Many industrial users struggle with selecting the right flow meter for their water measurement needs, often leading to costly mistakes and inefficient operations.

Vortex flow meters are excellent for water applications, offering 1% accuracy, no moving parts, and reliable performance in pipe sizes from 15mm to 300mm, making them ideal for clean liquid measurement.

Vortex Flow Meter in Water Application

As someone who has helped numerous customers optimize their water flow measurements, I want to share some key insights about vortex flow meters.

What Is A Vortex Flow Meter Used For?

Plant engineers often face challenges when choosing between different flow measurement technologies for their applications.

Vortex flow meters are primarily used for measuring clean liquids, gases, and steam flows, with particular effectiveness in water applications where reliable measurement under varying conditions is crucial.

Vortex Flow Meter Applications

From my extensive field experience:

Common Applications

Industry Sectors

Sector Application Benefits Water Treatment Process monitoring Reliable in continuous operation Power Generation Cooling systems Handles high temperatures Chemical Process control Chemical compatibility HVAC Chilled water Cost-effective solution Process Requirements

- Flow rate monitoring

- Energy consumption

- Batch control

- Distribution systems

Operating Principles

Measurement Method

- Vortex shedding phenomenon

- Strouhal number relationship

- Signal processing

- Flow calculation

Key Features

- No moving parts

- Low maintenance

- Long-term stability

- Digital output options

How Accurate Is A Vortex Flow Meter?

When accuracy matters in water flow measurement, understanding the capabilities of vortex meters becomes crucial.

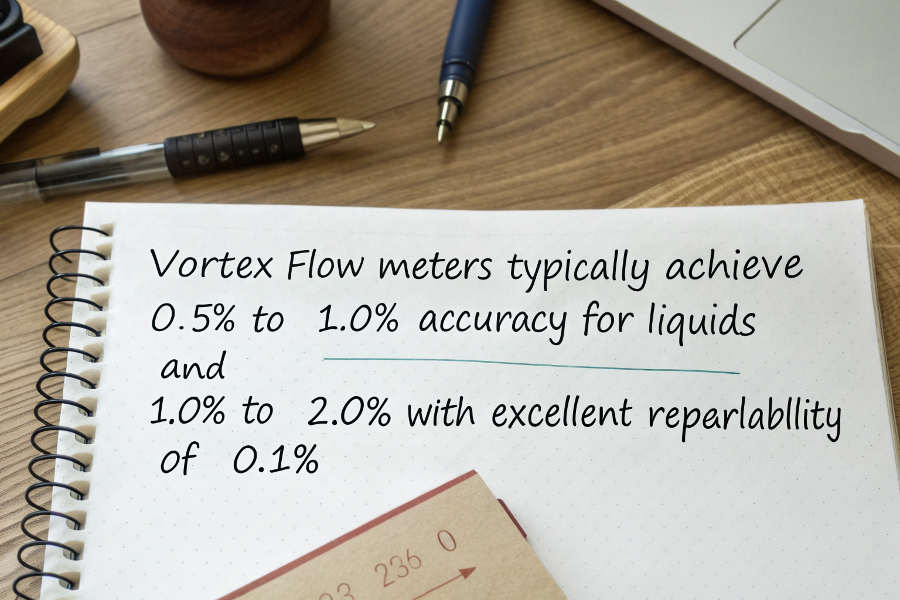

Vortex flow meters typically achieve ±1% of reading accuracy for liquids, with some premium models reaching ±0.5% accuracy under optimal conditions.

Vortex Flow Meter Accuracy Chart

Based on my calibration experience:

Accuracy Factors

Performance Parameters

Parameter Typical Value Impact on Accuracy Linearity ±0.5% Direct measurement accuracy Repeatability ±0.2% Consistency of readings Turndown Ratio 20:1 Operating range Response Time <1 second Real-time monitoring Influencing Factors

- Flow profile

- Installation effects

- Process conditions

- Maintenance status

Optimization Techniques

- Installation Considerations

- Proper straight runs

- Orientation requirements

- Vibration isolation

- Temperature effects

What Is The Difference Between Mass Flow Meter And Vortex Flow Meter?

Understanding the distinctions between mass and vortex flow meters helps in making informed selection decisions.

Mass flow meters directly measure fluid mass flow, while vortex meters measure volumetric flow and require additional compensation for mass flow calculations.

Let me share my practical knowledge:

Technology Comparison

Key Differences

Feature Mass Flow Meter Vortex Flow Meter Measurement Direct mass flow Volumetric flow Installation Size/orientation sensitive Straight run required Cost Higher Lower Maintenance More complex Simpler Application Considerations

- Process requirements

- Budget constraints

- Installation space

- Maintenance capabilities

Selection Guidelines

- Decision Factors

- Measurement needs

- Process conditions

- Cost considerations

- Maintenance resources

What Are The Requirements For A Vortex Flow Meter?

Proper installation and operating conditions are essential for optimal vortex meter performance.

Vortex flow meters require minimum Reynolds numbers above 20,000, adequate straight pipe runs, and proper sizing for the application’s flow range.

%(percentage)vortex-requirements

Vortex Flow Meter Requirements

Vortex Flow Meter Requirements

From my installation experience:

Installation Requirements

Physical Parameters

Requirement Specification Purpose Upstream Run 15-30D Flow profile development Downstream Run 5-10D Flow stability Reynolds Number >20,000 Vortex formation Flow Range 20:1 turndown Measurement range Environmental Considerations

- Temperature limits

- Pressure ratings

- Vibration levels

- Material compatibility

Operating Conditions

Process Parameters

- Flow velocity

- Fluid properties

- Operating pressure

- Temperature range

Maintenance Requirements

- Regular calibration

- Sensor cleaning

- Electronics check

- Documentation

Conclusion

Vortex flow meters excel in water applications due to their accuracy, reliability, and low maintenance requirements, making them a cost-effective choice when properly sized and installed according to manufacturer specifications.