Selecting the wrong flow meter type can lead to significant measurement errors and wasted investment in your process monitoring system.

Clamp-on ultrasonic flow meters are non-invasive devices that attach to the outside of pipes, offering accuracies of ±1-2% with proper installation and suitable conditions.

Clamp-on Flow Meter Installation

Let me share my experience helping customers choose and install clamp-on ultrasonic flow meters.

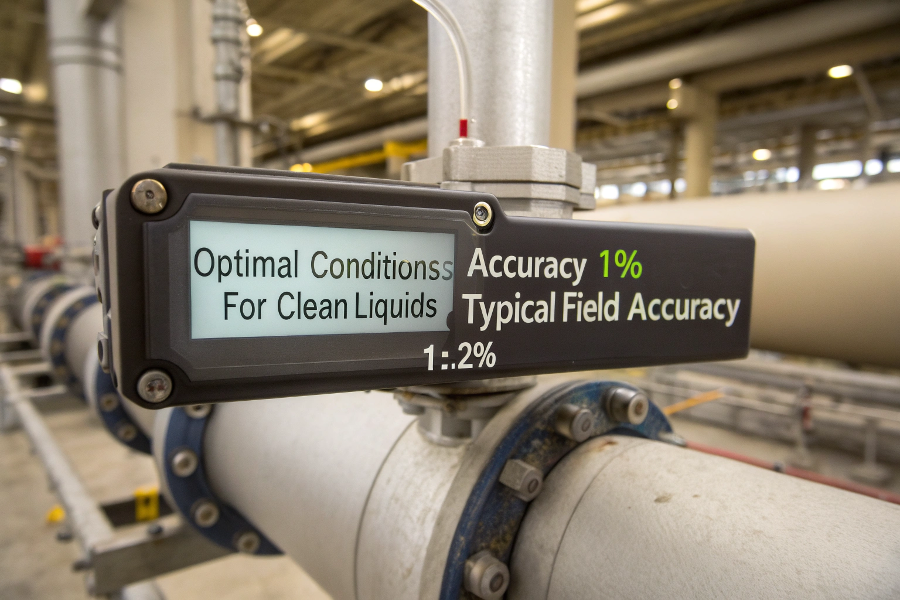

How Accurate is the Clamp-on Ultrasonic Flow Meter?

Many users worry about accuracy when considering non-invasive measurement methods.

Under optimal conditions, clamp-on ultrasonic flow meters can achieve accuracies of ±1% for clean liquids, though typical field accuracy ranges from ±1-2%.

Accuracy Influencing Factors

From my field experience:

Accuracy Influencing Factors

-

Installation Conditions

Factor Impact Optimal Condition Pipe Straightness Critical 10D upstream, 5D downstream Pipe Surface High Clean, smooth surface Fluid Profile Significant Fully developed flow Signal Strength Important Good acoustic coupling -

Environmental Effects

- Temperature variations

- Vibration levels

- Electromagnetic interference

- Ambient conditions

Performance Optimization

-

Best Practices

- Proper site selection

- Correct sensor mounting

- Regular maintenance

- Calibration verification

-

Application Considerations

- Fluid properties

- Flow regime

- Pipe characteristics

- Operating conditions

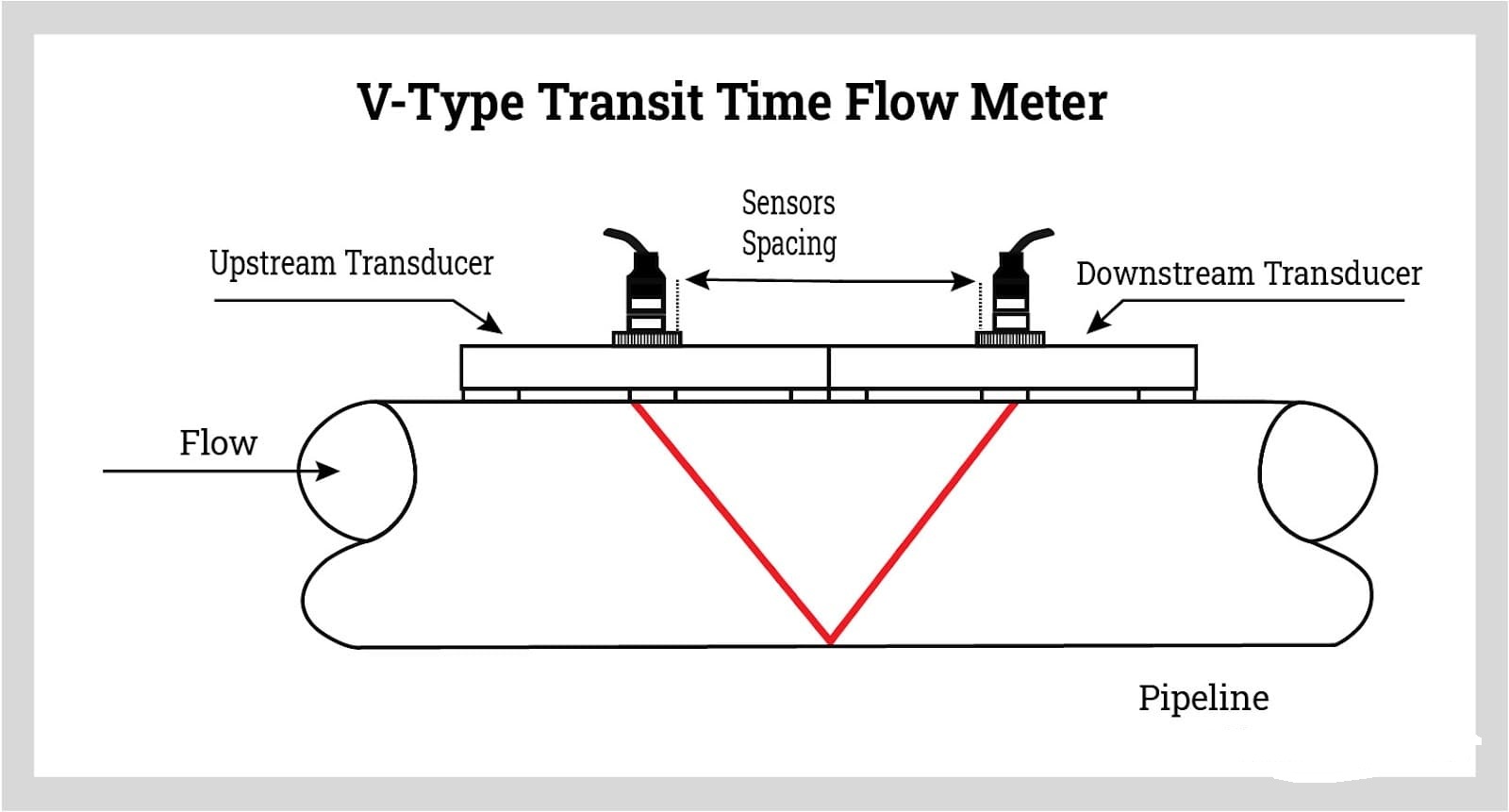

How Do Clamp-on Ultrasonic Flow Meters Work?

Understanding the working principle helps avoid common installation and operation mistakes.

Clamp-on meters use ultrasonic signals transmitted through the pipe wall and fluid, measuring either transit-time differences or Doppler frequency shifts to determine flow rate.

Ultrasonic Flow Measurement Principle

Based on my technical expertise:

Operating Principles

-

Measurement Methods

Method Application Principle Transit-Time Clean Fluids Time Difference Doppler Dirty Fluids Frequency Shift Hybrid Mixed Services Dual Mode WideBeam Challenging Apps Multi-Path -

Signal Processing

- Acoustic path

- Time measurement

- Signal correlation

- Flow calculation

Implementation Details

-

Installation Requirements

- Sensor positioning

- Acoustic coupling

- Cable routing

- Signal verification

-

Setup Parameters

- Pipe properties

- Fluid characteristics

- Operating conditions

- Calibration factors

What Are the Disadvantages of Clamp-on Ultrasonic Flow Meter?

Overlooking potential limitations can lead to disappointing performance and unexpected issues.

Main disadvantages include sensitivity to installation conditions, reduced accuracy compared to inline meters, and dependence on pipe wall condition and material.

Common Challenges with Clamp-on Meters

Drawing from my troubleshooting experience:

Common Challenges

-

Installation Issues

Challenge Impact Solution Pipe Access Limited Site Planning Surface Condition Signal Quality Surface Prep Mounting Stability Proper Brackets Alignment Accuracy Careful Setup -

Operational Limitations

- Temperature effects

- Signal attenuation

- Flow profile sensitivity

- Material compatibility

Mitigation Strategies

-

Installation Solutions

- Proper site selection

- Surface preparation

- Quality mounting hardware

- Expert installation

-

Performance Optimization

- Regular maintenance

- Signal monitoring

- Parameter verification

- Periodic calibration

What is the Difference Between Inline and Clamp-on Ultrasonic Flow Meter?

Making the wrong choice between inline and clamp-on meters can result in unnecessary costs or poor performance.

Inline meters are installed by cutting into the pipe and offer higher accuracy (±0.5%), while clamp-on meters install externally with slightly lower accuracy but no process interruption.

Inline vs Clamp-on Comparison

From my product knowledge:

Key Differences

-

Comparison Table

Feature Inline Clamp-on Accuracy ±0.5% ±1-2% Installation Process Interruption Non-invasive Cost Higher Lower Maintenance More Complex Simpler -

Application Considerations

- Process requirements

- Installation constraints

- Budget limitations

- Accuracy needs

Selection Guidelines

-

Decision Factors

- Application criticality

- Installation access

- Maintenance requirements

- Cost constraints

-

Performance Expectations

- Accuracy needs

- Reliability requirements

- Operating conditions

- Long-term stability

Conclusion

Clamp-on ultrasonic flow meters offer a versatile, non-invasive solution for flow measurement, providing good accuracy and ease of installation when properly selected and installed for the specific application.