Many industries struggle with finding reliable, non-invasive flow measurement solutions that won’t disrupt their processes.

Ultrasonic flow meters measure fluid flow rates in pipes using sound waves, providing accurate, non-intrusive measurement without direct contact with the fluid.

Ultrasonic Flow Meter Basic Function

Let me share insights from my experience with ultrasonic flow meters to help you understand their purpose and capabilities.

What Is The Function Of Ultrasonic Flow Meter?

Finding a flow measurement solution that combines accuracy with easy installation and maintenance can be challenging.

Ultrasonic flow meters function by sending sound waves through pipe walls to measure fluid velocity, calculating flow rates without interrupting the process or requiring pipe modifications.

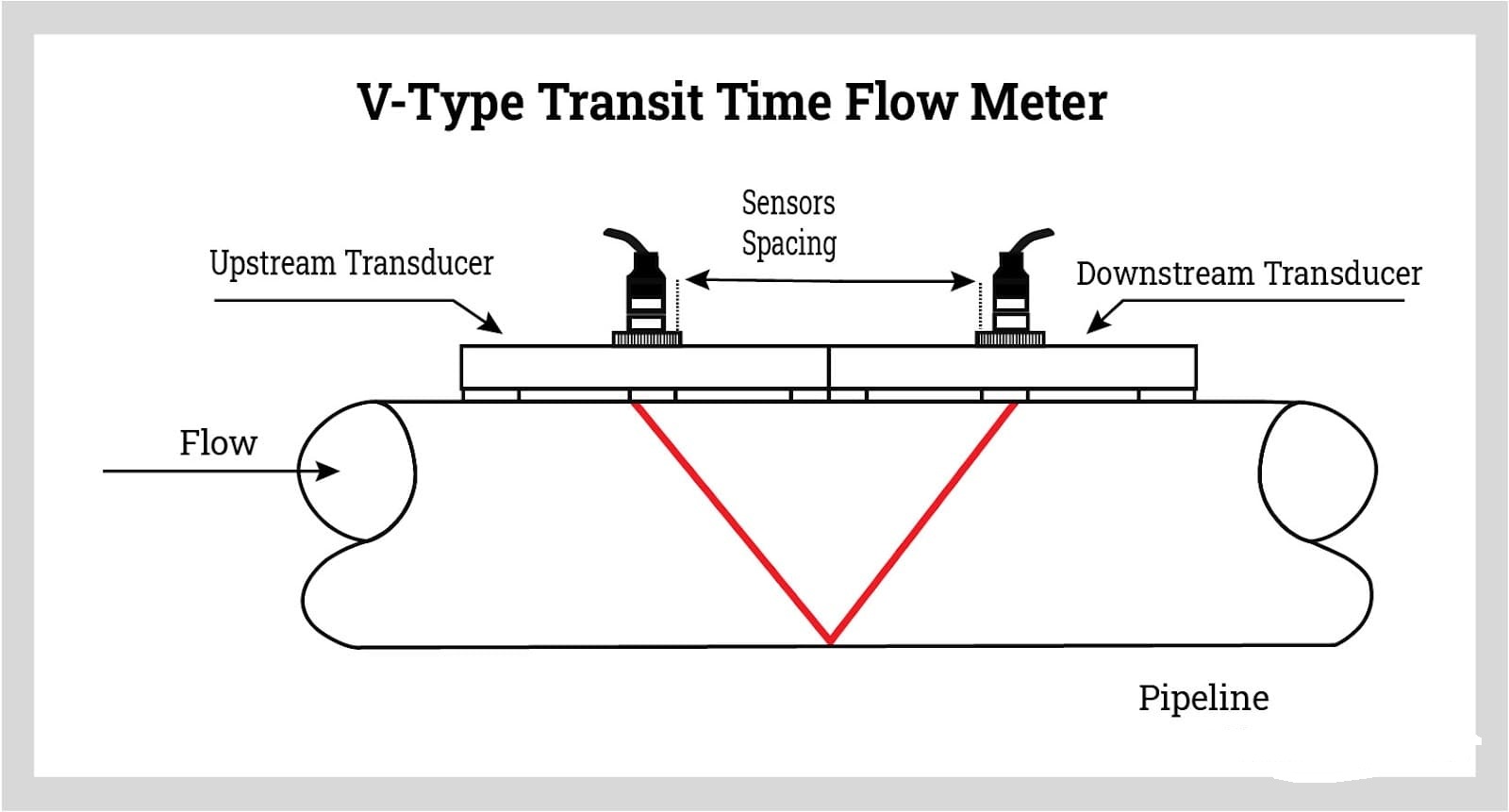

Ultrasonic Flow Meter Working Process

From my implementation experience:

Core Functions

-

Measurement Capabilities

Function Method Benefit Application Flow Rate Sound waves Non-invasive Process control Volume Time integration Totalization Billing Velocity Transit time Real-time data Monitoring Direction Signal analysis Bi-directional System analysis -

Signal Processing

- Waveform analysis

- Noise filtering

- Temperature compensation

- Flow calculations

Output Features

-

Data Management

- Digital display

- Analog outputs

- Communication protocols

- Data logging

-

System Integration

- Control systems

- Remote monitoring

- Alarm functions

- Reporting tools

What Is The Purpose Of A Flow Meter?

Industries often face challenges in accurately monitoring and controlling fluid movement in their processes.

Flow meters serve to measure, monitor, and control fluid flow rates in pipes, helping optimize processes, ensure product quality, and manage resource consumption.

Flow Meter Applications Overview

Based on my field experience:

Primary Purposes

-

Process Applications

Purpose Benefit Industry Impact Control Process optimization Manufacturing Quality Billing Revenue accuracy Utilities Financial Safety System protection Chemical Risk reduction Analysis Performance data Research Development -

Operational Benefits

- Resource management

- Cost control

- Quality assurance

- Compliance monitoring

Implementation Goals

-

System Requirements

- Accuracy needs

- Operating conditions

- Installation constraints

- Budget considerations

-

Performance Metrics

- Measurement accuracy

- System reliability

- Maintenance needs

- Cost effectiveness

How To Use An Ultrasonic Flow Meter?

Proper installation and operation are crucial for achieving accurate flow measurements.

To use an ultrasonic flow meter, select appropriate mounting locations, prepare pipe surfaces, install transducers correctly, and configure the meter settings for your specific application.

Ultrasonic Flow Meter Installation Guide

Drawing from my expertise:

Installation Steps

-

Setup Process

Step Action Critical Factors Verification Site prep Clean surface Pipe condition Visual check Mounting Position sensors Alignment Signal strength Config Enter parameters Accuracy Test readings Testing Validate output Performance Data analysis -

Best Practices

- Follow guidelines

- Use proper tools

- Document settings

- Regular maintenance

Operation Guide

-

Daily Use

- Monitor readings

- Check signals

- Record data

- Watch for alerts

-

Maintenance Tasks

- Clean sensors

- Check alignment

- Verify settings

- Update records

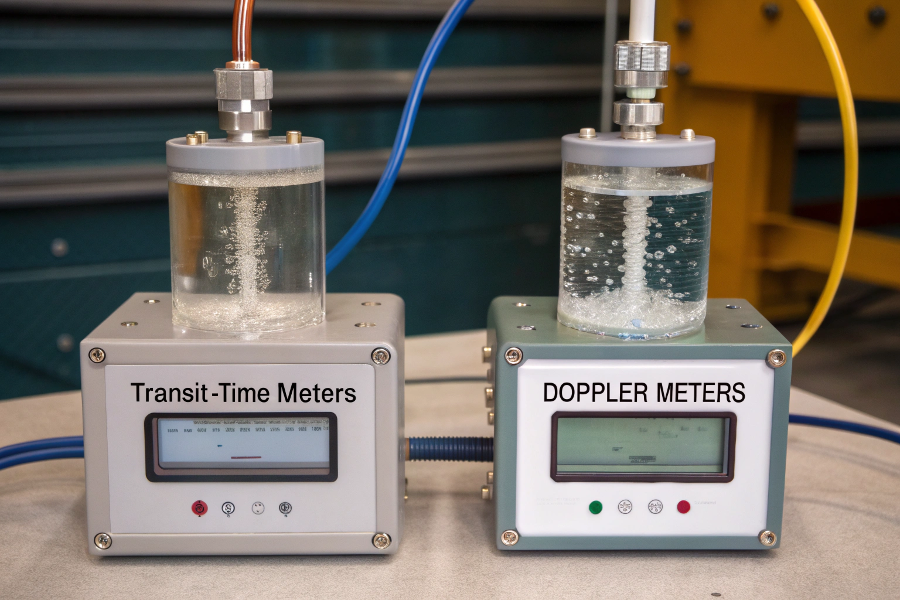

What Is The Principle Of Ultrasonic Doppler Flow Meter?

Understanding the Doppler principle helps in proper application and troubleshooting of flow measurements.

Doppler flow meters measure flow by detecting frequency shifts in ultrasonic signals reflected off particles or bubbles in the fluid stream.

Doppler Flow Meter Operating Principle

Based on my experience:

Operating Principles

-

Technical Details

Component Function Requirement Impact Transducer Signal emission Clean contact Accuracy Particles Signal reflection Minimum content Detection Processor Frequency analysis Signal quality Results Display Data output Configuration Usability -

Signal Processing

- Frequency detection

- Velocity calculation

- Flow computation

- Data conversion

Application Guidelines

-

Requirements

- Particle content

- Flow conditions

- Pipe characteristics

- Installation space

-

Performance Factors

- Signal strength

- Particle distribution

- Flow profile

- Environmental conditions

Conclusion

Ultrasonic flow meters serve as versatile, non-invasive flow measurement tools, offering accurate readings and easy installation when properly implemented according to specific application requirements.