Field technicians often struggle with quick, accurate flow measurements across multiple locations without disrupting operations.

A handheld ultrasonic flow meter is a portable device that measures fluid flow non-invasively using ultrasonic technology, ideal for temporary measurements and system audits.

Handheld Ultrasonic Flow Meter

Let me share insights from my experience with portable flow measurement solutions.

What is a Portable Ultrasonic Flow Meter?

Many maintenance teams need flexible flow measurement solutions for various locations.

A portable ultrasonic flow meter is a battery-powered device with detachable transducers that can be quickly moved between measurement points for temporary flow monitoring.

From my field experience:

Key Features

Design Elements

Component Function Benefit Display unit Data visualization Easy reading Transducers Flow sensing Quick setup Battery Power supply Independence Memory Data logging Analysis Practical Applications

- Energy audits

- Leak detection

- System verification

- Maintenance checks

Operational Benefits

Usage Advantages

- Quick deployment

- No system modification

- Multiple site usage

- Cost-effective solution

Technical Capabilities

- Flow trending

- Data recording

- Energy calculation

- Performance validation

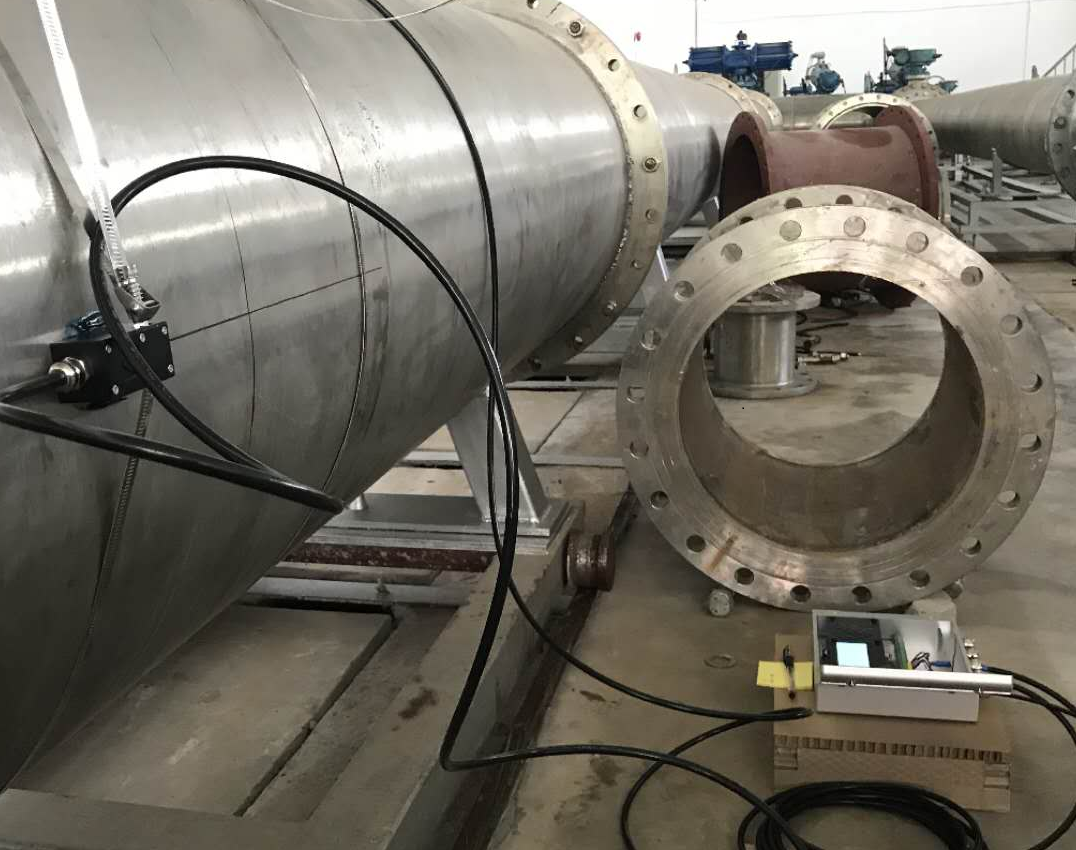

What is a Clamp-On Ultrasonic Flow Meter?

Engineers often need non-invasive flow measurement solutions for various applications.

A clamp-on ultrasonic flow meter uses external sensors attached to the pipe surface to measure flow rate without pipe modification or process interruption.

Clamp-on Installation Method

Based on my installation experience:

Installation Process

Setup Requirements

Step Action Purpose Surface prep Cleaning Signal quality Mounting Positioning Accuracy Coupling Gel application Signal transfer Validation Signal check Reliability Critical Considerations

- Pipe material

- Flow conditions

- Environmental factors

- Access requirements

Application Areas

Common Uses

- Process monitoring

- Energy measurement

- Flow verification

- Temporary studies

System Requirements

- Straight pipe run

- Surface condition

- Material compatibility

- Power availability

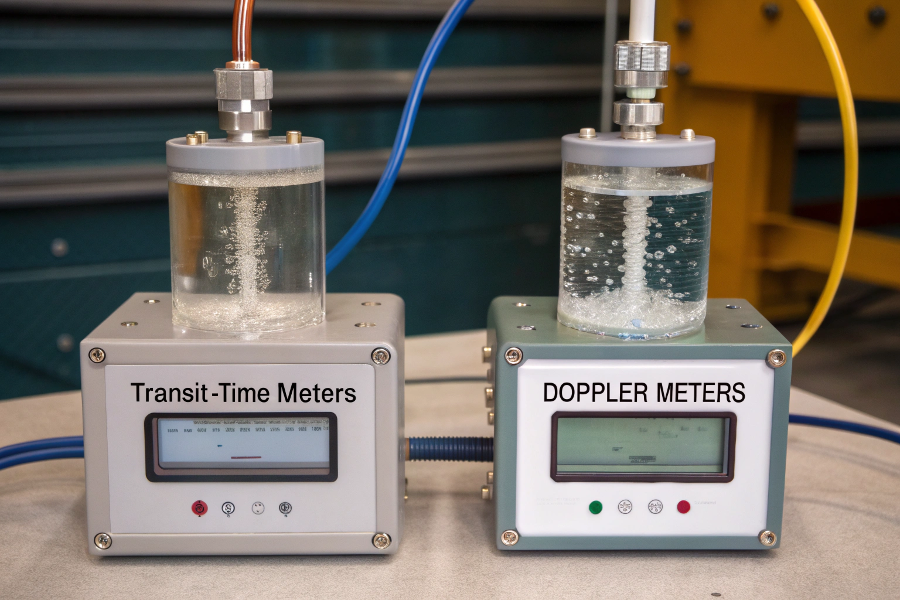

Which Two Types of Ultrasonic Flow Meters are Commonly in Use?

Users need to understand different measurement principles for proper application.

Transit-time and Doppler are the two main types, with transit-time used for clean fluids and Doppler for liquids containing particles.

Ultrasonic Measurement Types

Drawing from my technical expertise:

Transit-Time Technology

Operating Principles

Aspect Detail Application Signal path Direct transmission Clean fluids Measurement Time difference Precise flow Accuracy High precision Critical measurement Requirements Clean liquid Custody transfer Key Applications

- Water systems

- Oil transfer

- Chemical processes

- HVAC systems

Doppler Technology

Measurement Method

Feature Description Usage Principle Frequency shift Particle reflection Requirements Suspended solids Dirty fluids Performance Flow indication Process monitoring Application Slurries Wastewater Typical Uses

- Wastewater treatment

- Mining operations

- Pulp and paper

- Chemical processing

What is the Difference Between Inline and Clamp-On Ultrasonic Flow Meters?

Plant engineers must choose between permanent and temporary installation options.

Inline meters require pipe modification and direct fluid contact, while clamp-on meters mount externally without process interruption.

Installation Type Comparison

Based on my system design experience:

Installation Methods

Inline Installation

Factor Requirement Impact Pipe work Cutting required System downtime Connection Direct contact Higher accuracy Maintenance Internal access More complex Cost Higher initial Better long-term Clamp-On Installation

- Non-invasive mounting

- Quick deployment

- Easy maintenance

- Lower initial cost

Performance Comparison

Accuracy Considerations

- Installation effects

- Calibration stability

- Long-term reliability

- Environmental factors

Application Factors

- Process requirements

- Installation constraints

- Maintenance needs

- Budget limitations

Conclusion

Handheld ultrasonic flow meters offer versatile, non-invasive flow measurement solutions, combining portability with reliable performance for temporary measurement needs across various applications.