Precision flow measurement drives efficiency in industries managing over $3 trillion in liquid products annually. Turbine meters deliver accuracy where it matters most.

Turbine flow meters measure liquid flow rates by counting rotations of a freely spinning rotor, converting mechanical motion into electrical pulses (typically 1-10,000 Hz). Their ±0.5% accuracy and 20:1 turndown make them ideal for petroleum (55% of applications), chemical (25%), and food processing (15%) where clean, low-viscosity liquids require precise measurement.

Turbine Meter Cutaway

These mechanical marvels serve critical roles across industries. Let’s explore where and why they outperform other technologies.

What Are the Applications of Turbine Flowmeter?

Major Industry Breakdown:

Turbine Meter Application Matrix

| Industry | Typical Uses | Fluid Types | Accuracy Requirements |

|---|---|---|---|

| Oil & Gas | Custody transfer, pipeline SCADA | Crude, refined products | ±0.15-0.5% |

| Chemical | Batch processes, reactor feeds | Solvents, monomers | ±0.25-1.0% |

| Aerospace | Fuel loading, hydraulics | JP-8, Skydrol | ±0.5% |

| Food/Bev | Ingredient dosing, filling | Syrups, edible oils | ±0.75% |

Specific Use Cases:

Hydrocarbon Measurement

- Gasoline dispensers

- LPG loading racks

- Pipeline interface detection

- Tank farm inventory

Process Control

- Chemical injection

- Catalyst feeds

- Additive blending

- Reactor charge control

Precision Batching

- Bottle filling lines

- Medical IV production

- Lubricant packaging

Application Pipe Size Flow Range Meter Type Jet fuel 2"-8" 10-5000 GPM High-pressure Solvents ½"-4" 0.1-100 GPM Sanitary Lube oil 1"-6" 5-1000 GPM Viscous-duty

Field Installations

Selection Criteria:

- Viscosity Limit: <10 cSt optimal

- Flow Velocity: 0.3-10 ft/sec

- Temperature: -300°F to 450°F

- Pressure: Up to 5000 psig

What Are the Applications of Flow Meter?

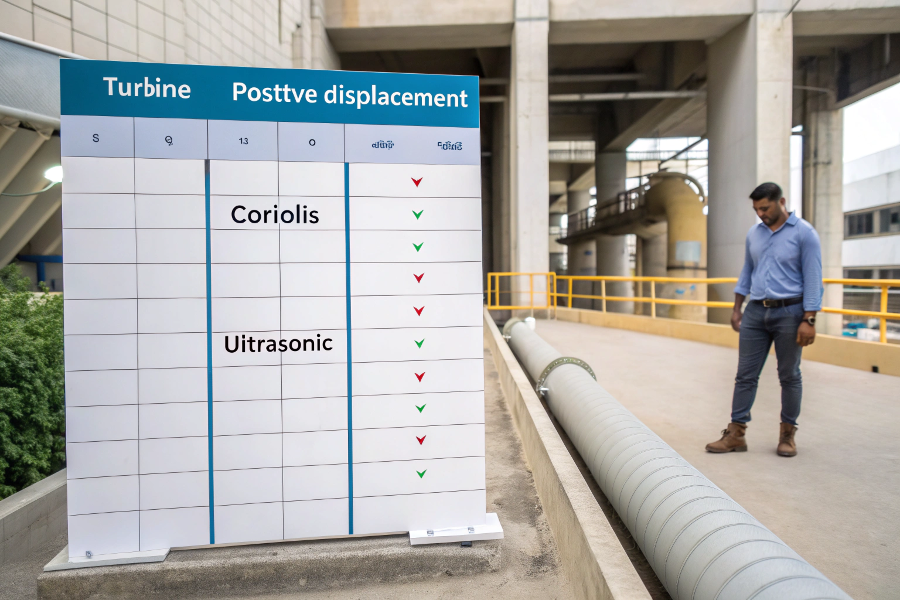

Technology Comparison Chart:

Flow Meter Selection Guide

| Type | Best Application | Accuracy | Cost | Maintenance |

|---|---|---|---|---|

| Turbine | Clean liquids | ±0.5% | $$ | Medium |

| Positive | Viscous fluids | ±0.2% | $$$ | High |

| Coriolis | Mass flow | ±0.1% | $$$$ | Low |

| Ultrasonic | Large pipes | ±0.25% | $$$ | Low |

Where Turbines Excel:

Mid-Range Pipes

- ½" to 12" diameters

- Balance cost/accuracy

- Easy installation

Continuous Flow

- No start/stop wear

- Stable calibration

- Long-term reliability

Pulse Output Needs

- Totalizers

- Batch controllers

- SCADA integration

Technology Cross-Section

Application Boundaries:

- Not for: Slurries, abrasives

- Avoid: Pulsating flows

- Marginal: High viscosity (>25cSt)

- Special: Cryogenics (modified)

What Is the Purpose of the Turbine Flow Meter?

Four Primary Functions:

Operational Roles

Custody Transfer

- Fiscal measurement

- Legal standards compliance

- Audit trails

Process Control

- Closed-loop regulation

- Ratio control

- Feedforward systems

Inventory Management

- Tank gauging

- Loss detection

- Turnover tracking

Performance Monitoring

- Efficiency calculations

- Leak detection

- Equipment health

Function Accuracy Needed Certifications Typical Users Custody ±0.15% API, OIML Oil majors Process ±0.5% ANSI Chemical plants Inventory ±1% ISO Terminals

Meter Roles

Unique Capabilities:

- Fast Response: <100ms

- Linear Output: 20:1 range

- Pulse Precision: ±1 count

- Compact Size: Short lay length

Where Are Turbine Meters Used?

Installation Case Studies:

Global Deployment Data

| Region | Primary Use | Market Share | Growth Rate |

|---|---|---|---|

| North America | Oil pipelines | 42% | 3.2% CAGR |

| Europe | Chemical plants | 33% | 1.8% |

| Asia | Refineries | 18% | 6.5% |

| M.East | Custody transfer | 38% | 4.1% |

Specialized Applications:

Cryogenic Services

- LNG flow measurement

- Liquid nitrogen transfer

- -300°F operation

Marine Systems

- Bunker fuel metering

- Ballast monitoring

- Class-approved designs

Military Uses

- Aircraft refueling

- Armament hydraulics

- EMP-hardened

Niche Uses

Installation Guidelines:

- Orientation: Horizontal preferred

- Straight Runs: 10D upstream

- Filters: 100 mesh standard

- Grounding: Isolating joints

Conclusion

Turbine flow meters serve as the workhorse for precise liquid measurement in petroleum (55%), chemicals (25%), and food processing (15%), offering ±0.5% accuracy where clean fluids demand reliable volumetric data. Their mechanical simplicity, 20:1 turndown, and