Your electromagnetic flow meter (EMF) works hard daily – but how do you know when it’s no longer measuring accurately? Watch for these critical failure symptoms.

Replace your EMF when measurements drift >2% from reference checks, power cycling fails to reset errors, or liner/electrode damage appears. Prolonged use beyond these failure points risks regulatory non-compliance and process control failures costing 10x more than timely replacement.

Failed EMF Inspection

Here’s how to diagnose terminal EMF issues before they impact operations.

What Are the Symptoms of EMF Overload?

Your meter sends distress signals long before complete failure.

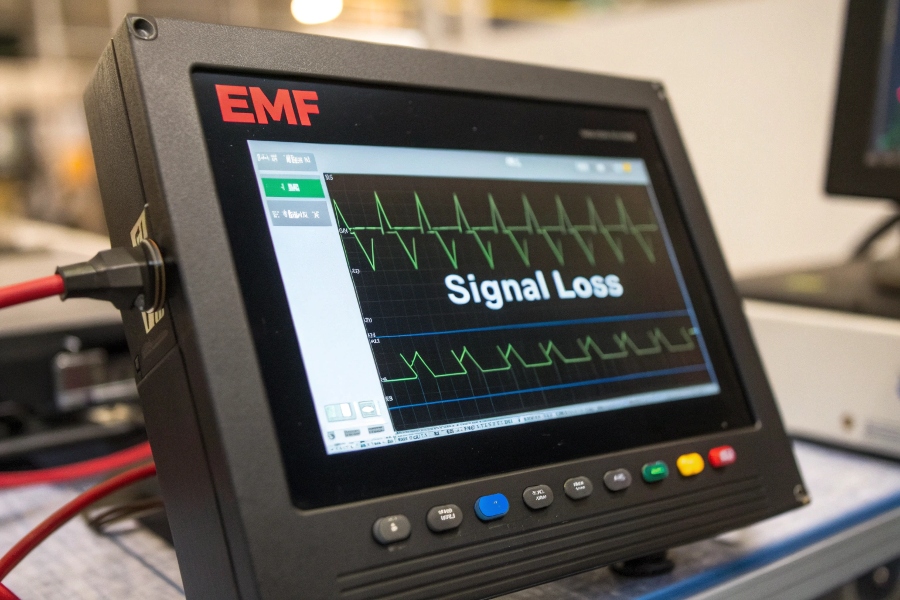

EMF overload shows as erratic pulses (>10% flow spikes), continuous "Signal Loss" alarms, or stuck-at-zero readings despite flow. These indicate dying preamplifiers or electrical noise penetrating damaged cables – issues requiring immediate attention to prevent measurement blackouts during critical processes.

Troubleshooting Display

Recognize progressive failure stages:

EMF Degradation Timeline

| Stage | Symptoms | Corrective Action |

|---|---|---|

| Early | ±1-2% drift | Recalibrate |

| Mid | Temporary signal drops | Replace cables |

| Late | Frozen display | Replace meter |

| Critical | Sparking/overheating | Emergency shutdown |

What Is an Unsafe Amount of EMF?

Not all meter behaviors are created equal.

Dangerous EMF conditions include visible arcing between terminals, casing temperatures exceeding 60°C (140°F), or ground faults tripping breakers – all requiring immediate power disconnection. These pose serious shock/explosion risks, especially in hazardous areas where intrinsic safety barriers may be compromised.

Hazard Identification

Prioritize these safety checks:

EMF Hazard Assessment Matrix

Electrical Risks

- Check insulation resistance >100MΩ

- Verify ground continuity <1Ω

Process Risks

- Confirm no leakage at connections

- Inspect for chemical corrosion

Environmental Risks

- Ensure no explosive gas accumulation

- Check ambient temperature ratings

What Are the Neurological Symptoms of EMF?

People often misunderstand biological EMF effects.

While industrial EMFs pose no direct neurological risks (operating at harmless microtesla levels), field technicians report dizziness/nausea near severely malfunctioning meters – usually caused by secondary factors like ozone emission from arcing components or psychological stress during troubleshooting high-value equipment failures.

Field Service Scenario

Separate fact from fiction:

EMF Health Impact Clarifications

| Concern | Reality | Precaution |

|---|---|---|

| Magnetic fields | 1/1000th of MRI strength | No special PPE needed |

| Electrical shocks | Possible if housing damaged | Always de-energize first |

| Chemical exposure | Only if seals fail | Wear gloves during inspections |

| Radiation | Zero ionizing radiation | No shielding required |

How Worried Should I Be About EMF?

Risk depends on application criticality.

Prioritize EMF replacement in: 1) Custody transfer applications (legal/financial risk), 2) Safety systems (cooling water monitoring), or 3) Continuous processes where 2% error could waste $10k/day in chemicals. Non-critical applications may tolerate temporary patching until scheduled shutdowns.

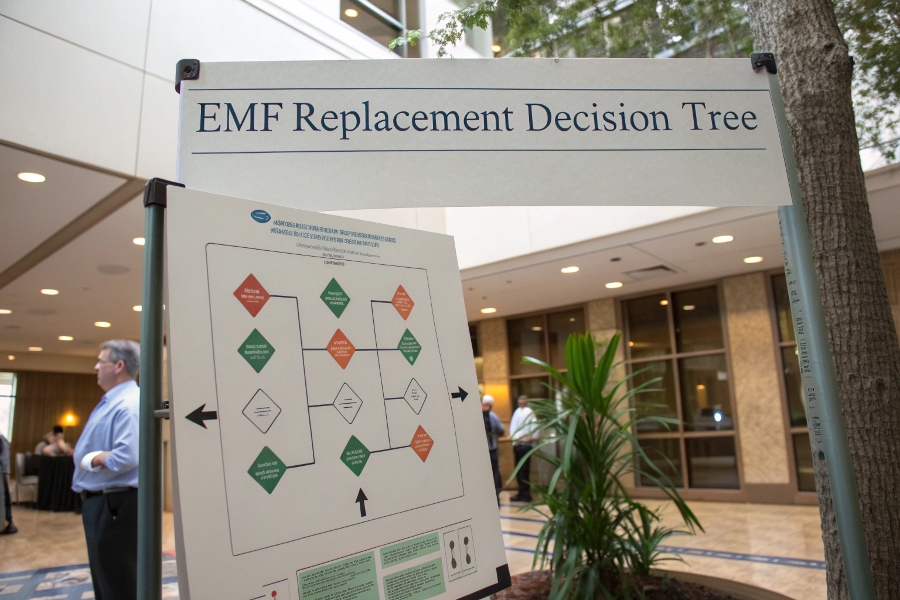

Replacement Decision Tree

Make data-driven decisions:

EMF Replacement Cost-Benefit Analysis

| Factor | Replace Now | Monitor | Patch Temporarily |

|---|---|---|---|

| Accuracy Drift | >2% | 1-2% | <1% |

| Safety Risk | Present | Potential | None |

| Process Impact | Critical | Moderate | Minor |

| Lead Time | 2 weeks | N/A | 48hrs |

| Budget Cycle | Emergency | Next FY | Stopgap |

Proactive Maintenance Strategies

Extend EMF lifespan wisely.

Annual Inspections

- Megger tests on excitation coils

- Electrode resistance checks

Predictive Monitoring

- Track baseline noise levels

- Log calibration drift trends

Spare Parts Inventory

- Keep spare preamplifiers onsite

- Stock compatible grounding rings

Conclusion

Recognizing terminal EMF failure signs prevents costly process upsets and safety incidents. While meters often last 15+ years, aggressive fluids or electrical faults may require earlier replacement. When in doubt, compare against a portable reference meter – if inconsistencies exceed your process tolerances, it’s time for a new EMF.