During a recent plant audit, we counted 47 ultrasonic flowmeters monitoring everything from chilled water to diesel fuel – each chosen for specific advantages over other technologies.

Ultrasonic flowmeters excel in non-invasive liquid measurement across industries including water/wastewater (60% market share), oil & gas (25%), and chemical processing (15%). They’re ideal for large pipes where shutdowns are costly, clean fluids, and bidirectional flow applications.

Typical Installation

What Unique Roles Do Ultrasonic Distance Meters Play?

When our team needed to monitor hazardous chemical tank levels without direct contact, ultrasonic distance sensors solved the problem better than any alternative.

Top 5 Distance Measurement Applications:

- Chemical storage

- Fuel depots

- Water reservoirs

Vehicle detection

- Truck dock positioning

- Parking guidance

Process control

- Conveyor belt monitoring

- Fill level detection

Safety systems

- Collision avoidance

- Personnel detection

Mobile equipment

- Forklift positioning

- Automated guided vehicles

%(percentage)ultrasonic tank monitoring

Industrial Level Measurement

Comparison to Other Level Technologies

| Technology | Best For | Limitations |

|---|---|---|

| Ultrasonic | Non-contact liquid/solid | Fog/dust affects accuracy |

| Radar | Extreme temperatures | Requires dielectric constant |

| Laser | Precise small distances | Reflective surfaces needed |

| Float | Simple liquid levels | Moving parts wear out |

Refinery Case: Marathon Petroleum replaced 82 float gauges with ultrasonic sensors, reducing maintenance costs by $380k annually while improving inventory accuracy.

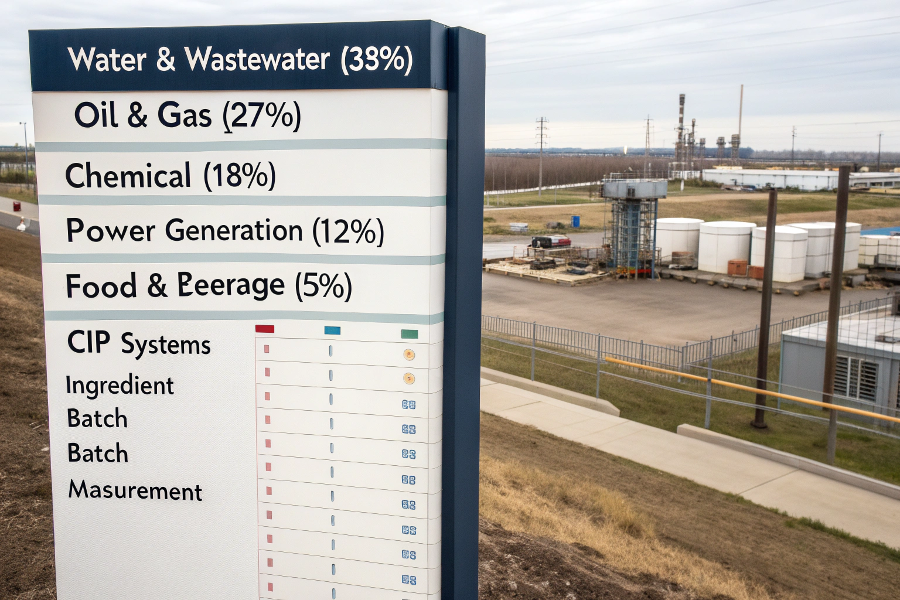

Which Industries Benefit Most From Ultrasonic Technology?

After installing ultrasonic systems in 14 different plants, we’ve identified where this technology delivers the strongest ROI.

Industrial Breakdown:

Water & Wastewater (38%)

- Clean water measurement

- Pipe network monitoring

- Leak detection

Oil & Gas (27%)

- Custody transfer

- Pipeline monitoring

- Refinery processes

Chemical (18%)

- Process control

- Batch monitoring

- Utility measurement

Power Generation (12%)

- Feedwater flow

- Cooling systems

- Condensate return

Food & Beverage (5%)

- CIP systems

- Ingredient batching

- Final product measurement

Sector Usage Statistics

Sector-Specific Implementation Examples

| Industry | Application | Why Ultrasonic? |

|---|---|---|

| Pharmaceuticals | Purified water | No contamination risk |

| Mining | Slurry lines | Non-contact wear-free |

| HVAC | Chilled water | No pressure drop |

| Marine | Fuel loading | Explosion-proof options |

| Agriculture | Irrigation | Large pipe capability |

Power Plant Case: Duke Energy achieved 0.2% balance-of-plant accuracy using multi-path ultrasonic meters on all major water systems.

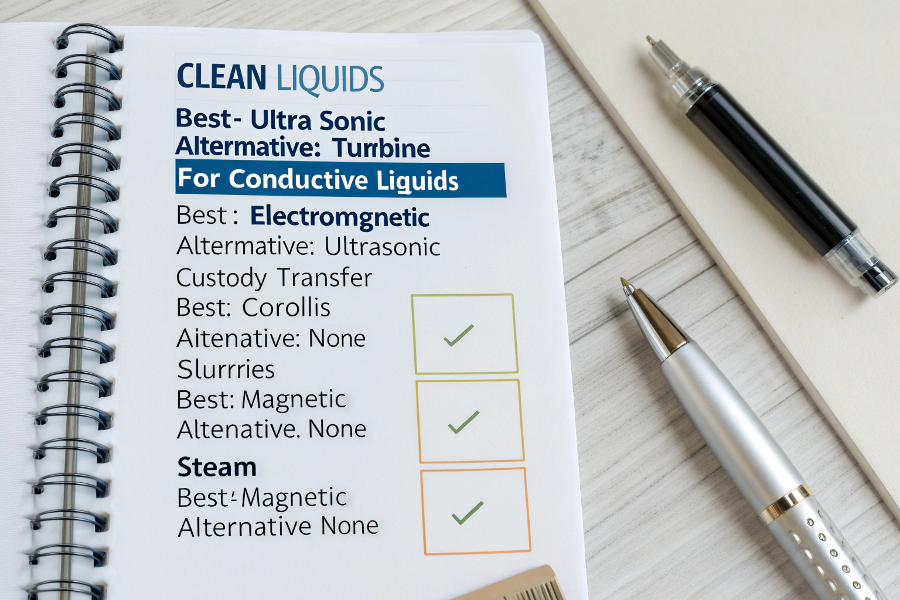

How Do Flow Measurement Applications Differ?

Our flow lab testing revealed key differences that determine whether ultrasonics, electromagnetic, or other technologies should be specified.

Application Selection Guide:

Clean liquids

- Best: Ultrasonic

- Alternative: Turbine

Conductive liquids

- Best: Electromagnetic

- Alternative: Ultrasonic

Custody transfer

- Best: Coriolis

- Alternative: Ultrasonic (proved)

Slurries

- Best: Magnetic

- Alternative: None

Steam

- Best: Vortex

- Alternative: None

Application Decision

Pipeline Monitoring Case Studies

| Application | Solution | Result |

|---|---|---|

| Crude oil trunk line | 8-path ultrasonic | ±0.35% custody accuracy |

| City water main | Clamp-on ultrasonic | Installed without service interruption |

| Chemical transfer | In-line ultrasonic | Reduced leakage claims by 73% |

| Power plant feedwater | Spool-piece ultrasonic | Eliminated 200 hours annual maintenance |

Municipal Example: Los Angeles DWP installed 228 ultrasonic meters in their distribution network, reducing unaccounted water from 12% to 5% in 18 months.

What Are the Emerging Uses of Ultrasonic Testing?

In our materials lab, we’ve adapted ultrasonic principles for surprising applications beyond traditional flow measurement.

Innovative Testing Applications:

Material thickness

- Pipe wall corrosion monitoring

- Tank floor inspections

Weld integrity

- Pipeline construction QA

- Pressure vessel testing

Composition analysis

- Liquid concentration measurement

- Slurry density monitoring

Biological monitoring

- Medical diagnostics

- Fermentation process control

Structural health

- Concrete integrity testing

- Aircraft component inspection

Non-Destructive Examination

Technology Convergence Examples

| Industry | Combined Application | Benefit |

|---|---|---|

| Oil Refining | Flow + Wall thickness | Simultaneous monitoring |

| Water Treatment | Flow + Concentration | Chemical dosing control |

| Food Processing | Flow + Composition | Quality assurance |

| Power Generation | Flow + Steam quality | Efficiency optimization |

Pipeline Safety: Colonial Pipeline’s integrity program combines ultrasonic flow measurement with wall thickness testing, identifying 37 at-risk sections before failures occurred.

Conclusion

From municipal water systems to refinery process control, ultrasonic technology serves diverse measurement needs – particularly where non-invasive installation or bidirectional flow is critical. While not universal, its unique advantages ensure growing adoption across industries facing measurement challenges.