Choosing between radar and ultrasonic level sensors can be challenging, especially when both seem suitable for your application.

Radar sensors use electromagnetic waves and excel in harsh conditions, while ultrasonic sensors use sound waves and are more cost-effective. Each has distinct advantages for specific applications.

Radar vs Ultrasonic Sensor Overview

From my years of experience implementing both technologies, let me share a detailed comparison.

What Are The Main Advantages of Using Radar Sensors Over Ultrasonic Sensors?

Many industries are shifting from ultrasonic to radar technology.

Radar sensors offer better accuracy, longer measurement range, and superior performance in challenging environments like steam, dust, and temperature variations.

Radar Sensor Advantages

Here’s what I’ve learned from field implementations:

Performance Advantages

Environmental Immunity

Factor Radar Ultrasonic Temperature Stable Affected Vapor Excellent Poor Pressure Immune Sensitive Dust Penetrates Interferes Measurement Capabilities

- Higher accuracy (±2mm)

- Longer range (up to 100m)

- Faster response time

- Better stability

Application Benefits

Process Conditions

- High-temperature operation

- Vacuum compatibility

- Turbulent surface handling

- Interface measurement

Installation Flexibility

- Smaller dead zones

- Various antenna options

- Remote electronics

- Multiple communication protocols

These advantages make radar sensors ideal for challenging industrial applications.

What Are The Disadvantages of Radar Level Sensors?

Understanding limitations helps make informed decisions.

Radar sensors have higher initial costs, require more expertise for setup, and may face challenges with foam or low-dielectric materials.

Radar Sensor Limitations

Based on my implementation experience:

Technical Limitations

Application Challenges

Challenge Impact Solution Foam Signal scatter Special algorithms Low dielectric Weak signal Larger antenna Small tanks Dead zone Careful mounting Complex geometry False echoes Echo mapping Implementation Issues

- Complex configuration

- Expert knowledge needed

- Special tools required

- Training investment

Economic Considerations

Cost Factors

- Higher initial investment

- Installation expertise

- Maintenance training

- Spare parts inventory

Operational Aspects

- Setup time

- Calibration requirements

- Documentation needs

- Support resources

Understanding these limitations helps in proper planning and implementation.

Is Radar The Same As Ultrasonic?

This common question reveals fundamental differences.

No, radar uses electromagnetic waves at GHz frequencies, while ultrasonic uses sound waves at kHz frequencies. This creates distinct operational characteristics.

Radar vs Ultrasonic Technology

Let me explain the key differences:

Fundamental Differences

Operating Principles

Aspect Radar Ultrasonic Wave type Electromagnetic Sound Frequency 6-26 GHz 20-200 kHz Speed Light speed Sound speed Medium dependency Low High Technology Impact

- Measurement accuracy

- Environmental sensitivity

- Application range

- Installation requirements

Performance Variations

Environmental Effects

- Temperature influence

- Pressure changes

- Vapor presence

- Dust impact

Application Considerations

- Material properties

- Process conditions

- Measurement needs

- Budget constraints

These differences affect technology selection.

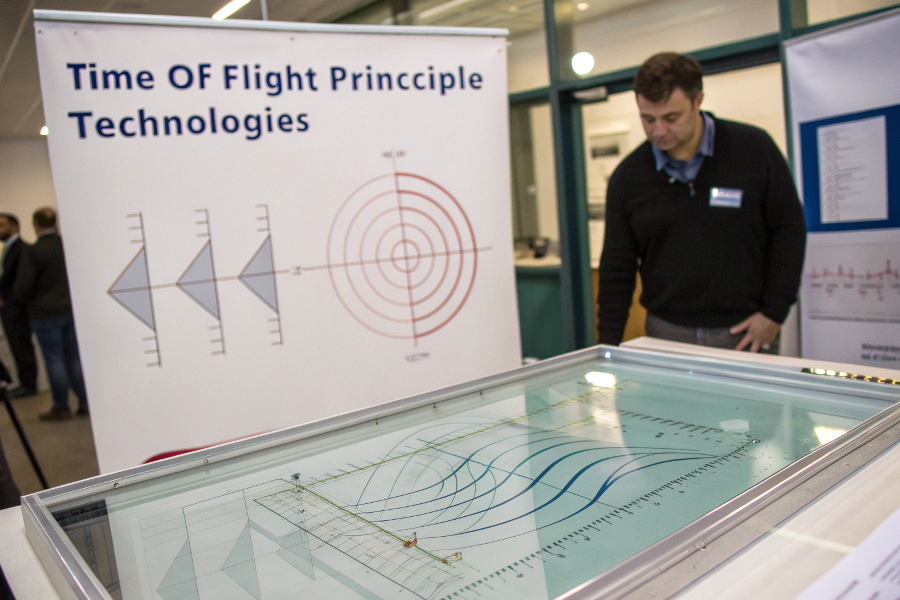

How Do Ultrasonic Or Radar Devices Measure Levels?

Understanding measurement principles helps optimize performance.

Both technologies use time-of-flight principle, measuring how long it takes for emitted waves to return after reflecting off the material surface.

Level Measurement Principles

From my experience:

Measurement Process

Basic Operation

Step Radar Ultrasonic Emission EM waves Sound waves Propagation Through air Through atmosphere Reflection From surface From interface Reception Antenna Transducer Signal Processing

- Time calculation

- Echo analysis

- Interference filtering

- Level conversion

Technology Specifics

Radar Methods

- FMCW

- Pulse radar

- Guided wave

- Free space

Ultrasonic Features

- Temperature compensation

- Echo discrimination

- Automatic gain control

- False echo suppression

Understanding these principles ensures optimal implementation.

Conclusion

Both radar and ultrasonic sensors have their place in level measurement. Radar excels in harsh conditions and accuracy but costs more, while ultrasonic offers cost-effective solutions for simpler applications.