Poor acoustic coupling can lead to inaccurate readings and system failures, causing significant process control issues and revenue loss.

Ultrasonic coupling gel is a specialized acoustic couplant that ensures efficient sound transmission between ultrasonic transducers and pipe surfaces, typically costing $10-50 per tube.

Ultrasonic Coupling Gel Application

Ultrasonic Coupling Gel Application

I’ve seen many flow measurement failures due to improper coupling gel selection and application. Let me share what I’ve learned.

What is Ultrasonic Coupling Gel?

Misunderstanding the role of coupling gel can result in poor signal transmission and unreliable measurements.

Ultrasonic coupling gel is a viscous substance that eliminates air gaps between transducers and pipe surfaces, ensuring optimal ultrasonic wave transmission.

Coupling Gel Composition

From my technical experience:

Gel Characteristics

Key Properties

Property Importance Typical Range Viscosity1 Critical 30,000-100,000 cP Acoustic Impedance High 1.5-1.8 MRayl Temperature Stability Important -20°C to 120°C Corrosion Resistance2 Essential pH 6-8 Material Composition

- Water-based solutions

- Glycerin compounds

- Propylene glycol

- Thickening agents

Application Requirements

Usage Guidelines

- Surface preparation

- Application thickness

- Coverage area

- Reapplication intervals

Storage Conditions

- Temperature limits

- Container sealing

- Shelf life

- Contamination prevention

What Gel is Used in Ultrasonic Testing?

Using the wrong type of gel can compromise measurement accuracy and damage equipment.

Professional ultrasonic testing gels typically contain glycerin or propylene glycol bases with specific acoustic impedance matching properties.

Different Types of Ultrasonic Gels

Based on my product knowledge:

Common Gel Types

Product Categories

Type Application Temperature Range Standard General Use 0°C to 80°C High Temp Industrial -20°C to 120°C Non-Toxic Food Grade 0°C to 60°C Extended Life Long-term -10°C to 100°C Selection Criteria

- Operating temperature

- Environmental conditions

- Application duration

- Industry requirements

Performance Factors

Quality Indicators

- Acoustic efficiency

- Temperature stability

- Corrosion resistance

- Ease of removal

Certification Requirements

- Industry standards

- Safety compliance

- Material compatibility

- Environmental regulations

What is the Coupling Gel Used For?

Not understanding the purpose of coupling gel can lead to improper application and system failure.

Coupling gel eliminates air gaps between transducers and pipe surfaces, maximizing ultrasonic signal transmission and ensuring accurate flow measurements.

Drawing from my installation experience:

Application Purposes

Primary Functions

Function Benefit Impact Signal Transmission Better Accuracy Critical Air Gap Elimination Reduced Noise Essential Surface Protection Extended Life Important Temperature Buffer Stability Beneficial Performance Benefits

- Improved signal strength

- Better measurement stability

- Reduced maintenance

- Extended sensor life

Best Practices

Application Methods

- Surface cleaning

- Proper amount

- Even distribution

- Regular inspection

Maintenance Requirements

- Periodic checks

- Reapplication timing

- Cleaning procedures

- Quality verification

What Are the Disadvantages of Clamp-on Ultrasonic Flow Meter?

Ignoring potential limitations of clamp-on meters can result in unexpected measurement issues.

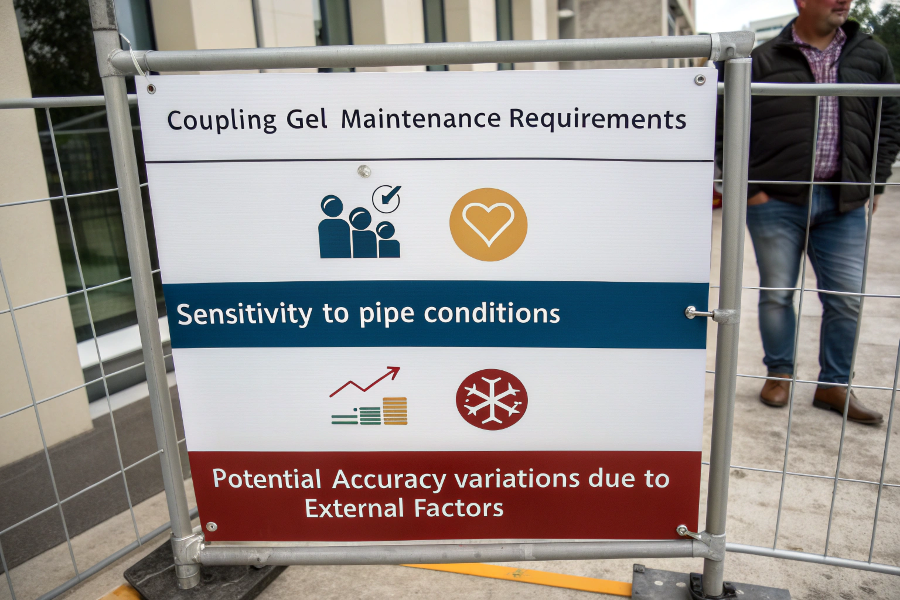

Key disadvantages include coupling gel maintenance requirements, sensitivity to pipe conditions, and potential accuracy variations due to external factors.

Common Issues with Clamp-on Meters

From my troubleshooting experience:

Common Challenges

Technical Limitations

Issue Impact Solution Coupling Maintenance Signal Quality Regular Checks Surface Condition Accuracy Proper Preparation Environmental Effects Reliability Protection Measures Installation Quality Performance Expert Setup Operational Concerns

- Temperature variations

- Vibration effects

- Weather exposure

- Access limitations

Mitigation Strategies

Installation Solutions

- Proper site selection

- Surface preparation

- Environmental protection

- Regular maintenance

Performance Optimization

- Quality coupling gel

- Correct application

- Monitoring program

- Preventive maintenance

Conclusion

Using the right ultrasonic coupling gel and proper application techniques is crucial for accurate flow measurement, making it an essential component of successful clamp-on flow meter installations.