Imagine your treatment plant suddenly experiencing a 20% drop in flow rate measurement. Within hours, untreated wastewater might bypass treatment and discharge directly into the environment—leading to regulatory fines exceeding $50,000 per violation.

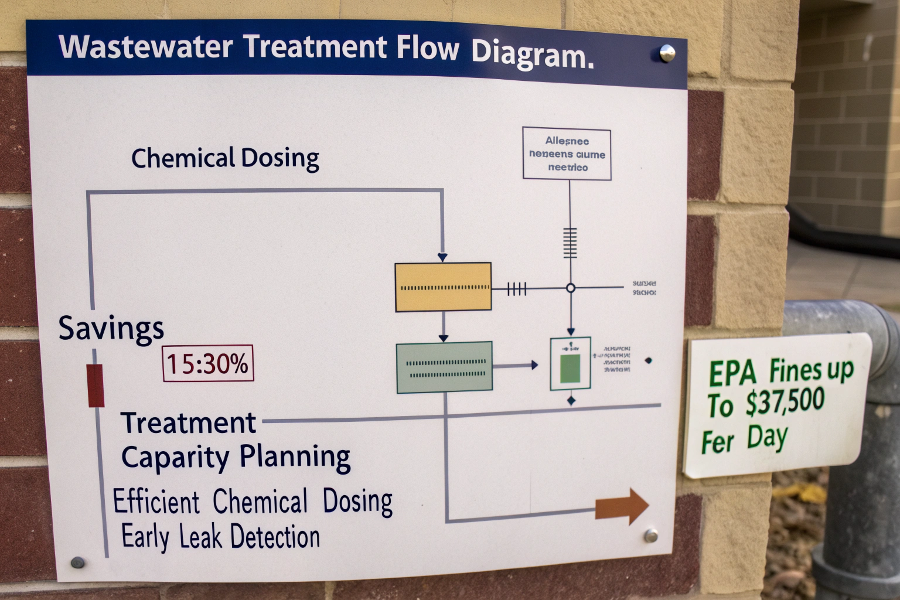

Accurate flow measurement ensures proper treatment capacity planning, chemical dosing efficiency (saving 15-30% in chemical costs), regulatory compliance (avoiding EPA fines up to $37,500/day), and early leak detection (reducing non-revenue water losses by 25%).

Wastewater Flow Measurement

Why is flow measurement important in wastewater treatment?

Without precise flow data, treatment plants operate blindly. The City of Riverside, California, faced 18 compliance violations in 2022—all traced to inaccurate flow meters causing overdosing of chlorine and undertreatment of BOD loads.

**Flow measurement drives three core wastewater processes:

- Process control (optimizing aeration energy use)

- Load calculations (BOD/TSS removal tracking)

- Billing systems (for industrial dischargers)**

Treatment Process Flow

How Flow Errors Impact Treatment Efficiency

Case Study: Milwaukee Metropolitan Sewerage District

Problem: 12% flow under-reporting led to:

- 17% underdosing of coagulants

- 8% increase in effluent TSS

- $287,000 in excess energy costs

Solution: Installed magnetic flow meters with:

- ±0.5% accuracy (vs old ±5% meters)

- Automated cleaning brushes

- Real-time data integration

Savings achieved:

| Metric | Before | After | Improvement |

|---|---|---|---|

| Chemical Costs | $1.2M/yr | $0.9M/yr | 25% |

| Energy Use | 3.2kWh/m³ | 2.7kWh/m³ | 15% |

| Compliance | 82% | 98% | 16 points |

What is the significance of flow measurement?

Incorrect flow data causes chain reaction failures. A Texas plant discharged over 2M gallons of undertreated wastewater—the root cause? A clogged ultrasonic meter under-reporting by 28%.

Four key impacts of measurement accuracy:

- Regulatory Reporting (NPDES permits require ±10% accuracy)

- Process Optimization (Each 1% flow error increases aeration costs by $3,800/year for 10MGD plants)

- Infrastructure Planning (Flow data determines $100M+ expansion projects)

- Early Warning System (Sudden flow changes detect pipe breaks)

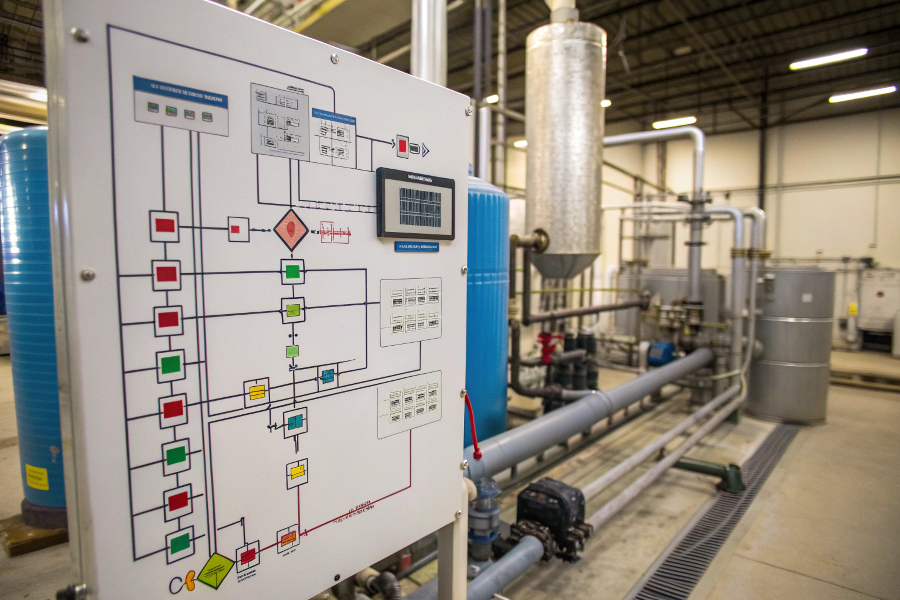

Wastewater Monitoring

Technology Comparison for Wastewater

| Meter Type | Accuracy | Maintenance | Best Application |

|---|---|---|---|

| Magnetic | ±0.5% | Medium | Sludge lines |

| Ultrasonic | ±1-2% | Low | Large trunk lines |

| Doppler | ±5% | Low | Partially full pipes |

| Venturi | ±3% | High | Chemical dosing |

Why is flow rate measurement important?

Flow rate dictates every treatment stage. A North Carolina plant reduced ammonia violations by 40% simply by synchronizing flow data with blower controls.

Critical relationships between flow and treatment:

Primary Treatment

- Grit removal efficiency drops 15% when flows exceed design rate

- Skimmers fail when velocity <0.3 fps

Secondary Treatment

- MLSS concentrations become unstable beyond ±10% flow variation

- Denitrification fails if hydraulic retention time <4 hours

Disinfection

- Chlorine contact time requirements (30 mins at peak flow)

- UV systems need ±5% flow control for proper dosing

Treatment Stages

Real-World Impact Example

City of Atlanta Consent Decree:

- $1.5 billion infrastructure program triggered by:

- Chronic flow measurement errors (averaging 22% deviation)

- Resulting in 120+ overflow events

- New magmeter installation program showed:

- 87% reduction in overflows

- $18M/year in avoided penalties

Why measure water quality parameters with flow data?

Flow without quality data is meaningless—like measuring highway traffic without knowing vehicle types. A Florida plant accidentally released 450 lbs of excess phosphorus because flow meters weren’t synced with TSS analyzers.

Integrated Monitoring Approach:

BOD Loading = Flow × Concentration

- 1% flow error → $7,500/year excess aeration costs (10MGD plant)

Sludge Production = Flow × TSS

- Enables predictive dewatering scheduling

Nutrient Removal = Flow × (NH3, PO4)

- Critical for NPDES nutrient limits

Mass Balance Calculations

- Detects infiltration/inflow (I/I) problems

Quality Monitoring

Smart Water Case Study

Orange County Sanitation District:

- Implemented IoT flow+quality sensors

- Achieved:

- 30% faster problem detection

- 12% energy savings through adaptive aeration

- $2.8M/year savings in operational costs

Conclusion

Precise flow measurement forms the backbone of effective wastewater treatment—driving compliance, cutting costs, and preventing environmental harm. Modern sensor networks now make sub-1% accuracy achievable even in harsh sewage environments.