Struggling to select the right flow meter? With over 15 types available, each with unique strengths, choosing incorrectly can lead to costly measurement errors and maintenance headaches.

The most commonly used flow meter globally is the electromagnetic (mag) flow meter, representing 27% of industrial installations according to Flow Research. Its popularity stems from no moving parts (low maintenance), high accuracy (±0.5%), and ability to handle dirty liquids like wastewater, slurries, and corrosive chemicals.

Electromagnetic Flow Meter

Let’s examine why certain flow meters dominate specific applications.

What Is the Most Common Type of Flow Meter?

Different industries have their workhorse flow technologies.

Top 5 flow meter types by market share:

1) Electromagnetic (27%),

2) Differential pressure (21%),

3) Ultrasonic (18%),

4) Coriolis (12%),

5) Turbine (9%).

Selection depends on fluid type – mag meters dominate water/wastewater, while Coriolis leads in oil/gas custody transfer due to mass flow measurement.

Industry adoption patterns reveal clear preferences:

Flow Meter Usage by Industry

| Industry | Preferred Type | Reason | Market Share |

|---|---|---|---|

| Water/Wastewater | Electromagnetic | Handles dirty liquids | 65% |

| Oil & Gas | Coriolis | Mass flow measurement | 42% |

| Chemicals | Magnetic/Coriolis | Corrosion resistance | 38% |

| Power Generation | Differential Pressure | Steam measurement | 55% |

| Food & Beverage | Sanitary Turbine | CIP/SIP compatibility | 33% |

What Is the Most Common Measure of Flow?

Flow measurement units vary by application.

Volumetric flow (m³/h, gpm) is most common in process industries (used in 78% of applications). Mass flow (kg/h, lb/min) dominates custody transfer (oil/gas). Velocity (m/s) is primarily used in water distribution. Energy flow (BTU/hr) is standard for steam systems.

Unit selection depends on critical parameters:

Flow Measurement Unit Guide

| Measurement Need | Preferred Unit | Typical Accuracy | Best Meter Type |

|---|---|---|---|

| Billing | m³ (volume) | ±1% | Positive Displacement |

| Process Control | kg (mass) | ±0.5% | Coriolis |

| Chemical Dosing | l/min (volume) | ±0.2% | Micro Coriolis |

| Water Distribution | m/s (velocity) | ±2% | Ultrasonic |

| Steam Systems | kJ/kg (energy) | ±2% | DP with density compensation |

What Is the Most Commonly Used Flow Measuring Device in Industry?

Plant requirements differ from laboratory specs.

In industrial settings, clamp-on ultrasonic flow meters are the most commonly installed due to non-intrusive retrofitting (60% of new installations). However, electromagnetic meters still lead in total installed base (1.2 million units globally) because of 20+ year lifespans in water applications.

Ultrasonic Flow Meter

Installation trends show clear patterns:

Industrial Flow Meter Adoption Factors

| Factor | Top Choice | Reason | Installation % |

|---|---|---|---|

| New Installations | Ultrasonic | No pipe modification | 42% |

| Retrofit Projects | Clamp-on Ultrasonic | No process shutdown | 38% |

| High-Accuracy | Coriolis | ±0.1% capability | 15% |

| Low Maintenance | Magnetic | No moving parts | 27% |

| High Temperature | DP Flow | Handles 400°C+ steam | 18% |

Which Type of Flowmeter Is Most Accurate?

Accuracy claims require context – lab vs field conditions differ drastically.

Laboratory: Coriolis flow meters achieve ±0.05% under ideal conditions. Real-world: Magnetic and ultrasonic meters typically deliver ±0.5-1% in industrial settings. Accuracy depends on proper installation – a ±0.1% Coriolis meter improperly installed may only achieve ±2% accuracy.

Real-world performance varies significantly:

Flow Meter Accuracy in Practice

| Meter Type | Lab Accuracy | Field Accuracy | Conditions Required |

|---|---|---|---|

| Coriolis | ±0.05% | ±0.1-0.5% | No vibration, single-phase |

| Magnetic | ±0.2% | ±0.5-1% | Full pipe, conductive fluid |

| Ultrasonic (Transit-time) | ±0.5% | ±1-2% | Clean liquid, no bubbles |

| Turbine | ±0.25% | ±0.5-2% | No particulates, stable flow |

| DP Flow | ±1% | ±2-5% | Proper pressure tap location |

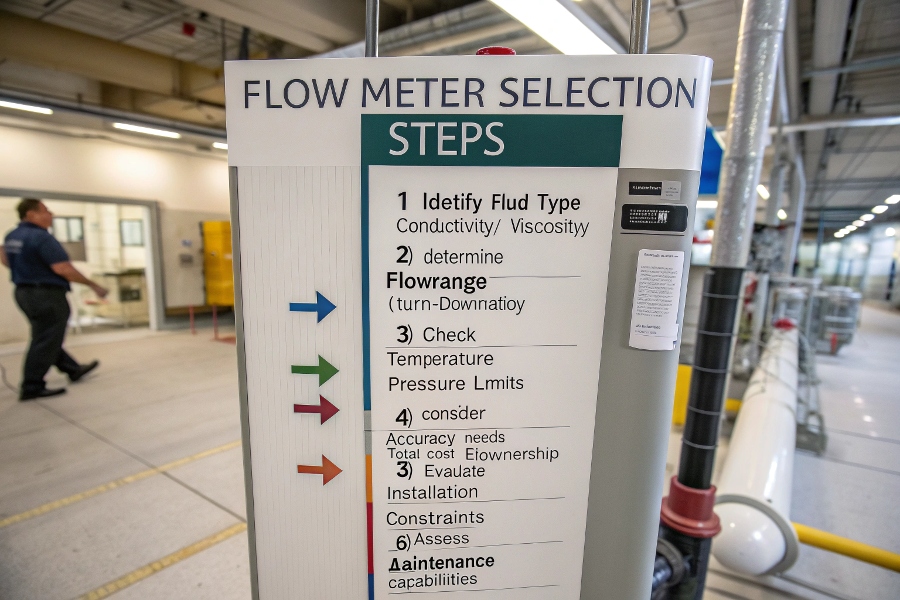

Flow Meter Selection Methodology

Choosing the right meter requires systematic evaluation.

7-step selection process:

1) Identify fluid type (conductivity/viscosity),

2) Determine flow range (turn-down ratio),

3) Check temperature/pressure limits,

4) Consider accuracy needs,

5) Evaluate installation constraints,

6) Assess maintenance capabilities,

7) Calculate total cost of ownership.

Missing any step causes 80% of flow meter failures.

Flow Meter Selection Steps

Decision matrix for common fluids:

Flow Meter Selection Guide by Fluid

| Fluid | Best Type | Why? | Avoid |

|---|---|---|---|

| Clean Water | Magnetic | ±0.5%, no moving parts | Turbine (fouling) |

| Crude Oil | Coriolis | Mass flow measurement | Magnetic (non-conductive) |

| Compressed Air | Thermal Mass | No pressure drop | DP Flow (expensive) |

| Slurries | Slurry Magnetic | Handles abrasives | Turbine (clogging) |

| High-Purity Chemicals | Coriolis | No contamination risk | Any mechanical type |

Total Cost of Ownership Analysis

Smart purchasing looks beyond sticker prices.

5-year costs:

1) Mag meters ($8-15K total),

2) Ultrasonic ($12-20K),

3) Coriolis ($25-50K).

Despite higher initial costs, Coriolis meters often prove cheapest long-term due to reduced calibration needs (1/3 the cost of DP flow maintenance).

5-Year Cost Breakdown

Component cost breakdown:

Flow Meter Cost Components (5 Years)

| Cost Factor | Magnetic | Ultrasonic | Coriolis |

|---|---|---|---|

| Purchase | $5-10K | $8-15K | $15-30K |

| Installation | $1-3K | $0.5-2K | $2-5K |

| Calibration | $1K/year | $800/year | $2K/2 years |

| Repairs | $500/year | $1K/year | $3K/3 years |

| Total | $8-15K | $12-20K | $25-50K |

Conclusion

While electromagnetic flow meters remain the most commonly used globally, the "best" flow meter depends entirely on your specific application requirements. Consider fluid properties, accuracy needs, installation constraints, and total ownership costs. Proper selection ensures reliable measurements with minimal maintenance – crucial for both process efficiency and bottom-line results.