Many industrial users struggle with meeting regulatory requirements due to incorrect flow meter calibration practices.

Flow meter calibration standards primarily follow ISO 17025, ISO/IEC 9001, and NIST guidelines, requiring traceability, documented procedures, and specified accuracy limits.

Flow Meter Calibration Standards Overview

Let me share my experience in implementing calibration standards across various industries.

What Is The Standard For Calibration Of Flow Meter?

Improper calibration procedures can lead to significant measurement errors and regulatory non-compliance.

Flow meter calibration standards require maintaining measurement uncertainty within ±0.2% to ±0.5%, following documented procedures, and ensuring traceability to national standards.

Flow Meter Calibration Process

Based on my calibration experience:

Calibration Requirements

Key Standards Components

Component Requirement Purpose Frequency Traceability1 National Standards Accuracy Assurance Each Calibration Documentation Complete Records Audit Trail Continuous Uncertainty Defined Limits Quality Control Each Test Environment Controlled Conditions Reliability Continuous Implementation Steps

- Standard operating procedures

- Calibration intervals

- Error analysis

- Uncertainty calculations

Quality Control Measures

Process Verification

- Equipment validation

- Personnel qualification

- Method verification

- Data analysis

Documentation Requirements

- Calibration certificates

- Uncertainty statements

- Traceability records

- Maintenance logs

What Is The ISO Standard For Calibration?

Understanding ISO calibration standards is crucial for maintaining measurement accuracy.

ISO 17025 is the primary standard for calibration laboratories, while ISO 9001 provides quality management system requirements for calibration processes.

ISO Calibration Standards

From my ISO implementation experience:

ISO Requirements

Standard Components

Standard Focus Area Requirements Application ISO 170252 Technical Lab Competence Calibration Labs ISO 90013 Quality Management System All Organizations ISO 10012 Measurement System Management Manufacturing ISO 4006 Terminology Definitions All Users Implementation Guidelines

- Quality manual development

- Procedure documentation

- Staff training

- Record keeping

Compliance Process

Documentation Requirements

- Quality policies

- Work instructions

- Calibration procedures

- Training records

Quality Assurance

- Internal audits

- Management reviews

- Corrective actions

- Continuous improvement

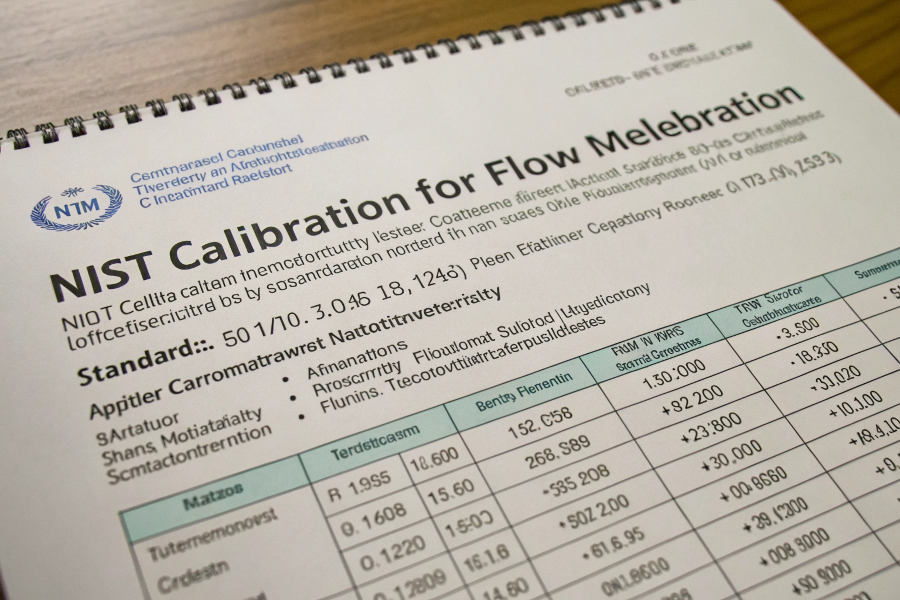

What Is The NIST Standard For Calibration?

NIST standards ensure measurement accuracy and traceability in the US market.

NIST calibration standards provide reference measurements, uncertainty guidelines, and traceability requirements for flow meter calibration in the United States.

NIST Calibration Standards

Drawing from my NIST compliance experience:

NIST Requirements

Standard Elements

Element Description Purpose Implementation Traceability Chain of Comparisons Accuracy Link Documentation Uncertainty Error Analysis Accuracy Limits Calculations Methods Standard Procedures Consistency Training Documentation Complete Records Verification Maintenance Implementation Process

- Reference standards

- Calibration procedures

- Uncertainty analysis

- Quality control

Compliance Methods

Technical Requirements

- Equipment specifications

- Environmental conditions

- Personnel qualifications

- Method validation

Documentation Needs

- Calibration certificates

- Uncertainty budgets

- Traceability records

- Quality manual

What Is The ISO Standard For Flow Measurement?

Flow measurement standards ensure consistency and reliability across industries.

ISO standards for flow measurement include ISO 5167 for differential pressure devices, ISO 4185 for liquid flow calibration, and ISO 9951 for gas meters.

Flow Measurement Standards

Based on my implementation experience:

ISO Flow Standards

Standard Categories

Standard Application Requirements Key Focus ISO 5167 Differential Pressure Installation Accuracy ISO 4185 Liquid Flow Calibration Methods ISO 9951 Gas Flow Performance Safety ISO 6817 Electromagnetic Operation Reliability Implementation Guidelines

- Installation requirements

- Operating conditions

- Maintenance procedures

- Performance verification

Application Process

Technical Requirements

- Flow conditions

- Installation details

- Measurement methods

- Performance criteria

Quality Assurance

- Regular testing

- Performance monitoring

- Documentation review

- Corrective actions

Conclusion

Successful flow meter calibration requires adherence to relevant standards (ISO, NIST), proper documentation, regular maintenance, and continuous monitoring to ensure measurement accuracy and reliability.