Many engineers struggle with flow measurement accuracy, often wondering if their vortex meters deliver the precision they need.

Vortex flow meters typically achieve accuracy rates of ±0.5% to ±1.0% of reading for liquids and ±1.0% to ±2.0% for gases and steam, with excellent repeatability.

Flow Meter Accuracy Comparison

Let me share insights from my experience with various flow measurement technologies.

Which Flow Meter Is Most Accurate?

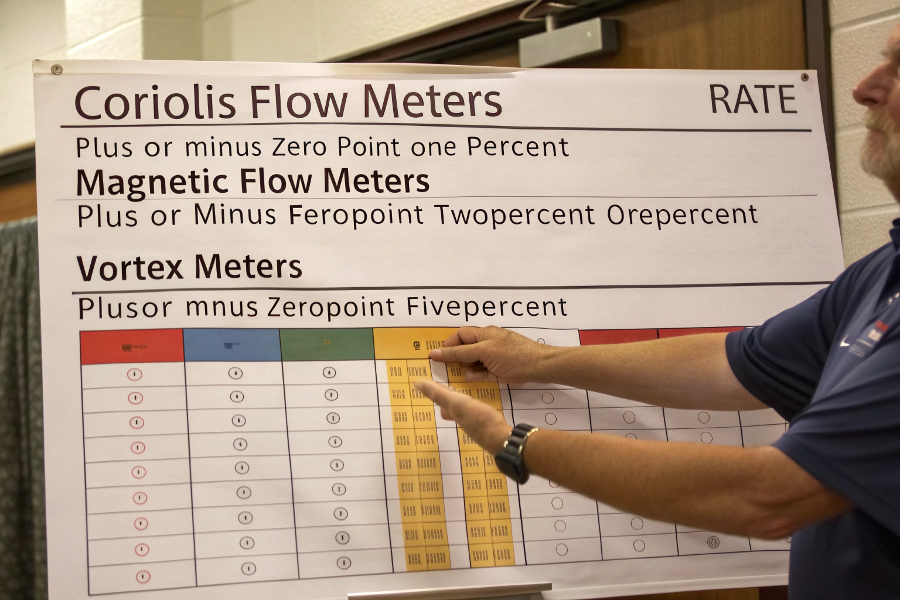

Choosing between flow meter technologies often comes down to accuracy requirements.

Coriolis flow meters provide the highest accuracy at ±0.1% of rate, followed by magnetic flow meters at ±0.2%, while vortex meters typically achieve ±0.5% to ±1.0%.

Flow Meter Accuracy Chart

Here’s my detailed analysis:

Accuracy Comparison

Flow Meter Technologies

Type Typical Accuracy Best Application Coriolis ±0.1% High-precision custody transfer Magnetic ±0.2% Conductive liquids Vortex ±0.5-1.0% Steam and gases Turbine ±0.5-1.0% Clean liquids Influencing Factors

- Fluid properties

- Installation conditions

- Flow profile

- Environmental conditions

Selection Criteria

Application Requirements

- Process conditions

- Required accuracy

- Cost considerations

- Maintenance needs

Performance Factors

- Turndown ratio

- Repeatability

- Long-term stability

- Response time

What Are The Limitations Of Vortex Flow Meter?

Understanding limitations helps prevent application mistakes and measurement errors.

Key limitations include minimum flow requirements, sensitivity to vibration, straight pipe run requirements, and unsuitable for low-velocity or highly viscous fluids.

Vortex Flow Meter

From my field experience:

Technical Limitations

Operating Constraints

Limitation Impact Solution Minimum flow No measurement Proper sizing Vibration Signal interference Isolation mounting Reynolds number Accuracy affected Application review Straight run Installation space Flow conditioners Application Restrictions

- Viscous fluids

- Two-phase flow

- Pulsating flow

- Low pressure

Installation Requirements

Physical Considerations

- Pipe orientation

- Support structure

- Access requirements

- Environmental protection

Process Requirements

- Flow stability

- Fluid composition

- Operating conditions

- Maintenance access

How Do I Know If My Vortex Flow Meter Is Accurate?

Verification of flow meter accuracy is crucial for process control and billing applications.

Regular calibration, comparison with reference meters, monitoring of diagnostic parameters, and analysis of historical data help verify flow meter accuracy.

Based on my experience:

Verification Methods

Testing Procedures

Method Frequency Benefits Calibration Annually Traceable results Comparison Monthly Quick verification Diagnostics Continuous Real-time monitoring Data analysis Quarterly Trend identification Performance Indicators

- Zero stability

- Repeatability

- Signal strength

- Error messages

Maintenance Program

Regular Checks

- Visual inspection

- Signal validation

- Zero verification

- Span check

Documentation Requirements

- Calibration records

- Maintenance history

- Performance trends

- Incident reports

What Are The Disadvantages Of Vortex?

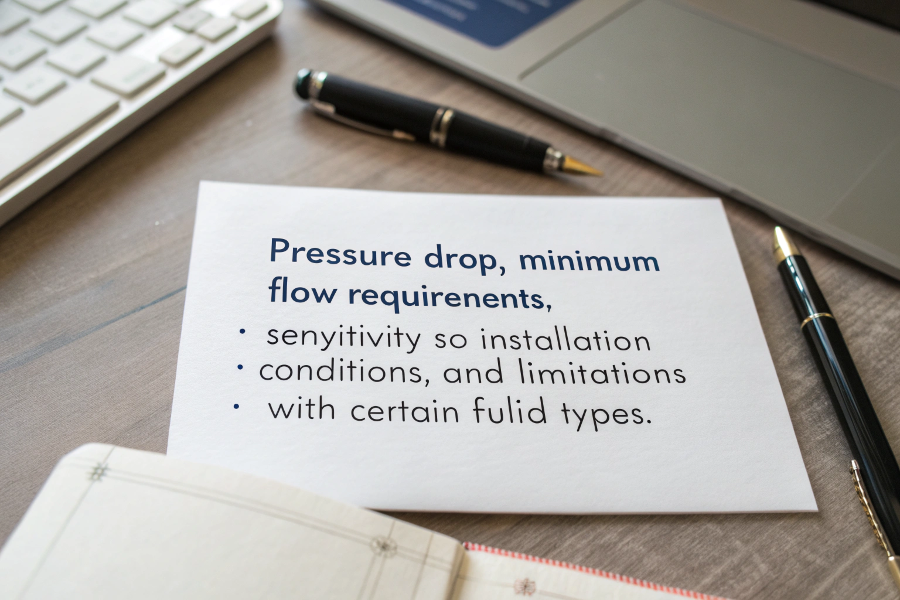

Understanding drawbacks helps make informed decisions about meter selection.

Major disadvantages include pressure drop, minimum flow requirements, sensitivity to installation conditions, and limitations with certain fluid types.

Vortex Flow Meter Disadvantages

Vortex Flow Meter Disadvantages

Let me explain the key issues:

Primary Disadvantages

Operational Issues

Disadvantage Impact Mitigation Pressure drop Energy cost Proper sizing Flow range Limited turndown Multiple meters Installation Space requirements Good planning Maintenance Regular cleaning Easy access Application Limitations

- Low flow rates

- High viscosity

- Dirty fluids

- Variable processes

Cost Considerations

Initial Investment

- Purchase price

- Installation costs

- Training requirements

- Spare parts

Operating Expenses

- Energy consumption

- Maintenance costs

- Calibration expenses

- Replacement parts

Conclusion

While vortex flow meters offer good accuracy and reliability, success depends on proper application understanding, correct installation, and regular maintenance to maintain measurement accuracy.