Inaccurate diesel fuel monitoring can lead to unexpected shortages, operational disruptions, and costly emergency refills.

Ultrasonic level sensors provide accurate, non-contact measurement for diesel tanks, offering continuous monitoring with ±0.25% accuracy. They’re ideal for fuel inventory management and consumption tracking.

Ultrasonic Level Sensor on Diesel Tank

Let me share insights from my experience in implementing fuel monitoring solutions across various industries.

How to Measure Diesel Tank Level?

Proper diesel level measurement is crucial for operational efficiency.

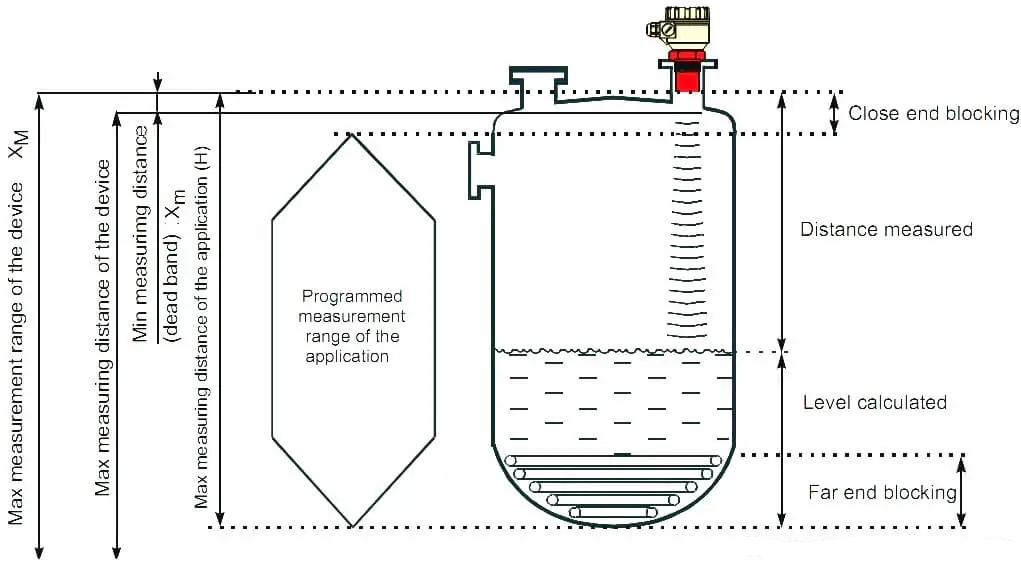

Install an ultrasonic sensor on the tank top, ensuring proper alignment and calibration. The sensor measures distance to fuel surface using sound waves, converting it to volume based on tank dimensions.

Diesel Tank Measurement Setup

From my installation experience:

Installation Steps

Pre-Installation Planning

- Tank measurements

- Mounting location selection

- Cable routing

Hardware Setup

- Sensor mounting

- Power connection

- Signal wiring

Configuration Requirements

Tank Parameters

Parameter Description Height Total tank height Shape Cylindrical/rectangular Volume Total capacity Dead zone Minimum measurement distance Calibration Settings

- Empty tank level

- Full tank level

- Volume calculations

These steps ensure accurate measurement and reliable operation.

What Should I Avoid with Ultrasonic Level Sensors?

Understanding potential issues prevents measurement errors.

Avoid mounting sensors near tank walls, inlets, or areas with turbulence. Prevent exposure to extreme temperatures and ensure proper ventilation to minimize vapor interference.

Ultrasonic Sensor Installation Warnings

Based on my troubleshooting experience:

Common Mistakes

Installation Errors

- Improper alignment

- Insufficient clearance

- Unstable mounting

Environmental Issues

- High temperature exposure

- Excessive vapor presence

- Direct sunlight

Best Practices

- Regular maintenance checks

- Proper cable protection

- Signal quality monitoring

- Temperature compensation

Following these guidelines maximizes sensor performance.

What Type of Sensor Is Used in Fuel Oil Tank Level Monitoring?

Selecting the right sensor ensures reliable measurement.

Ultrasonic sensors are widely used for fuel monitoring, offering non-contact measurement and digital output. Alternative options include guided wave radar, magnetostrictive, and pressure sensors.

Fuel Tank Sensor Types

Drawing from my field experience:

Sensor Types Comparison

Ultrasonic Sensors

- Non-contact operation

- Easy maintenance

- Cost-effective

Guided Wave Radar

- High accuracy

- Works with foam

- Higher cost

Magnetostrictive

- Excellent accuracy

- Direct measurement

- Complex installation

Selection Criteria

- Tank size

- Budget constraints

- Accuracy requirements

- Environmental conditions

These factors help determine the optimal sensor choice.

How Does an Ultrasonic Fuel Level Sensor Work?

Understanding operation principles ensures proper implementation.

Ultrasonic sensors emit high-frequency sound waves (20-200 kHz) that bounce off the fuel surface. The time between emission and echo reception determines the fuel level.

Ultrasonic Sensor Operating Principle

From my implementation experience:

Operating Process

Signal Generation

Step Action 1 Wave emission 2 Surface reflection 3 Echo reception 4 Time calculation Measurement Conversion

- Distance calculation

- Volume computation

- Temperature compensation

Signal Processing

Echo Analysis

- Signal filtering

- Noise reduction

- Quality verification

Output Generation

- Level indication

- Volume calculation

- Alarm monitoring

Understanding these principles helps optimize sensor performance.

Conclusion

Ultrasonic level sensors offer reliable diesel tank monitoring when properly installed and maintained. Understanding their operation, limitations, and best practices ensures accurate fuel level measurement and efficient inventory management.