Choosing between electromagnetic (mag) and ultrasonic flow meters can make or break your measurement system. Getting this wrong leads to inaccurate readings, maintenance nightmares, and costly downtime.

The core difference is measurement principle: mag meters (EMF) require conductive fluids and measure voltage changes from magnetic fields (accuracy ±0.5%), while ultrasonic meters use sound wave transit times that work on most liquids/gases (accuracy ±1-2%). EMFs need full pipes with conductivity >5μS/cm, while ultrasonics work on non-conductive fluids like oil but suffer with aerated liquids.

Measurement Principle Comparison

Let’s break down how these differences impact real-world performance.

What Is the Difference Between Ultrasonic and Electromagnetic Waves?

The underlying physics dictate their application limits.

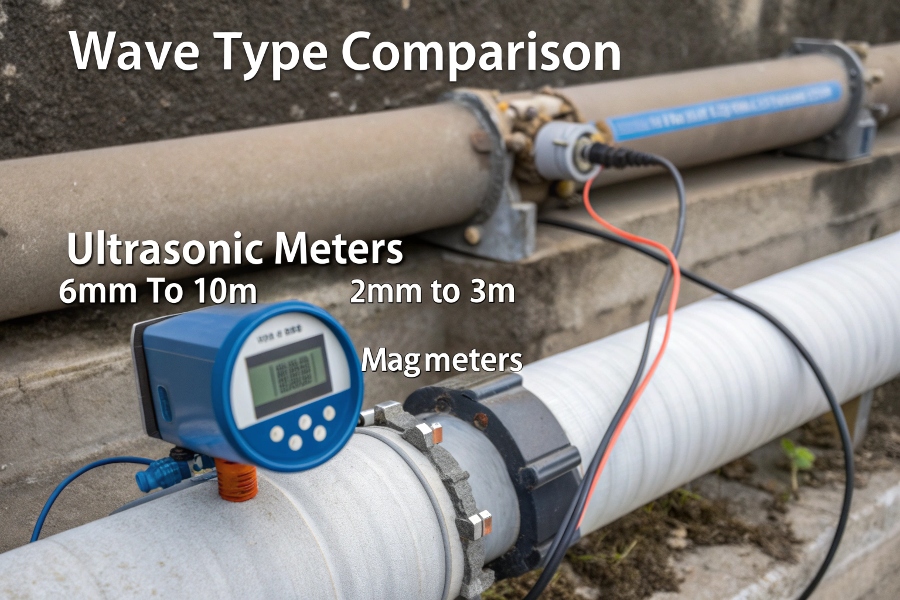

Ultrasonic meters use 0.5-2MHz sound waves (travel time difference), suitable for pipes 6mm-10m diameter. Mag meters generate 50-200Hz electromagnetic fields (Faraday’s Law), limited to pipes 2mm-3m diameter. Ultrasound works through pipe walls (clamp-on possible), while EMF requires direct fluid contact with electrodes.

Wave Type Comparison

Technical specifications reveal critical constraints:

Wave-Based Flow Meter Constraints

| Parameter | Electromagnetic | Ultrasonic |

|---|---|---|

| Fluid Conductivity | >5μS/cm required | No requirement |

| Minimum Pipe Size | 2mm | 6mm (clamp-on: 15mm) |

| Maximum Pipe Size | 3m | 10m |

| Wave Frequency | 50-200Hz | 0.5-2MHz |

| Penetration Depth | Surface only | Through pipe wall |

Which Type of Flowmeter Is Most Accurate?

Accuracy claims require context – lab specs ≠ field performance.

Under ideal conditions: Mag meters achieve ±0.5% rate, ±0.2% with calibration. Ultrasonic meters reach ±1% (transit-time), ±2-5% (Doppler). However, mag meter accuracy plummets to ±5% if conductivity varies, while ultrasonic suffers ±10% errors with bubbles/solids.

Accuracy Under Various Conditions

Real-world accuracy factors:

Accuracy Degradation Causes

| Flow Meter Type | Primary Accuracy Killers | Error Increase |

|---|---|---|

| Electromagnetic | Low conductivity, electrode coating | ±0.5% → ±5% |

| Ultrasonic (Transit-time) | Air bubbles, pipe scaling | ±1% → ±10% |

| Ultrasonic (Doppler) | Particle concentration changes | ±2% → ±15% |

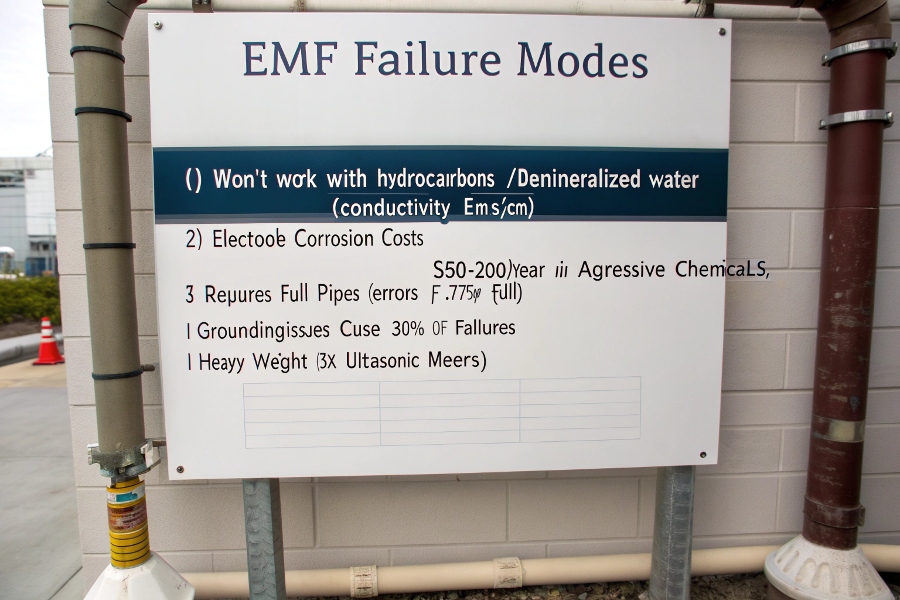

What Are the Disadvantages of Electromagnetic Flow Meter?

Understanding EMF limitations prevents costly misapplications.

Key drawbacks: 1) Won’t work with hydrocarbons/demineralized water (conductivity<5μS/cm), 2) Electrode corrosion costs $500-2000/year in aggressive chemicals, 3) Requires full pipes (errors if <75% full), 4) Grounding issues cause 30% of failures, 5) Heavy weight (3x ultrasonic meters).

EMF Failure Modes

Failure cost analysis shows hidden expenses:

EMF Operational Issues & Costs

| Problem | Frequency | Repair Cost | Downtime Impact |

|---|---|---|---|

| Electrode coating | 25% annual | $500 | 4-8 hours |

| Liner damage | 10% in 5 years | $1500+ | 1-3 days |

| Grounding faults | 30% of failures | $700 | 8-24 hours |

| Zero drift | 15% annual | $300 | 2-4 hours |

What Are the Disadvantages of an Ultrasonic Flowmeter?

Ultrasonic technology has surprising limitations users often discover too late.

Top issues: 1) Bubbles/solids cause 50% accuracy loss, 2) Installation errors create 30% variance (couplant decay, misalignment), 3) Pipe material matters (fails on lined/coated pipes), 4) High power needs (3-5W vs mag’s 0.5W), 5) Clamp-on types fail below 0.3m/s flow velocity.

Ultrasonic Challenges

Installation requirements often surprise users:

Ultrasonic Performance Requirements

| Condition | Effect on Performance | Mitigation Cost |

|---|---|---|

| Pipe scaling >1mm | ±5% error increase | $2000 cleaning |

| Flow <0.3m/s | No measurement | $4000 booster pump |

| 2% air bubbles | ±10% error | $1500 degasser |

| Pipe vibration | Signal loss | $800 dampeners |

| Temperature swings | ±3% drift | $600 insulation |

Selection Guide: When to Choose Which

Matching technology to application prevents 80% of flow measurement failures.

Choose electromagnetic when: conductive fluids (acids, water), slurry applications, 0.5% accuracy needs. Select ultrasonic when: non-conductive fluids (oils), large pipe diameters (>300mm), chemical-free installation needed.

Technology Selection

Decision matrix for common scenarios:

Flow Meter Selection Guide

| Application | EMF Suitability | Ultrasonic Suitability |

|---|---|---|

| Wastewater | Excellent | Poor (solids/bubbles) |

| Diesel fuel | Impossible | Good |

| Sulfuric Acid | Excellent | Dangerous |

| Demineralized water | No | Partial (air risks) |

| High-purity chemicals | Risky (contamination) | Best option |

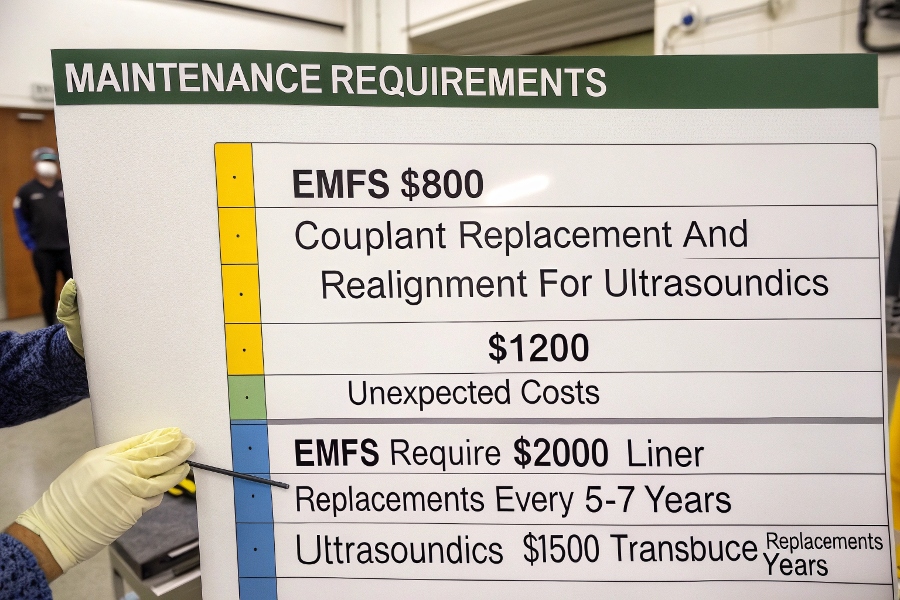

Maintenance Comparison

Long-term costs differ dramatically between technologies.

Annual EMF costs: $800 (electrode cleaning/calibration). Ultrasonic: $1200 (couplant replacement/realignment). Unexpected costs: EMFs suffer $2000 liner replacements every 5-7 years; ultrasonics need $1500 transducers after 8-10 years.

Maintenance Requirements

Detailed maintenance schedules:

Recommended Maintenance Actions

| Task | EMF Frequency | Ultrasonic Frequency | Cost |

|---|---|---|---|

| Calibration | Annual | Biannual | $400 |

| Electrode Check | Quarterly | N/A | $150 |

| Couplant Refresh | N/A | 6 months | $200 |

| Signal Check | Monthly | Weekly | $50 |

| Full Inspection | 3 years | 2 years | $800 |

Conclusion

Electromagnetic flow meters excel with conductive fluids needing high accuracy, despite maintenance demands. Ultrasonic meters offer versatile non-invasive measurement but struggle with variable flows. Smart selection requires evaluating conductivity, accuracy needs, and willingness to perform maintenance – getting this right ensures years of reliable service.