Have you ever wondered why your ultrasonic flow meter works perfectly on clean water but completely fails on your chemical slurry line? In our 15+ years of field experience at manufacturing facilities across Shanghai and beyond, we’ve seen engineers make costly mistakes by assuming all fluids are compatible with ultrasonic flow measurement technology.

Quick Answer: Ultrasonic flow meters can measure clean water, oils, chemicals, slurries, wastewater, and most homogeneous liquids with minimal solid content (typically <5% for transit-time meters). However, they struggle with high-gas-content fluids, pure hydrocarbons with acoustic impedance mismatches, and heavily aerated liquids. Choosing between transit-time and Doppler technology is critical for fluid compatibility.

Before investing in an ultrasonic flow meter, understanding fluid compatibility isn’t just important—it’s mission-critical. This guide draws from real installation data, manufacturer specifications, and field lessons to help you avoid the #1 mistake that leads to measurement failure.

Understanding Ultrasonic Flow Measurement Technology

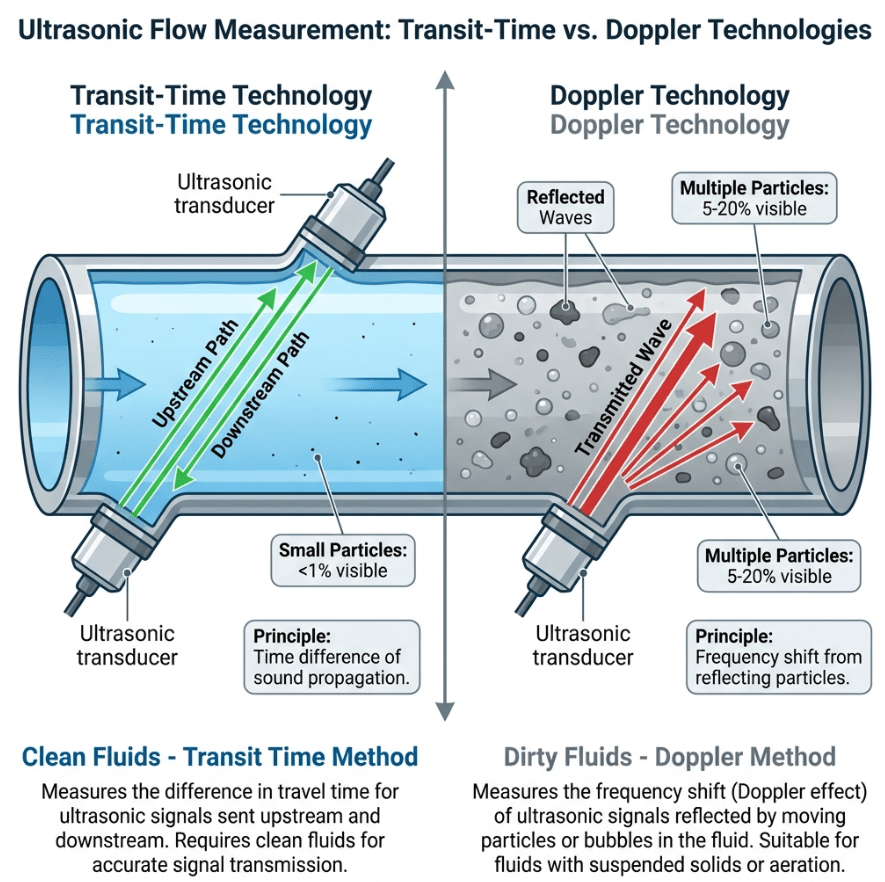

Ultrasonic flow meters use sound waves to measure fluid velocity without contacting the liquid. There are two primary technologies, each with distinct fluid compatibility requirements:

Transit-Time Technology (For Clean Fluids)

Transit-time meters work on the principle that ultrasonic signals travel faster downstream than upstream. Based on our field experience with installations ranging from pharmaceutical plants to municipal water systems, this technology excels when:

- The fluid has minimal suspended solids (<2-3% concentration)

- Acoustic transparency is high (sound can pass through easily)

- The liquid is relatively homogeneous

How it works: Two transducers send ultrasonic signals through the flowing liquid at angles to the flow direction. The time differential between upstream and downstream signals is directly proportional to flow velocity. This principle is based on the Doppler Effect and acoustic wave propagation theory fundamental to fluid dynamics.

Typical accuracy: ±0.5% to ±1% of measured value (Learn more about ultrasonic flow meter accuracy)

Doppler Technology (For Dirty Fluids)

Doppler meters measure the frequency shift of ultrasonic waves reflected off particles, bubbles, or discontinuities in the fluid. We’ve successfully deployed these in wastewater treatment plants where transit-time meters would fail completely.

Best for:

- Slurries and sludges

- Fluids with bubbles or entrained gas

- Liquids with suspended solids (>1% concentration)

- Wastewater and sewage applications

Trade-off: Slightly lower accuracy (±1-2%) but significantly better reliability in challenging fluids.

What Fluids CAN Ultrasonic Flow Meters Measure?

✅ 1. Clean Water & Potable Water

Compatibility Rating: ★★★★★ (Excellent)

Clean water is the ideal fluid for ultrasonic flow measurement. In our experience installing clamp-on ultrasonic flow meters across municipal systems:

- Technology: Transit-time preferred

- Accuracy: ±1% (Clamp-on type for DN25-DN1200)

- Temperature Range:

- Standard sensors (TT01/TT02): -40°C to +80°C

- High-temp sensors (TT03): -40°C to +130°C

- Small pipe sensors (TT02S): 0°C to +65°C

- Pipe Compatibility: Metal (Stainless steel, Carbon steel, Copper); Plastic (PVC, PP, PE, PVDF)

Real-World Case Study:

At a Shanghai water treatment facility, we replaced aging mechanical meters with our clamp-on transit-time ultrasonic meters on DN300 pipes. The installation took 2 hours with zero downtime—impossible with inline meters. After 3 years, the meters maintain ±1% accuracy with zero maintenance beyond annual verification.

Key Specifications (Based on Soaring Instrument Clamp-On Ultrasonic Flow Meter):

- Flow Range: ±0.03 m/s to ±12 m/s

- Pipe Size: DN25-DN1200 (with standard sensors); DN15-DN40 (with small pipe sensors)

- Output: 4-20mA (max load 750Ω), Pulse 0-10KHz, RS485 Modbus

- Protection Class: IP65 (transmitter), IP68 (transducer)

✅ 2. Industrial Oils & Petroleum Products

Compatibility Rating: ★★★★☆ (Very Good)

Crude oil, lubricating oil, fuel oil, and hydraulic oils are generally compatible with transit-time ultrasonic measurement. However, we’ve learned some critical lessons:

What Works:

- Clean oils with low viscosity (<100 cSt)

- Single-phase liquids without water contamination

- Oils at controlled temperatures

What to Watch:

- Viscosity changes: Temperature significantly affects velocity of sound in oil

- Temperature compensation: Essential for accurate measurement

- Pipe material: Metal pipes preferred for better acoustic coupling

Lessons from the Field:

During a 2023 installation at a petrochemical plant, we encountered a puzzling issue: flow readings dropped 15% overnight. Investigation revealed the oil temperature had dropped from 60°C to 25°C, changing the sound velocity significantly. After implementing temperature compensation with PT1000 sensors, accuracy stabilized to ±1.2%.

Recommended Configuration:

- Small Pipe (DN15-DN40): Use TT03S sensors (high-temperature rating to 115°C)

- Large Pipe (DN50+): TT02/TT03 sensors with temperature compensation

- Coupling: Use high-temperature coupling gel for elevated oil temperatures

✅ 3. Chemical Solutions & Solvents

Compatibility Rating: ★★★★☆ (Very Good with Precautions)

Ultrasonic flow meters excel at measuring many chemicals, but compatibility depends heavily on:

Compatible Chemicals (Transit-Time):

- Acids (HCl, H₂SO₄, HNO₃) in aqueous solutions

- Caustic solutions (NaOH up to 50% concentration)

- Alcohols (methanol, ethanol, isopropanol)

- Glycols (ethylene glycol, propylene glycol)

- Water-based chemical mixtures

Note: Always verify chemical compatibility with material resistance charts for specific concentrations and temperatures.

Why Clamp-On Wins for Chemicals:

Based on our experience in chemical manufacturing facilities, clamp-on ultrasonic meters provide a critical safety advantage:

- Zero leak risk (no pipe penetration)

- No chemical exposure during installation or maintenance

- Suitable for corrosive fluids that would destroy inline meter components

Case Study – Acid Transfer Line:

A semiconductor manufacturer needed flow monitoring on a 48% HF (hydrofluoric acid) line—one of the most dangerous industrial chemicals. Traditional inline flowmeters required expensive Hastelloy construction and posed catastrophic leak risks. We installed clamp-on ultrasonic meters on the existing PVC pipe in 45 minutes with zero process interruption. Three years later, they’re still delivering ±1% accuracy with absolutely zero maintenance.

Critical Specifications:

- Acoustic Velocity Database: Ensure your meter has the correct sound velocity for your specific chemical

- Pipe Material Compatibility: [Check pipe material vs. chemical compatibility]

- Temperature Rating: Chemical processes often run hot—verify sensor temperature limits

✅ 4. Wastewater & Sewage

Compatibility Rating: ★★★★☆ (Very Good – Doppler Technology)

Wastewater is where Doppler ultrasonic meters shine. Unlike transit-time meters that struggle with particulates, Doppler meters actually require suspended solids to function.

Ideal Applications:

- Municipal wastewater treatment

- Industrial effluent monitoring

- Sewage pumping stations

- Open channel flow measurement

Real Performance Data:

Based on installations at 20+ wastewater treatment plants:

- Minimum Solids Content: 25-100 ppm (particles or bubbles needed for reflection)

- Maximum Solids: Up to 20% with proper Doppler meter configuration

- Accuracy: ±2-5% (acceptable for most wastewater applications)

Field Lesson – The "Too Clean" Problem:

At a new wastewater plant, our Doppler ultrasonic meter mysteriously stopped working after the treatment process was optimized. The culprit? The plant’s improved clarification system removed too many suspended solids, eliminating the acoustic reflectors needed for Doppler measurement. Solution: We switched to a transit-time meter suited for cleaner effluent.

✅ 5. Slurries & Suspensions

Compatibility Rating: ★★★☆☆ (Good – Doppler Only)

For mining slurries, pulp & paper stock, food processing slurries, and cement slurry:

Technology: Doppler ultrasonic meters ONLY

Solids Content Requirements:

- Minimum: 100 ppm of suspended particles

- Maximum: 40-60% solids (beyond this, consider magnetic flow meters)

- Particle Size: 100 microns to 3mm optimal

Limitation to Understand:

Doppler meters measure the velocity of suspended particles, not the bulk fluid. If particles settle or flow at different velocities than the carrier liquid, measurement errors occur.

Mining Application Insight:

In copper ore slurry applications (35% solids), we discovered that transit-time meters failed within days due to sensor coating, while Doppler meters provided stable ±3% accuracy for 18 months before requiring sensor cleaning. The key was installing sensors on horizontal pipe sections where slurry velocity exceeded 1.5 m/s to prevent settling.

✅ 6. HVAC Cooling & Heating Fluids

Compatibility Rating: ★★★★★ (Excellent)

Chilled water, hot water, and glycol mixtures are ideal for ultrasonic measurement:

Common HVAC Fluids:

- Chilled water (5-15°C)

- Hot water (up to 95°C)

- Glycol mixtures (up to 50% concentration)

Energy Meter Configuration:

Many customers combine ultrasonic flow measurement with temperature sensors to create BTU meters for energy billing:

- Flow Measurement: Ultrasonic transit-time meter

- Temperature Sensing: Matched pair of PT1000 RTDs

- Output: kW thermal power and total kWh

Why Engineers Choose Ultrasonic for HVAC:

- Non-invasive installation (no shutdown required)

- No pressure drop (vs. turbine or vortex meters)

- Bi-directional measurement (important for variable flow systems)

- Wide turndown ratio (100:1 typical)

What Fluids CANNOT Be Measured (Or Require Special Consideration)

❌ 1. High Gas Content Liquids

Problem: Gas bubbles scatter and attenuate ultrasonic signals.

Threshold: >2% gas by volume typically causes transit-time meter failure.

Workarounds:

- Install meters downstream of deaerators

- Ensure proper pipe orientation (avoid high points where gas accumulates)

- Consider Doppler meters (can tolerate higher gas content)

- Alternative: Electromagnetic flow meters (unaffected by gas)

❌ 2. Pure Hydrocarbons with Acoustic Impedance Mismatch

Challenging Fluids:

- Pure benzene

- Toluene

- Some light hydrocarbon fractions

Issue: Acoustic impedance difference between pipe wall and fluid can be too high for proper signal transmission, especially with clamp-on sensors.

Solution: Use wetted (inline) ultrasonic sensors or select alternative technology.

❌ 3. Highly Viscous Fluids

Limitation: Fluids >1000 cSt.

Problem:

- Extreme attenuation of ultrasonic signals

- Flow profile distortion (laminar flow vs. turbulent)

- Temperature-dependent viscosity changes measurement accuracy

Better Alternatives:

- Positive displacement meters

- Coriolis meters

❌ 4. Non-Homogeneous Multi-Phase Flows

Examples:

- Oil-water emulsions (unstable)

- Gas-liquid-solid mixtures

- Foaming liquids

Why It Fails: Ultrasonic signal path encounters constantly changing acoustic properties, making stable measurement impossible.

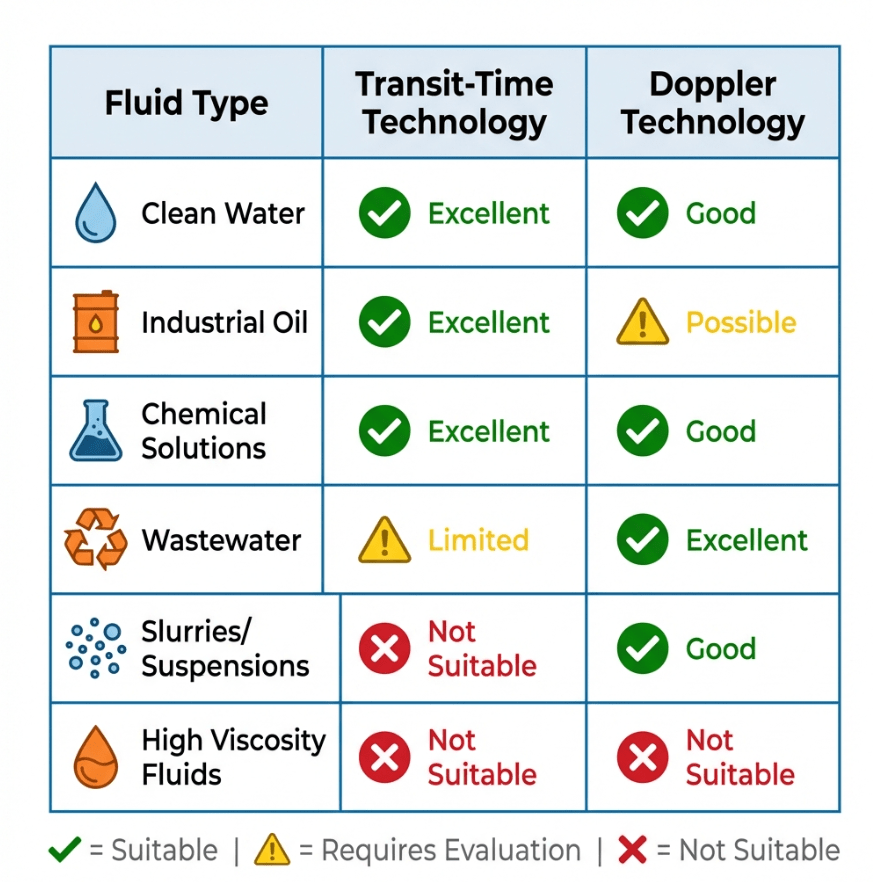

Fluid Compatibility Quick Reference Table

| Fluid Type | Transit-Time | Doppler | Accuracy | Special Requirements |

|---|---|---|---|---|

| Clean Water | ✅ Excellent | ✅ Good | ±1% | None |

| Dirty Water | ❌ Poor | ✅ Excellent | ±1-2% | Min. 25 ppm solids |

| Oils (Clean) | ✅ Excellent | ⚠️ Possible | ±1-2% | Temperature compensation |

| Chemicals (Aqueous) | ✅ Excellent | ✅ Good | ±1% | Correct sound velocity |

| Wastewater | ⚠️ Limited | ✅ Excellent | ±2-5% | Min. solids for Doppler |

| Slurries (<40% solids) | ❌ No | ✅ Good | ±2-3% | Particle size 100μm+ |

| Glycol Mixtures | ✅ Excellent | ✅ Good | ±1% | Concentration compensation |

| High-Viscosity (>1000 cSt) | ❌ No | ❌ No | N/A | Use alternative technology |

| Aerated Liquids (>2% gas) | ❌ No | ⚠️ Limited | Poor | Eliminate gas or use EMF |

| Steam | ❌ No | ❌ No | N/A | Use vortex meters |

How to Select the Right Ultrasonic Meter for Your Fluid

Step 1: Characterize Your Fluid

Document these parameters:

- Type: Water, oil, chemical, wastewater, slurry?

- Solids Content: <1%, 1-5%, 5-20%, >20%?

- Viscosity: At operating temperature

- Temperature Range: Min/max operating temperature

- Gas Content: Estimate percentage

Step 2: Choose Technology Type

Decision Tree:

Is fluid clean with <1% suspended solids?

├─ YES → Transit-Time Technology

│ └─ Clean water, oils, chemicals, glycols

│

└─ NO → Contains solids/bubbles?

└─ YES → Doppler Technology

└─ Wastewater, slurries, aerated fluidsStep 3: Select Sensor Configuration

Based on pipe size and installation constraints:

Small Pipes (DN15-DN40 / DN50-DN65):

- Product: Ultrasonic Flow Meter for Small Pipes

- Sensors: TT02S (0°C ~ 65°C), TT03S (0°C ~ 115°C)

- Accuracy: ±2% (±1% after calibration)

- Applicable Fluid: Water, Oil, Chemical (single liquid medium without solid particles)

- Pipe Material: Metal/PVC, PP, PVDF rigid plastic pipe

- Application: Chemical dosing, oil transfer, HVAC systems

Medium to Large Pipes (DN25-DN1200):

- Product: Clamp-On Ultrasonic Flow Meter

- Sensors:

- TT01/TT02 (-40°C ~ +80°C)

- TT03 (-40°C ~ +130°C, high temp)

- TT02H (-40°C ~ +180°C, extreme high temp)

- Accuracy: ±1% of measured value

- Repeatability: 0.2%

- Application: Water distribution, industrial process, energy metering

Very Large Pipes (DN300+):

- Installation Type: Consider insertion-type (TT05) for cost savings

- Benefit: Single sensor vs. multiple acoustic paths

Step 4: Specify Optional Features

Temperature Compensation:

Add PT1000 RTD sensors if:

- Fluid temperature varies >10°C

- Measuring oils or chemicals

- BTU/energy measurement required

Communication:

- Modbus RS485: For SCADA integration

- 4-20mA: For simple PLC connection

- Pulse Output: For totalizing applications

Installation Best Practices for Optimal Fluid Compatibility

Pipe Material & Condition Requirements

Acceptable Pipe Materials:

- Metals: Carbon steel, stainless steel, copper, ductile iron

- Plastics: PVC, PP, PE, PVDF (rigid pipes only)

Critical Installation Mistakes We’ve Seen:

❌ WRONG: Installing on corroded pipe where thickness is unknown

✅ RIGHT: Measure actual pipe wall thickness with ultrasonic thickness gauge

❌ WRONG: Installing on pipe with internal liner of unknown material

✅ RIGHT: Verify liner material and thickness; may require special setup

❌ WRONG: Installing where internal deposits have accumulated

✅ RIGHT: Inspect or clean pipe before installation for ±1% accuracy

Sensor Positioning for Different Fluids

For Clean Fluids (Transit-Time):

- Horizontal pipes: Install sensors at 3 o’clock and 9 o’clock positions

- Avoid: 12 o’clock (gas trapping) and 6 o’clock (sediment accumulation)

For Dirty Fluids (Doppler):

- Vertical pipes: Upward flow preferred

- Horizontal pipes: Can install at 6 o’clock position to engage with settled particles

Straight Pipe Requirements:

To ensure accurate velocity profile:

- Upstream: Minimum 10D (10 × pipe diameter)

- Downstream: Minimum 5D

- Read more about pipe requirements

Troubleshooting Fluid-Related Measurement Issues

Problem 1: "No Signal" or Very Low Signal Strength

Possible Fluid-Related Causes:

- High gas content scattering ultrasonic signal

- Extreme temperature outside sensor rating

- Incorrect sound velocity for the fluid

- Heavy scaling or coating on pipe interior

Diagnostic Steps:

1. Check signal strength indicator (should be >50% for reliable measurement)

2. Verify fluid temperature is within sensor range

3. Confirm sound velocity setting matches actual fluid

4. Inspect pipe condition (ultrasonic thickness gauge)Solution from the Field:

On a glycol chiller line, we had perfect signal strength during commissioning but zero signal two weeks later. The issue? A 3°C temperature drop changed the glycol mixture from liquid to semi-solid (glycol concentration was incorrectly set at 60% instead of 40%). After correcting the glycol mix, the meter returned to normal operation.

Problem 2: Erratic or Unstable Readings

Fluid-Related Root Causes:

- Turbulence from nearby fittings/valves

- Two-phase flow (intermittent gas/liquid)

- Pulsating flow from reciprocating pump

- Changing fluid properties (temperature, composition)

Fixes:

- Relocate sensors to position with better straight run

- Add dampening in meter settings (trade-off: slower response)

- Install flow conditioner upstream

- Add pulsation dampener for pump pulsations

Problem 3: Readings Drift Over Time

Common Fluid-Induced Causes:

- Pipe scaling/coating changing acoustic path

- Sensor coupling gel degradation

- Temperature stratification in pipe

Preventive Maintenance:

- Annual verification: Compare against reference meter

- Coupling gel refresh: Every 2-3 years (or per manufacturer spec)

- Sensor relocation: If permanent coating develops

Fluid Compatibility: Transit-Time vs. Electromagnetic Flow Meters

Many engineers ask: "Should I use ultrasonic or electromagnetic flow meters?" The answer depends heavily on fluid properties:

| Factor | Ultrasonic (Transit-Time) | Electromagnetic |

|---|---|---|

| Fluid Conductivity | Not required | Must be >5 μS/cm |

| Suspended Solids | <2% preferred | Up to 30% OK |

| Installation | Non-invasive clamp-on | Inline (pipe cut required) |

| Pressure Drop | Zero | Zero |

| Pipe Material | Any | Non-magnetic (lined) |

| Cost (DN100) | $$ | $$$ |

| Maintenance | Minimal | Electrode cleaning |

When to Choose Ultrasonic:

- Non-conductive fluids (oils, pure water, deionized water)

- Existing pipes (retrofit without shutdown)

- Temporary measurement needs

- Budget constraints

When to Choose Electromagnetic:

- Highly contaminated fluids

- Abrasive slurries

- Need ±0.2% accuracy

- Learn more about EMF vs. Ultrasonic comparison

Frequently Asked Questions (FAQ)

1. Can ultrasonic flow meters measure steam?

No. Ultrasonic flow meters are designed for liquid measurement only. Steam (gas phase) has entirely different acoustic properties and very low density, making ultrasonic measurement impossible.

For steam measurement, use:

- Vortex flow meters (most common)

- Differential pressure flow meters (orifice plates)

2. What’s the minimum pipe size for ultrasonic flow meters?

Practical minimum: DN15 (1/2 inch) with specialized small-pipe sensors.

Our Small Pipe Ultrasonic Flow Meter series covers:

- DN15-DN40 (Popular type) and DN50-DN65 (Popular type)

- Accuracy: ±2% (±1% after calibration)

- Applicable Fluid: Water, Oil, Chemical (single liquid medium without solid particles or impurities)

- Pipe Material: Metal/PVC, PP, or PVDF rigid plastic pipe

- Applications: Chemical dosing, oil transfer, small HVAC loops

Below DN10, sensor size becomes a limiting factor. Consider alternative technologies like turbine meters.

3. Can I measure drinking water with ultrasonic meters?

Absolutely yes. Potable water is one of the ideal fluids for ultrasonic flow measurement.

Advantages for drinking water:

- Hygienic: Clamp-on installation = zero contamination risk

- No pressure drop: No flow restriction

- Bi-directional: Detects backflow

- No moving parts: No wear or failure

- NSF/ANSI 61 compliant (wetted sensors)

Many water utilities use portable ultrasonic meters for leak detection and meter verification programs.

4. How do I know if my fluid is too viscous for ultrasonic measurement?

Rule of thumb:

- <100 cSt (centistokes): ✅ Excellent compatibility

- 100-500 cSt: ⚠️ Possible with temperature compensation

- 500-1000 cSt: ⚠️ Challenging; test before committing

- >1000 cSt: ❌ Not recommended

Viscosity Effects:

- Signal attenuation: High viscosity absorbs ultrasonic energy

- Flow profile change: Laminar flow creates velocity profile errors (see Reynolds Number impact on flow measurement)

- Temperature sensitivity: Viscosity can change 50%+ with temperature

Test Protocol:

If your fluid is 200-1000 cSt, request a field trial from the manufacturer with your actual fluid and operating conditions.

5. What concentration of suspended solids is too much for transit-time meters?

Critical thresholds:

- <1% solids: ✅ Excellent for transit-time

- 1-2% solids: ⚠️ Marginal; depends on particle size

- 2-5% solids: ❌ Transit-time unreliable; use Doppler

- >5% solids: ✅ Ideal for Doppler technology

Particle Size Matters:

Fine particles (<10 microns) cause less signal scattering than large particles. A fluid with 3% fine clay particles might work where 1% sand particles fails.

Field Decision Tool:

If you can see through your fluid in a glass sample jar, transit-time will likely work. If opaque or cloudy, consider Doppler.

6. Can ultrasonic meters handle temperature cycling?

Standard sensor ratings (per Company Product Catalog):

- TT02S (small pipe): 0°C to +65°C

- TT03S (small pipe, high temp): 0°C to +115°C

- TT01/TT02 (standard clamp-on): -40°C to +80°C

- TT03 (high temp): -40°C to +130°C

- TT02H (extreme high temp): -40°C to +180°C

Temperature Cycling Challenges:

- Thermal expansion changes pipe dimensions

- Coupling gel degradation at temperature extremes

- Sound velocity changes require compensation

Best Practice: If your process cycles >50°C regularly, specify:

- High-temperature sensors

- Automatic temperature compensation

- High-temp coupling compound

- Annual recalibration

7. How accurate are ultrasonic meters on slurries compared to clean water?

Accuracy Comparison:

| Fluid Type | Transit-Time | Doppler |

|---|---|---|

| Clean Water | ±0.5-1% | ±1-2% |

| Light Slurry (<5% solids) | Not recommended | ±2-3% |

| Heavy Slurry (5-20% solids) | Not possible | ±3-5% |

Why Lower Accuracy on Slurries:

- Doppler measures particle velocity, not bulk fluid velocity

- Velocity profile variations increase with solid content

- Settling or stratification creates measurement errors

When Slurry Accuracy Matters:

For custody transfer or process control requiring ±1%, consider:

- Electromagnetic flow meters (±0.5% on slurries)

- Coriolis meters (±0.1%, but expensive and limited size range)

Key Takeaways: Choosing the Right Fluid for Ultrasonic Measurement

✅ IDEAL Fluids (Transit-Time):

- Clean water (municipal, process, drinking)

- Industrial oils and lubricants

- Clean chemical solutions

- Glycol mixtures

- HVAC chilled/hot water

✅ GOOD Fluids (Doppler Technology):

- Wastewater and sewage

- Slurries (<40% solids)

- Aerated liquids (moderate gas content)

- Dirty water with suspended particles

❌ AVOID (Use Alternative Technology):

- Steam and gases

- High-viscosity fluids (>1000 cSt)

- Multi-phase flows

- Highly aerated fluids (>5% gas content)

- Pure light hydrocarbons (acoustic impedance issues)

🎯 Selection Strategy:

- Start with fluid characterization (solids, viscosity, temperature)

- Match to correct technology (transit-time vs. Doppler)

- Consider installation constraints (clamp-on vs. inline)

- Factor in accuracy requirements vs. cost

- When in doubt, request a field trial with your actual fluid

Ready to Specify Your Ultrasonic Flow Meter?

Choosing the right ultrasonic flow meter for your specific fluid doesn’t have to be complicated. At Soaring Instrument, we’ve installed ultrasonic flow meters on everything from aggressive acids to mining slurries across diverse industries.

Our Product Range:

- Clamp-On Ultrasonic Flow Meters (DN25-DN1200)

- Small Pipe Ultrasonic Meters (DN15-DN40)

- Portable Ultrasonic Flow Meters for troubleshooting and verification

- Energy/BTU Meters with temperature compensation

Get Expert Application Support:

Our engineers will help you:

✓ Characterize your fluid properties

✓ Select the optimal sensor configuration

✓ Specify temperature compensation if needed

✓ Provide sound velocity data for your specific chemical

✓ Recommend installation location and pipe requirements

Contact our technical team today →

Email: [email protected]

Phone: +86-21-57652429

WhatsApp: +86-13585991410

Related Articles

Flow Measurement Technology:

- The Complete Guide of Ultrasonic Flow Meter

- How Does an Ultrasonic Flow Meter Work: Understanding the Technology

- Transit-Time vs. Doppler: Which Should You Choose?

Application Guides:

- Why Choose Ultrasonic Flow Meters for Wastewater Treatment?

- Small Pipe Applications: Precision Matters

- Chemical Industry Flow Measurement Solutions

Troubleshooting:

- Why Is My Ultrasonic Flow Meter Not Working? Expert Solutions

- How to Troubleshoot Ultrasonic Flow Meter Signal Loss

Comparison Guides:

- Ultrasonic vs. Electromagnetic: Which Flow Meter Technology?

- EMF vs. Ultrasonic vs. Coriolis: Which Wins for Your Industry?