Selecting the wrong flow measurement device can lead to costly errors, wasted resources, and process inefficiencies.

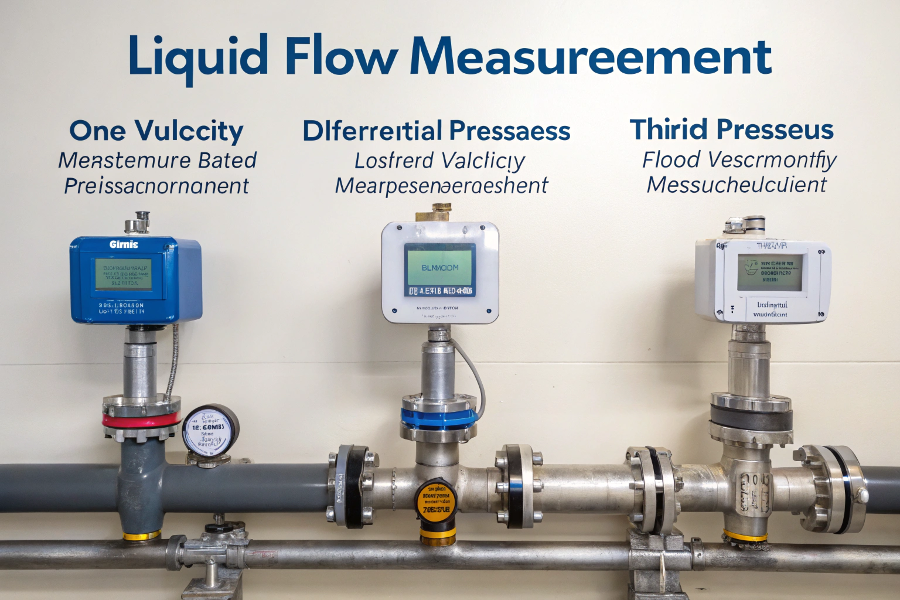

A variety of devices measure liquid flow, including differential pressure meters, turbine meters, magnetic flowmeters, ultrasonic meters, and Coriolis meters, each suited for specific applications.

Common Flow Measurement Devices

Let me share my experience to help you choose the right flow measurement device for your needs.

What Device is Used to Measure Liquid Flow?

Many engineers struggle with selecting the right flow measurement technology.

Common liquid flow measurement devices include orifice plates, venturi meters, electromagnetic flowmeters, ultrasonic meters, and Coriolis mass flowmeters.

Liquid Flow Measurement Technologies

From my field experience:

Device Comparison

Technology Overview

Device Type Accuracy Cost Applications Differential Pressure ±2% Low General purpose Magnetic ±0.5% Medium Conductive liquids Ultrasonic ±1% High Clean liquids Coriolis ±0.1% Very high Mass flow Key Features

- Installation requirements

- Maintenance needs

- Accuracy specifications

- Cost considerations

Selection Criteria

Application Factors

- Fluid properties

- Flow conditions

- Accuracy needs

- Budget limits

Operational Aspects

- Installation ease

- Maintenance requirements

- Performance monitoring

- Calibration needs

How Do You Measure the Flow of a Liquid?

Understanding measurement principles helps choose the right technology.

Liquid flow can be measured using velocity-based, differential pressure, or mass flow principles, depending on the application requirements.

Flow Measurement Methods

Based on my measurement expertise:

Measurement Techniques

Basic Methods

Method Principle Best For Velocity Direct speed Clean liquids Differential Pressure drop General use Mass flow Direct mass Precision Volume Direct volume Billing Application Considerations

- Flow conditions

- Accuracy needs

- Installation limits

- Maintenance capabilities

Implementation Guide

System Design

- Requirements analysis

- Technology selection

- Installation planning

- Performance verification

Operational Planning

- Startup procedures

- Monitoring systems

- Maintenance schedules

- Calibration plans

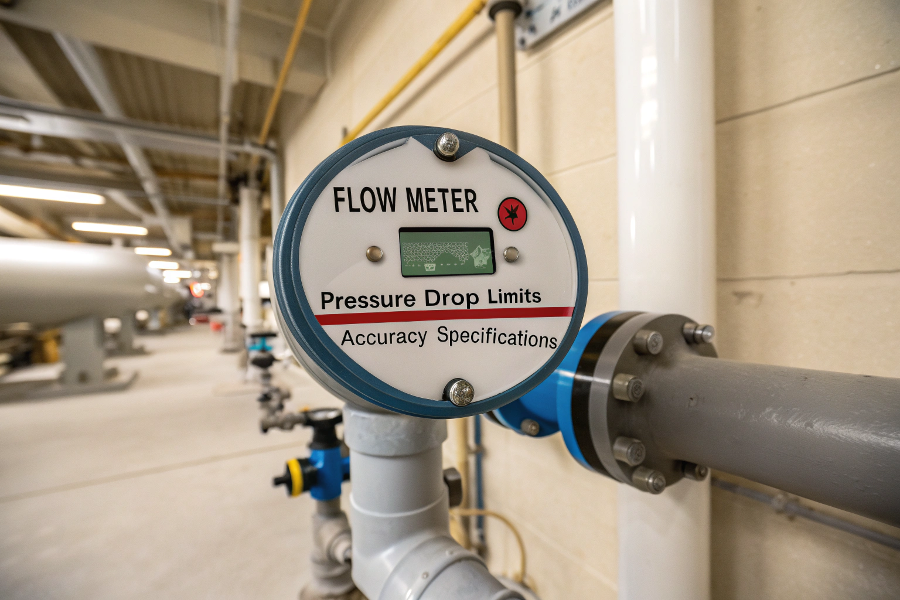

How to Select a Water Flow Meter?

Choosing the wrong water meter leads to measurement errors and wasted resources.

Select a water flow meter based on flow range, pressure drop limits, accuracy requirements, and installation conditions.

Water Flow Meter Selection Guide

Drawing from my selection experience:

Selection Process

Key Considerations

Factor Impact Importance Flow range Accuracy High Pressure drop Energy cost Medium Installation Performance High Cost Budget Medium Technical Requirements

- Accuracy needs

- Pressure limits

- Temperature range

- Installation space

Application Guidelines

Design Phase

- Requirements review

- Technology selection

- Size calculation

- Cost analysis

Implementation

- Installation planning

- Performance testing

- Maintenance scheduling

- Staff training

What Instrument is Used to Measure the Flow of Water?

Different water applications require specific measurement solutions.

Common water flow instruments include turbine meters, electromagnetic flowmeters, ultrasonic meters, and mechanical meters.

Water Flow Measurement Instruments

Based on my application experience:

Instrument Types

Common Technologies

Type Application Benefits Turbine Clean water Low cost Magnetic Process water No moving parts Ultrasonic Large pipes Non-intrusive Mechanical Billing Simple design Selection Factors

- Water quality

- Flow conditions

- Accuracy needs

- Maintenance requirements

Implementation Strategy

Planning Phase

- Application review

- Technology selection

- Installation design

- Performance criteria

Execution Phase

- Installation guidelines

- Testing procedures

- Maintenance plans

- Performance monitoring

Conclusion

Successful liquid flow measurement requires careful consideration of application requirements, proper device selection, and appropriate implementation strategies.