Many process engineers face challenges with unreliable level detection in tough environments where traditional technologies fail.

Tuning fork level switches use vibration frequency changes to detect liquid or solid levels, providing reliable point level detection even in challenging process conditions.

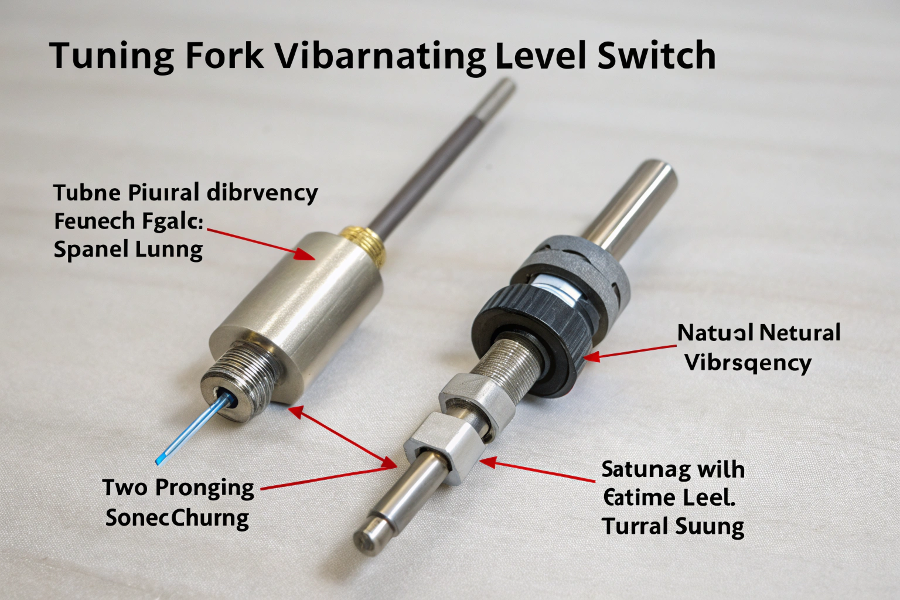

Tuning Fork Level Switch Overview

I’ve seen numerous applications where tuning fork switches outperform other technologies. Let me share my insights.

What is a Tuning Fork Level Switch?

Traditional level detection methods often struggle with buildup, foam, and turbulence, leading to false readings and system failures.

A tuning fork level switch consists of a two-pronged fork that vibrates at its natural frequency, detecting level changes when material contacts the fork and alters its vibration.

Tuning Fork Components and Operation

From my extensive experience:

Key Components

Main Elements

Component Function Importance Fork Tines Vibration sensing Primary detection Electronics Signal processing Measurement control Housing Protection Environmental safety Process Connection Installation System integration Design Features

- Self-cleaning capability

- Fail-safe operation

- Temperature compensation

- Diagnostic functions

Application Benefits

Operational Advantages

- Minimal maintenance

- No calibration needed

- High reliability

- Simple installation

Performance Features

- Independent of material properties

- Immune to buildup

- Vibration resistant

- Self-monitoring

These features make tuning forks highly versatile.

Are There Different Types of Tuning Forks?

Selecting the wrong tuning fork variant can lead to poor performance and reliability issues.

Tuning fork switches come in various designs optimized for liquids, solids, and different process conditions, with options for high temperature, high pressure, and corrosive applications.

Tuning Fork Variations

Based on my implementation experience:

Fork Variations

Application-Specific Types

Type Design Features Best For Standard Basic design General liquids Extended Longer tines Deep vessels Compact Short body Limited space High-temp Special materials Hot processes Material Options

- Stainless steel

- Alloy options

- Coated versions

- Special materials

Selection Criteria

Process Considerations

- Operating conditions

- Material properties

- Installation requirements

- Safety needs

Design Requirements

- Mounting options

- Output signals

- Certifications

- Documentation

These variations ensure optimal application matching.

What Are the Types of Level Switches?

Understanding available level switch technologies helps in making informed selection decisions.

Level switcheshttps://soaringinstrument.com/level-switch/ include various technologies such as float, tuning fork, capacitive, optical, and conductivity-based designs, each offering unique advantages for specific applications.

Level Switch Technology Comparison

Drawing from my technical knowledge:

Technology Overview

Common Technologies

Type Operating Principle Best Application Tuning Fork Vibration Universal use Float Buoyancy Simple liquids Capacitive Dielectric Interface detection Optical Light reflection Clean liquids Selection Factors

- Process conditions

- Material properties

- Reliability needs

- Maintenance requirements

Implementation Guide

Technology Selection

- Application requirements

- Environmental conditions

- Installation constraints

- Budget considerations

System Integration

- Control interface

- Power requirements

- Signal processing

- Alarm management

These options provide solutions for various applications.

How Does a Fork Level Switch Work?

Many users need to understand the operating principle to properly implement and troubleshoot fork switches.

Fork level switches operate by maintaining a constant vibration frequency in air and detecting changes when material contacts the fork, causing a frequency shift that triggers the switch.

Fork Level Switch Operation Principle

Based on my field experience:

Operating Principle

Basic Operation

Phase Action Result Normal Fork vibrates Base frequency Contact Material touches Frequency changes Detection Electronics sense Switch triggers Recovery Material leaves Returns to base Critical Parameters

- Vibration frequency

- Dampening effect

- Switch point

- Time delay

Performance Factors

Environmental Effects

- Temperature impact

- Pressure influence

- Coating effects

- Vibration resistance

Operational Considerations

- Installation position

- Flow effects

- Material buildup

- Maintenance access

These factors ensure reliable operation.

Conclusion

Tuning fork level switches provide reliable point level detection across diverse applications, offering maintenance-free operation and robust performance when properly selected and installed.