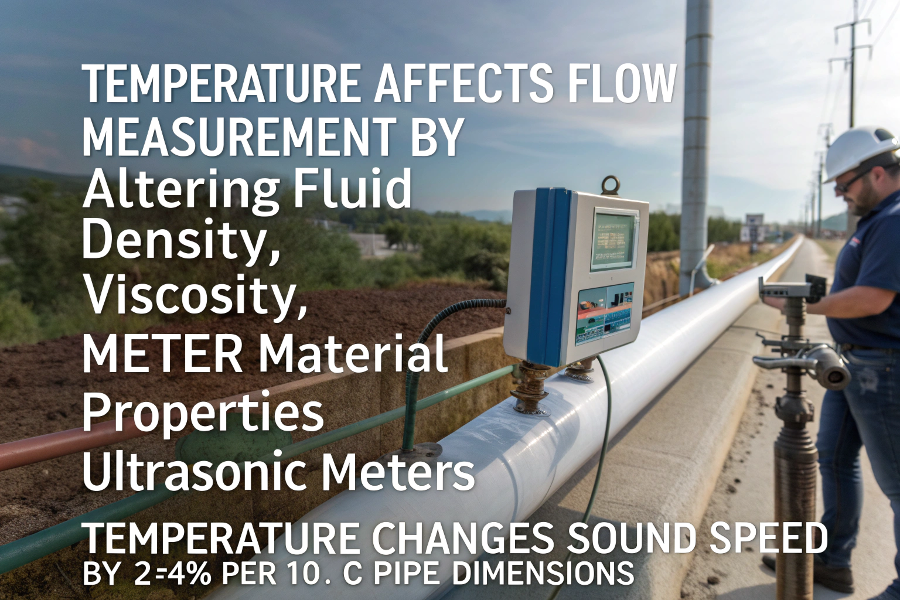

Seeing unexpected flow measurement errors when temperatures change? Temperature impacts every flow meter type differently, often causing significant reading deviations if not properly managed. Even a 10°C variation can create noticeable measurement errors.

Temperature affects flow measurement by changing fluid density, viscosity, and meter material properties. For ultrasonic meters specifically, temperature alters sound speed (2-4% per 10°C) and pipe dimensions (0.02% per °C), requiring compensation algorithms for accurate readings.

Different technologies respond uniquely to thermal effects.

Temperature Impact Factors

The relationship between temperature and flow measurement is complex yet manageable. Let’s analyze how heat and cold influence different measurement principles.

How Does Temperature Affect Ultrasonic Flow Meters?

Three primary thermal effects on ultrasound measurement:

1. Sound Velocity Changes

- Water at 20°C: 1482 m/s

- Water at 80°C: 1555 m/s (+4.9%)

- Compensation requirement: 3 m/s per °C

2. Pipe Dimensional Changes

| Material | Expansion per °C | Effect on 1m path |

|---|---|---|

| Steel | 0.000012 | 12μm change |

| PVC | 0.000080 | 80μm change |

3. Electronic Timing Drift

- Standard oscillators: ±0.5ppm/°C

- High stability: ±0.05ppm/°C

- Path length calculation impact

Ultrasonic Thermal Effects

Compensation Techniques

- Dedicated temp sensors: Measure pipe/fluid temperature

- Multi-path designs: Cancel out some thermal errors

- Reference standards: Known reflectors for calibration

- Advanced algorithms: Dynamic sound speed adjustment

How Does Temperature Affect Flow?

Physical property changes that alter flow:

Fluid Property Changes

| Property | Temperature Effect | Impact on Flow |

|---|---|---|

| Density | Decreases when hot | Mass flow changes |

| Viscosity | Decreases when hot | Turbulence changes |

| Vapor pressure | Increases when hot | Cavitation risk |

Pipe System Effects

- Thermal expansion alters cross-section

- Support stress affects alignment

- Gasket/seal performance changes

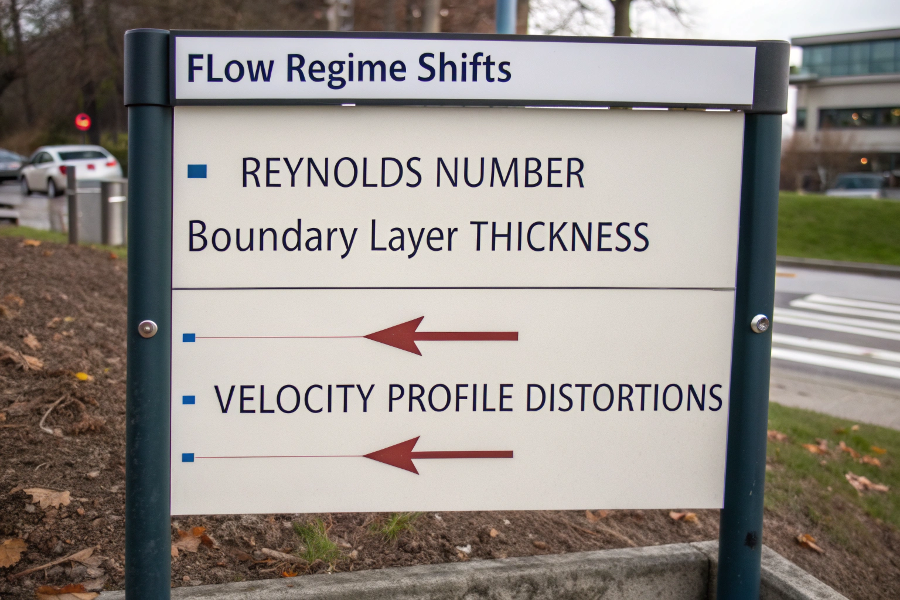

Flow Regime Shifts

- Laminar to turbulent transitions

- Reynolds number changes

- Velocity profile distortions

- Boundary layer thickness variation

Flow Regime Changes

Measurement Technology Differences

- Differential pressure: Affected by density changes

- Coriolis: Minimal temperature sensitivity

- Turbine: Bearing friction changes

- Vortex: Strouhal number shifts

- Positive displacement: Clearance variations

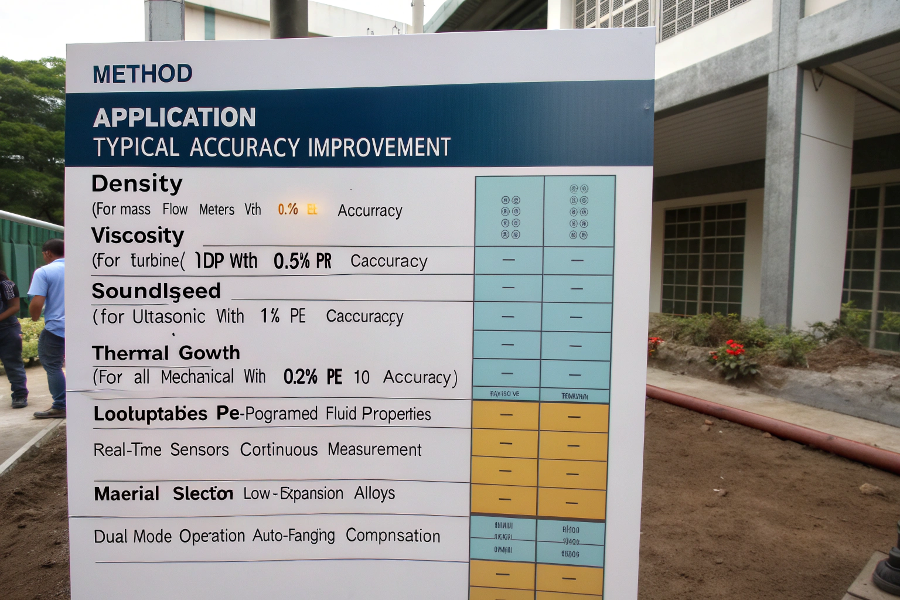

What Is Temperature Compensation for Flow Measurement?

Critical correction methods by technology:

Compensation Types

| Method | Application | Typical Accuracy Improvement |

|---|---|---|

| Density | Mass flow meters | ±0.1% per °C |

| Viscosity | Turbine/PDP | ±0.5% per °C |

| Sound Speed | Ultrasonic | ±1% per °C |

| Thermal Growth | All mechanical | ±0.2% per 10°C |

Implementation Approaches

- Lookup tables: Pre-programmed fluid properties

- Real-time sensors: Continuous measurement

- Material selection: Low-expansion alloys

- Dual-mode operation: Auto-ranging compensation

Compensation Techniques

Industry-Specific Solutions

- Oil & Gas: API-based compensation

- Chemical: Component-specific algorithms

- HVAC: Building automation integration

- Pharma: Validated compensation models

- Food: Sanitary temp sensor designs

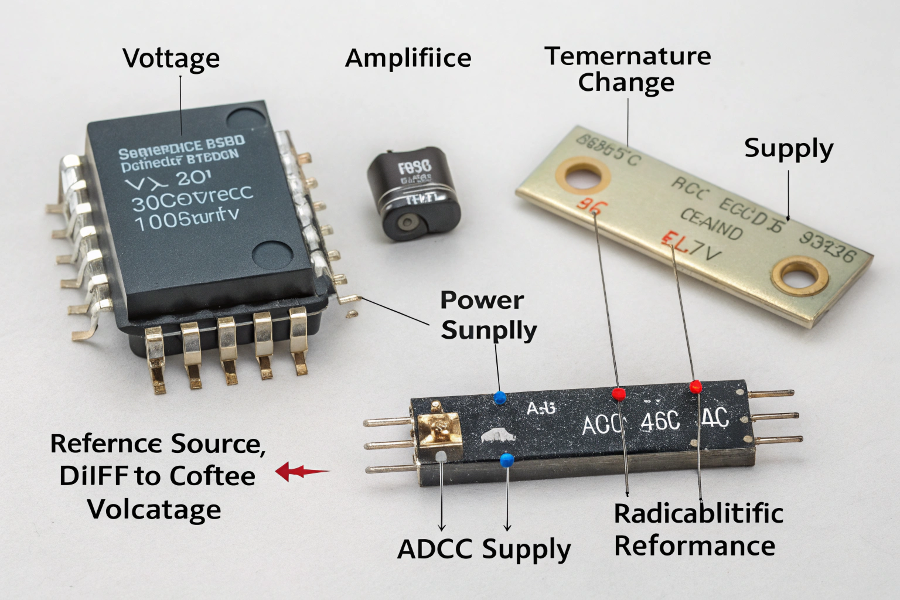

What Is the Effect of Temperature on Current Flow?

Electrical measurement considerations:

Magnetic Flow Meters

| Effect | Low Temp Impact | High Temp Impact |

|---|---|---|

| Electrode potential | Increased noise | Coating risk |

| Lining material | Brittle failure | Softening |

| Fluid conductivity | May decrease | May increase |

Current Signal Transmission

- Copper wire resistance: +0.4%/°C

- Insulation resistance: Halves per 10°C

- Ground potential changes

Electronic Components

- Reference voltage drift

- Amplifier offset changes

- ADC performance variation

- Power supply stability

Electrical Impacts

Mitigation Strategies

- Temperature-stable materials: Constantan electrodes

- Remote electronics: Separate from process

- Digital compensation: Firmware adjustments

- Cooling fins: Heat dissipation

- Thermal barriers: Isolate components

Practical Installation Guidelines

Best Practices

- Sensor placement: Avoid temperature gradients

- Calibration temps: Match operating conditions

- Insulation: Minimize ambient effects

- Verification: Periodic hot/cold checks

Troubleshooting Checklist

| Symptom | Possible Temp Cause | Solution |

|---|---|---|

| Drifting zero | Uncompensated pipe growth | Re-zero at operating temp |

| Spike readings | Localized boiling | Increase backpressure |

| Signal loss | Cable insulation failure | Replace with high-temp wire |

| Accuracy shift | Viscosity change | Recalibrate compensation |

| Intermittent faults | Cyclic thermal stress | Add expansion joints |

Conclusion

Temperature impacts flow measurement through fluid property changes, physical expansions, and electronic drifts, typically introducing 0.1-2% error per 10°C without compensation. Ultrasonic meters are particularly sensitive to sound speed changes (2-4% per 10°C), while all technologies require proper temperature compensation strategies. Modern smart transmitters with integrated temperature compensation can reduce these effects to ±0.1% per 10°C when properly configured. Always verify meter specifications at your operating temperature extremes and consider secondary temperature measurement for critical applications.