Many industrial processes face measurement challenges with high-temperature fluids, leading to costly errors and equipment damage.

Ultrasonic flow meters typically operate reliably from -40°C to 200°C with standard transducers, while special high-temperature versions can handle up to 600°C with proper installation.

Temperature Operating Ranges for Flow Meters

I’ve helped numerous customers solve high-temperature measurement challenges, and here’s what I’ve learned.

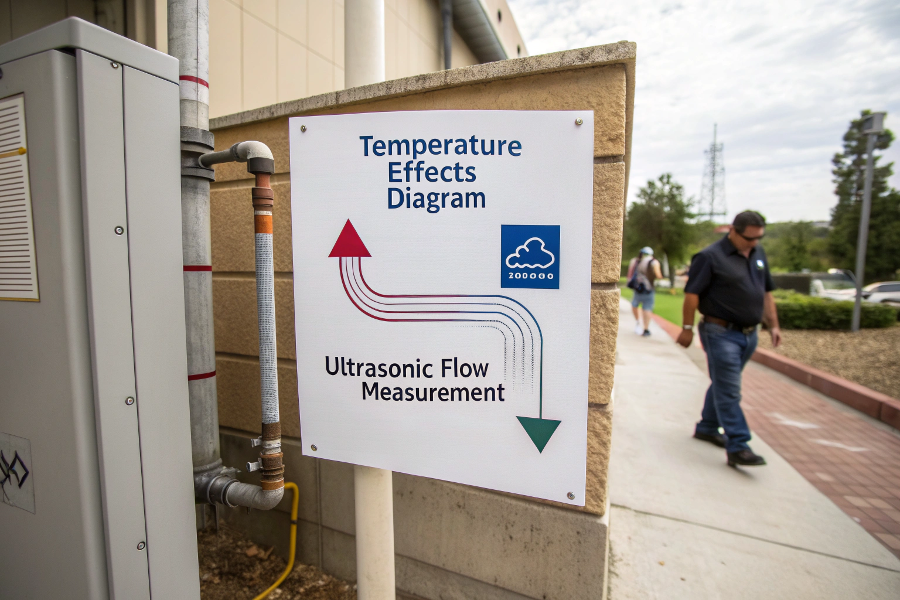

How Does Temperature Affect the Ultrasonic Flow Meter?

Temperature variations can significantly impact measurement accuracy and sensor performance.

Temperature affects ultrasonic flow measurement by changing fluid density, sound velocity, and pipe dimensions, requiring proper compensation for accurate readings.

Temperature Effects on Flow Measurement

From my field experience:

Temperature Impact Factors

Critical Parameters

Parameter Effect Solution Sound Speed Varies with temp Auto compensation Fluid Density Changes Real-time adjustment Pipe Expansion Dimensional changes Material correction Signal Strength Degrades at extremes Enhanced processing Performance Considerations

- Signal attenuation

- Thermal drift

- Response time

- Calibration stability

Compensation Methods

Technical Solutions

- Temperature sensors

- Material compensation

- Dynamic calibration

- Signal processing

Installation Requirements

- Insulation needs

- Mounting considerations

- Cable protection

- Cooling systems

What are the Limitations of Ultrasonic Flow Meter?

Not understanding operational limits can lead to measurement failures and equipment damage.

Ultrasonic flow meters are limited by extreme temperatures, high particulate content, gas bubbles, and minimum flow velocities.

Flow Meter Limitations Overview

Based on my technical expertise:

Operating Limitations

Key Constraints

Limitation Impact Mitigation Temperature Range Signal quality Special materials Flow Profile Accuracy Installation position Gas Bubbles Signal loss Entrained gas removal Particulates Signal scatter Alternative mounting Application Boundaries

- Minimum flow rates

- Maximum temperatures

- Fluid properties

- Installation requirements

Solution Strategies

Design Approaches

- High-temp materials

- Enhanced electronics

- Cooling systems

- Signal processing

Installation Methods

- Strategic positioning

- Thermal isolation

- Protection systems

- Maintenance access

What is the Temperature Range of a Mass Flow Meter?

Using mass flow meters outside their temperature range can result in measurement errors and equipment failure.

Mass flow meters typically operate from -50°C to 350°C, with specialized versions handling up to 400°C for specific applications.

Drawing from my product knowledge:

Temperature Capabilities

Type-Specific Ranges

Meter Type Standard Range Extended Range Coriolis -50 to 350°C Up to 400°C Thermal -40 to 200°C Up to 450°C Direct Mass -40 to 150°C Up to 200°C Hybrid -40 to 250°C Up to 350°C Application Considerations

- Process requirements

- Material limitations

- Accuracy needs

- Cost factors

Implementation Guidelines

Selection Criteria

- Process conditions

- Required accuracy

- Installation environment

- Maintenance needs

Performance Factors

- Temperature stability

- Response time

- Calibration requirements

- Long-term reliability

What is a Turbine Flow Meter High Temperature?

Incorrect turbine meter selection for high-temperature applications can lead to premature failure and inaccurate measurements.

High-temperature turbine flow meters can operate up to 540°C with special bearings and materials, though most standard versions are limited to 200°C.

High Temperature Turbine Meter Design

From my experience with high-temperature applications:

Design Specifications

Material Requirements

Component Material Temperature Limit Body 316SS/Hastelloy Up to 540°C Bearings Ceramic/Carbon Up to 450°C Rotor Special Alloys Up to 540°C Seals Graphite/Metal Up to 540°C Construction Features

- Heat dissipation

- Thermal expansion

- Bearing design

- Rotor balance

Application Guidelines

Installation Requirements

- Thermal isolation

- Support structure

- Cooling provisions

- Maintenance access

Performance Monitoring

- Bearing wear

- Calibration drift

- Signal quality

- Temperature effects

Conclusion

Successful high-temperature flow measurement requires careful consideration of meter type, material selection, and installation methods, along with proper maintenance and monitoring procedures.