I often encounter confusion about how differential pressure transmitters actually measure flow.

A DP transmitter works by measuring the pressure difference between two points in a flow system, converting this differential pressure into an electronic signal for flow rate calculation.

DP Transmitter Basic Components

Let me break down the complexities of DP measurement technology.

How Does a DP Flow Transmitter Work?

Many users struggle to understand the relationship between pressure difference and flow measurement.

DP flow transmitters use pressure sensors on both sides of a flow restriction, measuring the pressure drop to calculate flow rate using Bernoulli’s principle.

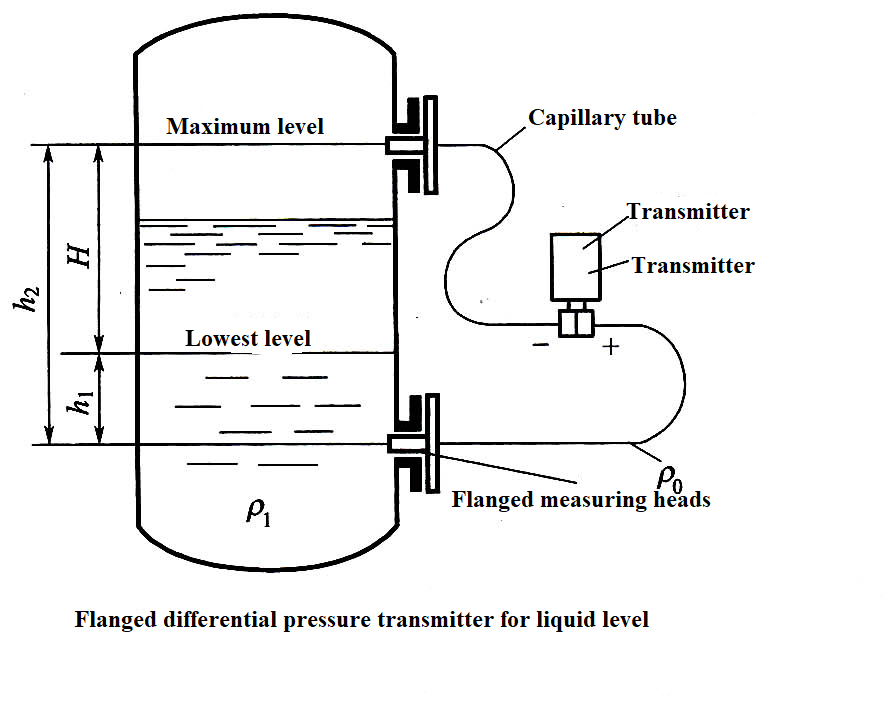

DP Flow Measurement Setup

From my experience installing and maintaining DP transmitters:

Core Components

Physical Elements

Component Function Critical Aspects Primary element Flow restriction Precise geometry Sensing diaphragm Pressure detection Material integrity Impulse lines Pressure transmission Proper installation Electronics Signal processing Calibration accuracy System Requirements

- Proper mounting

- Correct orientation

- Clean impulse lines

- Regular maintenance

Operating Process

Measurement Steps

- Pressure detection

- Signal conversion

- Flow calculation

- Output generation

Critical Factors

- Temperature effects

- Static pressure

- Installation quality

- Calibration accuracy

What is the Principle of DP?

Understanding differential pressure is fundamental to flow measurement.

Differential pressure is the difference in pressure between two points, created by flow restriction and directly related to flow velocity through Bernoulli’s equation.

DP Principle Illustration

DP Principle Illustration

Based on my technical expertise:

Physical Principles

Key Concepts

Principle Description Application Bernoulli’s law Flow-pressure relationship Flow calculation Conservation of mass Flow continuity Measurement basis Energy conversion Pressure-velocity relation Flow determination Square root relationship Flow-DP correlation Signal processing Mathematical Relationships

- Flow equations

- Pressure correlations

- Velocity calculations

- Density effects

Practical Applications

Implementation Considerations

- Primary device selection

- Installation requirements

- Calibration needs

- Maintenance schedule

Performance Factors

- Accuracy requirements

- Rangeability needs

- Environmental conditions

- Process constraints

What is the Working Principle of Transmitter?

The transmitter’s role in converting physical measurements to useful signals is often misunderstood.

Transmitters convert physical pressure differences into standardized electronic signals through sensor technology and signal processing.

Transmitter Operation Diagram

Drawing from our manufacturing experience:

Signal Processing

Conversion Steps

Stage Process Output Sensing Physical detection Raw signal Conditioning Signal processing Clean signal Conversion A/D transformation Digital data Output Signal generation 4-20mA/Digital Processing Elements

- Sensor technology

- Electronics design

- Software algorithms

- Output protocols

Quality Features

Performance Aspects

- Accuracy specifications

- Response time

- Stability factors

- Environmental resistance

Maintenance Requirements

- Calibration procedures

- Diagnostic capabilities

- Service intervals

- Troubleshooting methods

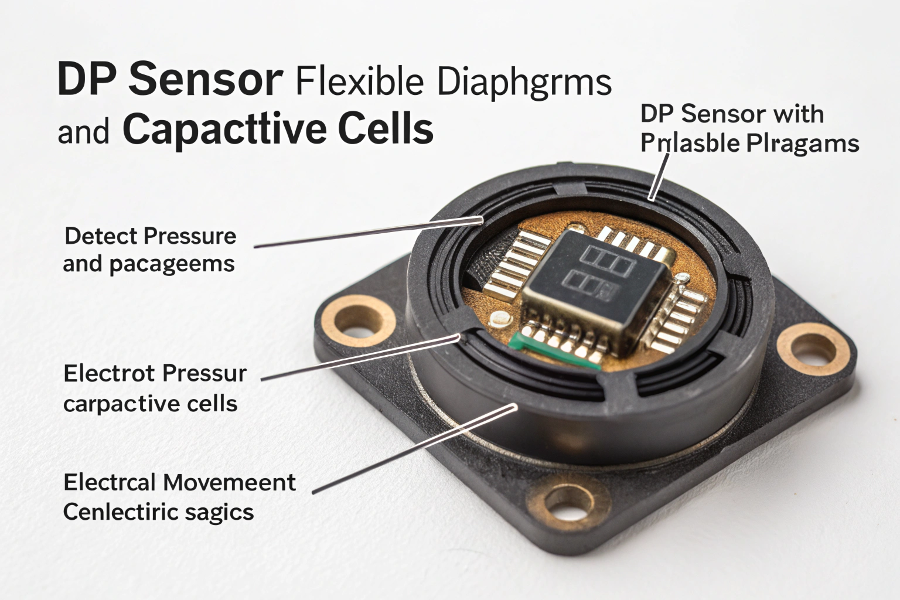

How Does a DP Sensor Work?

The sensing element is the heart of any DP transmitter.

DP sensors use flexible diaphragms or capacitive cells to detect pressure differences, converting mechanical movement into electrical signals.

DP Sensor Construction Details

Based on our sensor design experience:

Sensor Technology

Design Elements

Component Purpose Design Considerations Diaphragm Pressure sensing Material selection Fill fluid Force transmission Temperature stability Electronics Signal generation Environmental protection Housing Protection Durability Operating Principles

- Force balance

- Displacement detection

- Signal generation

- Temperature compensation

Performance Factors

Critical Parameters

- Accuracy rating

- Response time

- Stability level

- Environmental limits

Quality Aspects

- Material selection

- Manufacturing precision

- Testing procedures

- Certification requirements

Conclusion

Understanding DP transmitter principles is essential for proper selection, installation, and maintenance, ensuring accurate and reliable flow measurement in industrial applications.