Measuring sludge flow accurately can be challenging due to its varying consistency and high solid content.

For sludge applications, electromagnetic flow meters are typically the best choice due to their ability to handle high solid content, no moving parts, and maintenance-friendly design.

%(percentage)sludge-flowmeter

Sludge Flow Meter Application

Let me share insights from my experience in implementing flow measurement solutions for various sludge applications.

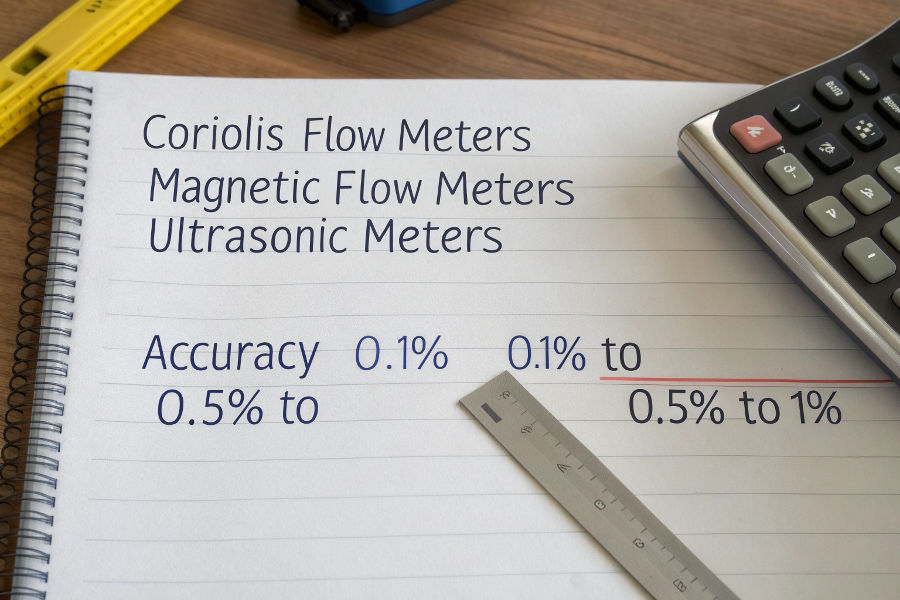

Which Type Of Flowmeter Is Most Accurate?

Accuracy requirements often drive the selection of flow measurement technology.

Coriolis flow meters generally provide the highest accuracy (±0.1%), followed by magnetic flow meters (±0.2-0.5%) and ultrasonic meters (±0.5-1%).

Flow Meter Accuracy Comparison

Based on my technical expertise:

Accuracy Comparison

-

Technology Overview

Flow Meter Type Typical Accuracy Best Applications Limitations Coriolis ±0.1% Clean liquids High cost Magnetic ±0.2-0.5% Conductive fluids Requires conductivity Ultrasonic ±0.5-1% Clean liquids Affected by bubbles Vortex ±1% Steam, gas Min flow requirement -

Selection Factors

- Process fluid properties

- Operating conditions

- Installation requirements

- Budget constraints

Performance Optimization

-

Installation Considerations

- Proper straight runs

- Grounding requirements

- Vibration isolation

- Temperature effects

-

Maintenance Requirements

- Regular calibration

- Cleaning procedures

- Electrode inspection

- Signal verification

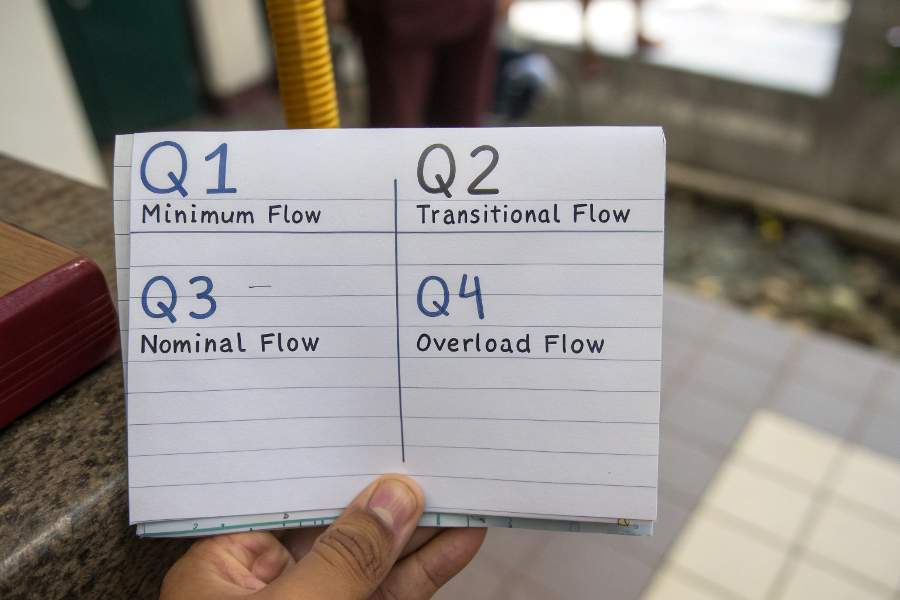

What Is Q1 Q2 Q3 Q4 Flow Meter?

Flow meter accuracy classes can be confusing for many users.

Q ratings (Q1, Q2, Q3, Q4) represent the flow range characteristics of a meter, where Q1 is minimum flow, Q2 is transitional flow, Q3 is nominal flow, and Q4 is overload flow.

Flow Meter Q Ratings Explained

From my measurement experience:

Q Rating System

-

Flow Range Definitions

Rating Description Typical Range Application Q1 Minimum Flow 1-2% of Q3 Low flow accuracy Q2 Transition Flow 1.6 x Q1 Accuracy change point Q3 Nominal Flow Design flow Normal operation Q4 Maximum Flow 1.25 x Q3 Peak conditions -

Performance Implications

- Measurement accuracy

- Operating range

- Pressure loss

- Energy consumption

Application Guidelines

-

Selection Criteria

- Flow profile analysis

- System requirements

- Operating conditions

- Accuracy needs

-

Installation Requirements

- Proper sizing

- Flow conditioning

- Pressure considerations

- Maintenance access

What Is The Flowmeter For Effluent?

Effluent flow measurement requires special consideration due to varying fluid properties.

For effluent applications, magnetic flow meters and ultrasonic flow meters are most commonly used due to their non-intrusive nature and ability to handle varying fluid compositions.

%(percentage)effluent-meter

Drawing from my installation experience:

Effluent Meter Selection

-

Technology Comparison Meter Type Advantages Challenges Best For Magnetic No moving parts Requires conductivity Mixed effluent Ultrasonic Non-contact Affected by bubbles Clean effluent Area-Velocity Works in partial pipes Regular maintenance Variable flows Open Channel Simple operation Requires free discharge Treatment plants -

Application Factors

- Flow characteristics

- Solid content

- Chemical composition

- Installation location

Implementation Strategy

-

System Design

- Flow range analysis

- Material compatibility

- Power requirements

- Data collection needs

-

Operational Considerations

- Maintenance schedule

- Cleaning requirements

- Calibration intervals

- Performance monitoring

How Do You Measure Wastewater Flow?

Wastewater flow measurement presents unique challenges requiring specialized solutions.

Wastewater flow is typically measured using a combination of level and velocity measurements, with magnetic flow meters for full pipes and area-velocity meters for partially filled pipes.

Wastewater Flow Measurement Methods

Based on my field experience:

Measurement Techniques

-

Method Selection

Method Application Benefits Limitations Area-Velocity Partial pipes No restrictions Regular cleaning Magnetic Full pipes High accuracy Installation cost Open Channel Treatment plants Simple operation Space requirements Doppler High solids Non-invasive Limited accuracy -

Installation Requirements

- Access points

- Straight runs

- Power supply

- Signal transmission

System Integration

-

Data Management

- Recording methods

- Analysis tools

- Reporting systems

- Alarm protocols

-

Maintenance Program

- Inspection schedules

- Cleaning procedures

- Calibration plans

- Troubleshooting guides

Conclusion

The best flow meter for sludge applications depends on specific requirements, but electromagnetic flow meters generally offer the optimal combination of accuracy, reliability, and maintenance efficiency for most sludge applications.