Choosing the wrong flow meter can cost thousands in wasted materials or inaccurate billing. The key is knowing which technology fits your specific fluid and conditions.

Magnetic flow meters measure conductive liquids using electromagnetic induction without moving parts, while vortex meters measure any fluid by counting vortices shed from a bluff body. Magnetic meters work only with conductive fluids but offer higher accuracy (0.5%), while vortex meters handle gases/steam with 1% accuracy and don’t require conductivity.

Magnetic Flowmeters

Let me explain these differences in practical detail to help you select the right meter.

What is the Difference Between Vortex and Magnetic Flowmeter?

The working principles create distinct advantages for each technology.

Magnetic flow meters (magmeters) need electrically conductive liquids (water, acids, slurries) and measure the voltage induced by fluid flow through a magnetic field. Vortex meters use a bluff body that creates alternating vortices in all fluid types (steam, gas, liquids) – the vortex frequency corresponds to flow rate.

Here’s how these technologies compare in real installations:

Operating Characteristics Comparison

| Feature | Magnetic Flow Meter | Vortex Flow Meter |

|---|---|---|

| Fluid Type | Only conductive liquids (>5 μS/cm) | All fluids (liquids, gases, steam) |

| Pipe Size | 2mm to 3000mm diameter | 15mm to 300mm diameter |

| Pressure Loss | Minimal (no obstruction) | Moderate (bluff body causes 25-50 kPa drop) |

| Viscosity Limit | No effect | May fail with >30 cP viscosity |

| Installation | Needs 5D upstream pipe | Needs 20D upstream pipe |

Which Type of Flowmeter is Most Accurate?

Accuracy depends on fluid properties and installation conditions.

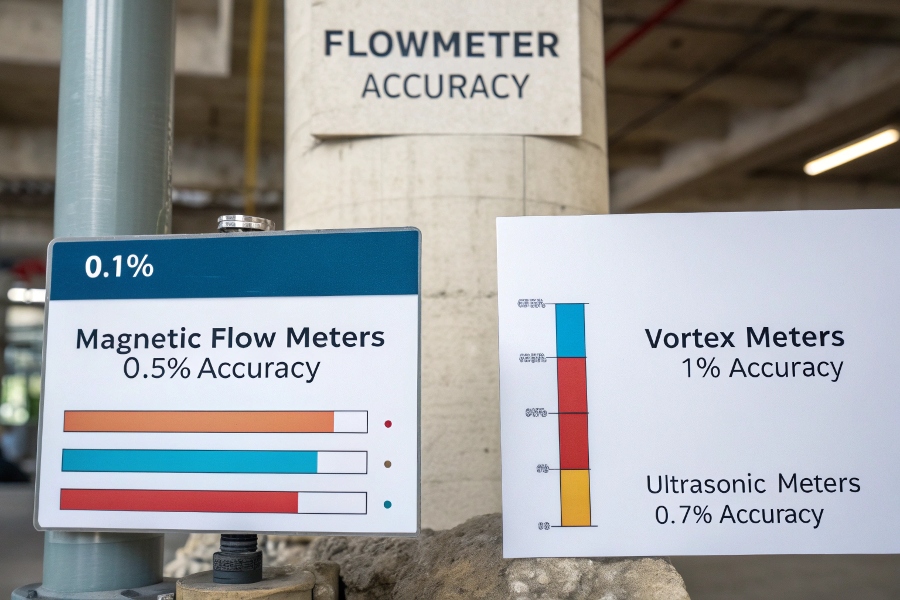

Laboratory-grade Coriolis meters achieve 0.1% accuracy, but for industrial use, magnetic flow meters typically offer 0.5% of rate accuracy with proper calibration. Vortex meters provide 1% accuracy for clean fluids, while ultrasonic meters reach 0.7% with ideal acoustic conditions.

Accuracy Comparison

Several factors actually determine real-world performance:

Accuracy Influencing Factors

Fluid Properties

- Magmeters: Conductivity variations affect readings

- Vortex: Density changes alter vortex street

Flow Profile

- Both types require fully developed flow

- Magmeters tolerate some asymmetry better

Calibration

- Factory calibration vs in-situ calibration

- Temperature compensation necessity

Long-term Stability

- Magmeters: Electrode fouling

- Vortex: Bluff body erosion

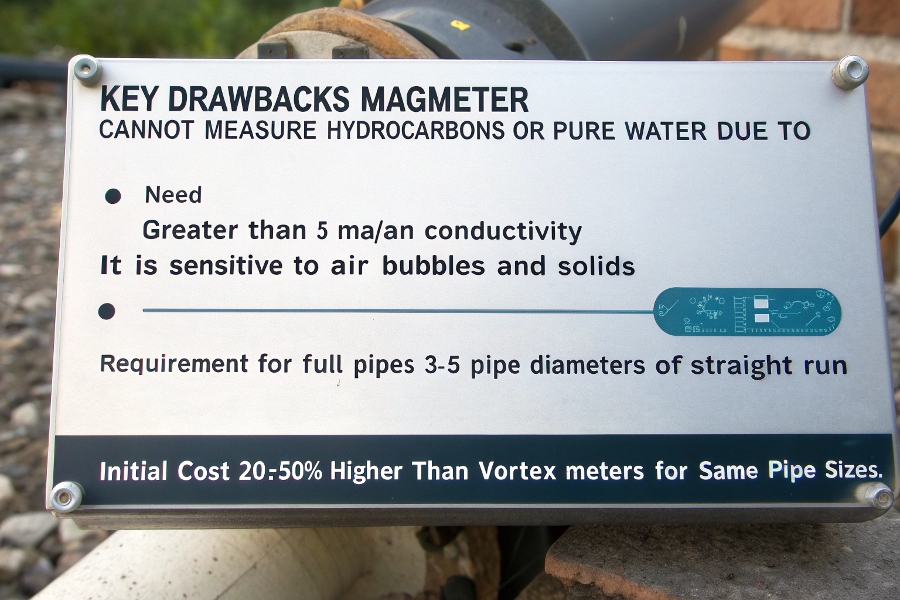

What are the Disadvantages of Magnetic Flow Meter?

Despite their versatility, magmeters have limitations.

Key drawbacks include: can’t measure hydrocarbons or pure water (need >5 μS/cm conductivity), sensitive to air bubbles/solids, require full pipes, and need 3-5 pipe diameters of straight run. Their initial cost is 20-50% higher than vortex meters for same pipe sizes.

Magnetic Meter Constraints

These limitations create specific installation challenges:

Problem Scenarios and Solutions

| Limitation | Problem Example | Mitigation Strategy |

|---|---|---|

| Low Conductivity | Distilled water measurement | Add salts or switch to ultrasonic |

| Partial Pipe Flow | Drain lines with variable levels | Install at downhill section |

| Vibration | Pump discharge piping | Use rigid mounting brackets |

| Coating Buildup | Wastewater with fats | Increase flow velocity >1.5 m/s |

| High Temperature | Steam condensate >150°C | Use PTFE liner instead of rubber |

What are the Three 3 Types of Flow Meters?

The main categories separate by measurement principle.

**1. Velocity Meters (magmeters, vortex, ultrasonic) – measure flow speed × pipe area

- Volumetric Meters (positive displacement, gear) – count fixed fluid volumes

- Mass Flow Meters (Coriolis, thermal) – directly measure mass rather than volume**

Each category serves different industrial needs:

Application-Based Selection Guide

For Custody Transfer (Oil/Gas):

- Coriolis mass flow meters (0.1% accuracy)

- Ultrasonic meters for large pipes

For Water/Wastewater:

- Magnetic flow meters (clamp-on for large pipes)

- Mechanical meters for residential water

For Steam Systems:

- Vortex flow meters (handle saturated/ superheated steam)

- Differential pressure meters

For Chemical Dosing:

- Positive displacement pumps (precise small volumes)

- Micro motion Coriolis meters

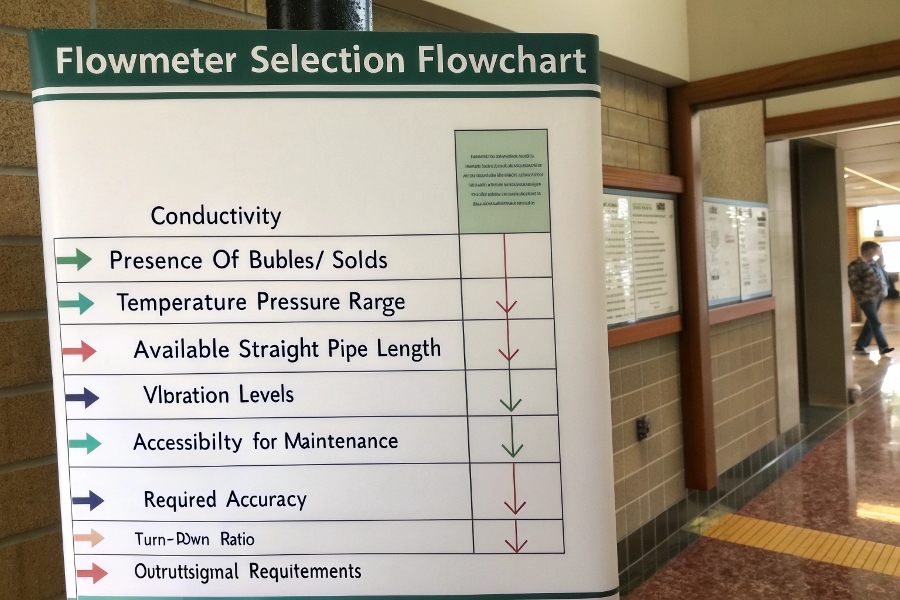

Field Selection Criteria

Practical considerations beyond technical specs.

1. Fluid Characteristics Checklist:

- Conductivity (>5 μS/cm?)

- Presence of bubbles/solids

- Temperature/pressure range

2. Installation Conditions:

- Available straight pipe length

- Vibration levels

- Accessibility for maintenance

3. Performance Needs:

- Required accuracy (billing vs process control)

- Turn-down ratio (max/min flow)

- Output signal requirements

Selection Process

Cost Comparison Over Lifetime

Initial price doesn’t tell the whole story.

| Cost Factor | Magnetic | Vortex |

|---|---|---|

| Purchase Price | $$$ | $$ |

| Installation | $ (flanged/welded) | $$ (needs straighter runs) |

| Maintenance | Electrode cleaning | Bluff body inspection |

| Energy Cost | Low (no pressure drop) | Moderate (permanent loss) |

| Lifetime | 10-15 years | 8-12 years |

Conclusion

Magnetic flow meters excel for conductive liquids needing high accuracy, while vortex meters handle diverse fluids including steam/gas. Consider conductivity, viscosity, and installation space – where magmeters need conductivity but tolerate poor flow profiles, vortex meters work universally but demand clean, steady flows. For water/wastewater, magmeters usually win; for steam or compressed air, vortex meters dominate. Always match the technology to your specific fluid properties and accuracy requirements.