Understanding flow measurement is crucial for industrial processes, but traditional methods can be invasive and maintenance-intensive.

An ultrasonic flow meter uses sound waves to measure liquid flow rates non-invasively, providing accurate measurements without disrupting the flow or requiring pipe modifications.

Ultrasonic Flow Meter Function Diagram

Let me explain how these devices work based on my extensive experience with flow measurement technology.

What Does An Ultrasonic Flow Meter Do?

Many industries struggle with accurate flow measurement while maintaining process integrity.

Ultrasonic flow meters measure liquid flow rates by sending sound waves through pipe walls, calculating flow velocity based on how these waves are affected by the moving fluid.

Ultrasonic Measurement Process

From my technical expertise:

Core Functions

-

Measurement Principles

Function Method Application Output Flow velocity Transit time Clean liquids Speed data Volume calculation Area × velocity Flow rate Volume total Signal analysis Wave processing Data validation Quality check Data reporting Digital conversion Monitoring Flow reports -

Operating Modes

- Continuous monitoring

- Batch measurement

- Totalizing

- Data logging

Key Features

-

Measurement Capabilities

- Real-time flow rate

- Total volume

- Flow direction

- Fluid properties

-

System Functions

- Self-diagnostics

- Error detection

- Data storage

- Communication protocols

What Are The Advantages Of Ultrasonic Flowmeter?

Traditional flow meters often present installation and maintenance challenges that impact operational efficiency.

Ultrasonic flowmeters offer non-intrusive installation, zero pressure drop, no moving parts, and high accuracy, making them ideal for many industrial applications.

%(percentage)ultrasonic-advantages

Based on my field experience:

Key Benefits

-

Technical Advantages Feature Benefit Impact Value Non-intrusive Easy installation No process interruption Cost savings No moving parts Low maintenance Reduced downtime Reliability Bi-directional Flow direction detection Process flexibility Versatility Digital output Advanced analytics Better control Efficiency -

Operational Benefits

- Zero pressure drop

- Wide turndown ratio

- High accuracy

- Long-term stability

Application Benefits

-

Industry Applications

- Water distribution

- Chemical processing

- Energy management

- Custody transfer

-

Process Advantages

- Clean installation

- Easy verification

- Remote monitoring

- Low ownership cost

How Do You Calibrate An Ultrasonic Flow Meter?

Proper calibration ensures measurement accuracy, but many users find the process complex.

Calibrating an ultrasonic flow meter involves verifying zero point, checking signal strength, validating measurements against known standards, and adjusting parameters accordingly.

Ultrasonic Calibration Steps

Drawing from my calibration experience:

Calibration Steps

-

Preparation Phase

Step Action Purpose Verification System check Diagnostic review Ensure functionality Error check Zero flow Stop flow Set baseline Zero validation Parameter review Configuration check Verify settings Documentation Signal test Strength measurement Quality assurance Signal analysis -

Calibration Process

- Zero point verification

- Span adjustment

- Linearity check

- Repeatability test

Validation Methods

-

Testing Procedures

- Comparison testing

- Volume verification

- Signal analysis

- Performance validation

-

Documentation Requirements

- Calibration records

- Test results

- Parameter settings

- Certification data

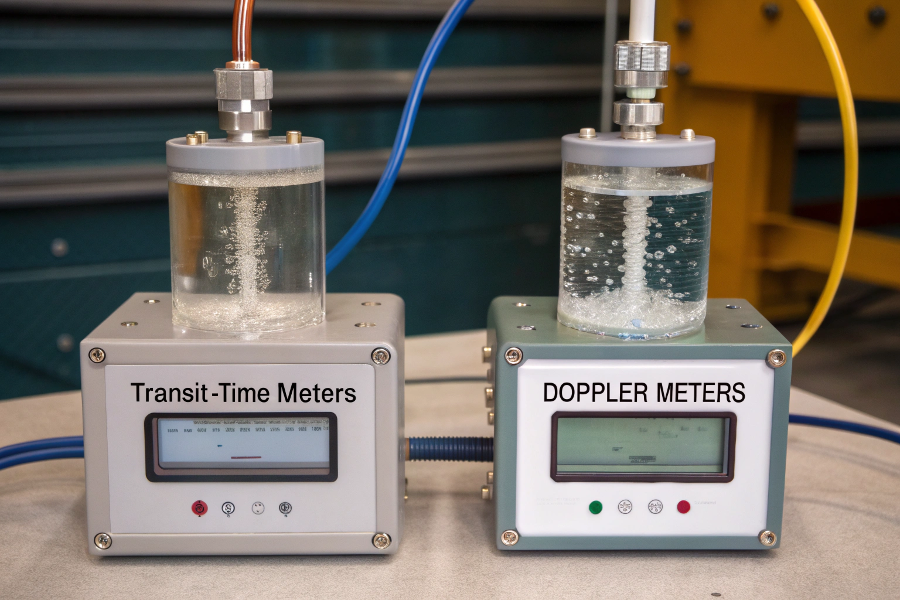

What Are The Two Types Of Ultrasonic Flow Meters?

Selecting the right type of ultrasonic flow meter is crucial for accurate measurement in specific applications.

The two main types are transit-time and Doppler flow meters, each designed for different fluid conditions and measurement requirements.

Ultrasonic Flow Meter Types

From my product expertise:

Type Comparison

-

Transit-Time Meters

Feature Characteristic Application Limitation Principle Time difference Clean liquids Particles affect Accuracy Very high Custody transfer Cost higher Installation Critical Fixed position Space needed Maintenance Minimal Long-term use Regular checks -

Doppler Meters

Feature Characteristic Application Limitation Principle Frequency shift Dirty liquids Particles needed Accuracy Good Process control Less precise Installation Flexible Portable use Signal variation Maintenance Simple Temporary use Regular cleaning

Selection Criteria

-

Application Factors

- Fluid properties

- Accuracy needs

- Installation conditions

- Budget constraints

-

Performance Requirements

- Measurement range

- Response time

- Output options

- Certification needs

Conclusion

Ultrasonic flow meters provide reliable, non-intrusive flow measurement through sound wave technology, with different types suitable for various applications and regular calibration ensuring continued accuracy.