

Technology Options

Type Accuracy Cost Maintenance Vortex ±1% Medium Low Thermal ±2% High Medium Differential ±3% Low High Ultrasonic ±1.5% High Low Selection Criteria

- Flow range requirements

- Accuracy needs

- Installation conditions

- Budget constraints

Implementation Strategies

Best Practices

- Application assessment

- Size optimization

- Installation planning

- Maintenance scheduling

Performance Optimization

- Regular calibration

- System monitoring

- Data analysis

- Efficiency tracking

Conclusion

Vortex flow meters provide reliable compressed air measurement when properly selected and installed, offering an excellent balance of accuracy, maintenance requirements, and cost-effectiveness for industrial applications.