Factory engineers often struggle finding flow measurement solutions for steam and aggressive gases. Vortex flow meters solve these challenges with their unique non-contact measurement principle.

Vortex flow meters optimally measure steam, gases, and low-viscosity liquids in 5 key applications: 1) Steam energy monitoring (80% of industrial use), 2) Compressed air systems, 3) Natural gas flow, 4) Chemical processes, and 5) HVAC refrigerant circuits. Their no-moving-part design ensures 10+ year lifespan in these demanding services.

Vortex Meter in Steam Service

Understanding proper vortex meter applications prevents costly measurement errors while maximizing equipment value.

What Is the Application of Vortex Flow Meter?

Seven industries where vortex technology dominates:

Industry-Specific Application Table

| Industry | Typical Application | Why Vortex Works |

|---|---|---|

| Power | Steam turbine feedwater | Handles 400°C superheated steam |

| Chemical | Solvent gas transfer | Resists corrosive media |

| Oil & Gas | Fuel gas measurement | No lubrication needed |

| Food | Cooking steam control | CIP-compatible designs |

| Pharma | Clean steam monitoring | Sanitary configurations |

| HVAC | Chilled water flow | Low maintenance requirement |

| Mining | Compressed air | Vibration tolerant |

Critical Selection Factors

- Pipe Size Compatibility – Best for DN15 to DN300 lines

- Process Medium – Steam, air, gas, clean liquids

- Temperature Range – -40°C to 400°C capability

- Pressure Rating – Up to ANSI 2500 class

- Accuracy Needs – ±1% of rate typical

Cross-Industry Usage

Emerging Applications

- Carbon dioxide flow monitoring

- Cryogenic gas measurement

- Thermal oil systems

- Biogas production

- Semiconductor gas delivery

What Are the Applications of Vortex?

Five fluid-specific measurement scenarios:

Fluid Type Performance Comparison

| Fluid | Measurement Benefit | Special Considerations |

|---|---|---|

| Saturated Steam | No pressure compensation needed | Requires dryer installation |

| Compressed Air | No moving parts to wear | Filter upstream essential |

| Natural Gas | Bidirectional measurement | Needs temperature/pressure comp |

| Chlorine Gas | All-metal construction | Special material requirements |

| Hot Oil | High temp capability | Cooling jacket sometimes needed |

Installation Guidelines

- Orientation – Horizontal preferred for gases

- Flow Profile – 15D upstream straight pipe

- Vibration – Isolate from pumps/compressors

- Accessories – Install condensate pots for steam

- Calibration – Field verification possible

Fluid-Specific Solutions

Avoid These Fluids

- Slurries & abrasive media

- High viscosity liquids (>30 cP)

- Low conductivity liquids

- Sticky or coating fluids

- Pulsating flow conditions

What Are the Applications of Flow Meter?

Four measurement purposes where vortex excels:

Measurement Objective Matrix

| Purpose | Vortex Suitability | Alternative Technologies |

|---|---|---|

| Process Control | Excellent for steam/gas | Orifice plates need more maintenance |

| Energy Monitoring | Cost-effective solution | Thermal mass for lower flows |

| Batching Operations | Good for clean liquids | Positive displacement better accuracy |

| Safety Shutdowns | Reliable performance | Redundant sensors recommended |

Economic Applications

- Steam Trap Monitoring – Detects failed traps

- Boiler Efficiency – Tracks steam production

- Compressed Air Audit – Finds system leaks

- Cogeneration Plants – Measures gas/steam flows

- Heat Exchangers – Calculates energy transfer

Functional Applications

Future Application Trends

- Smart factory integration

- Predictive maintenance data

- Carbon emission tracking

- IIoT-enabled devices

- Multi-parameter measurement

When to Use a Vortex Flowmeter?

Six ideal selection scenarios:

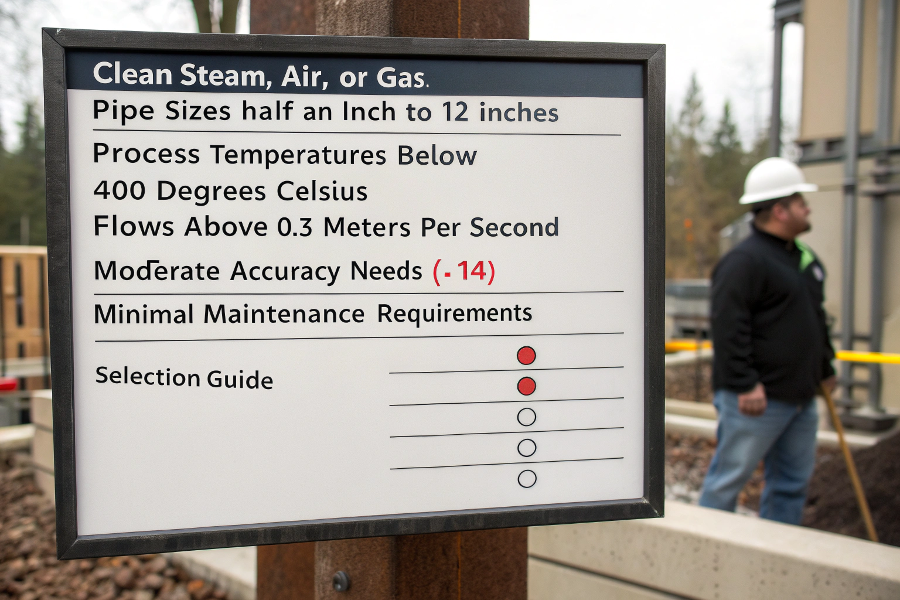

Decision Checklist

✓ Measuring clean steam, air or gas

✓ Pipe sizes between ½" to 12"

✓ Process temperatures <400°C

✓ Flows above 0.3 m/s velocity

✓ Moderate accuracy needs (±1%)

✓ Minimal maintenance desired

| Comparative Technology Guide | Condition | Choose Vortex Over… |

|---|---|---|

| Steam service | Orifice plates | |

| Compressed air | Turbine meters | |

| Chemical gases | Coriolis (cost) | |

| Thermal fluids | DP transmitters | |

| Large pipe gas | Ultrasonic |

Technology Selection

Installation Timing Tips

- During plant turnarounds

- When replacing failed meters

- New energy monitoring projects

- Process optimization initiatives

- Safety system upgrades

- Automation conversions

Conclusion

Vortex flow meters deliver optimal performance in steam, compressed air, and industrial gas applications where their rugged, no-moving-part design provides reliable measurements with minimal maintenance. Their economic advantages become particularly apparent in mid-size pipe applications (DN15-DN300) handling clean fluids with sufficient flow velocity. While not universal solutions, vortex meters outperform competing technologies in their