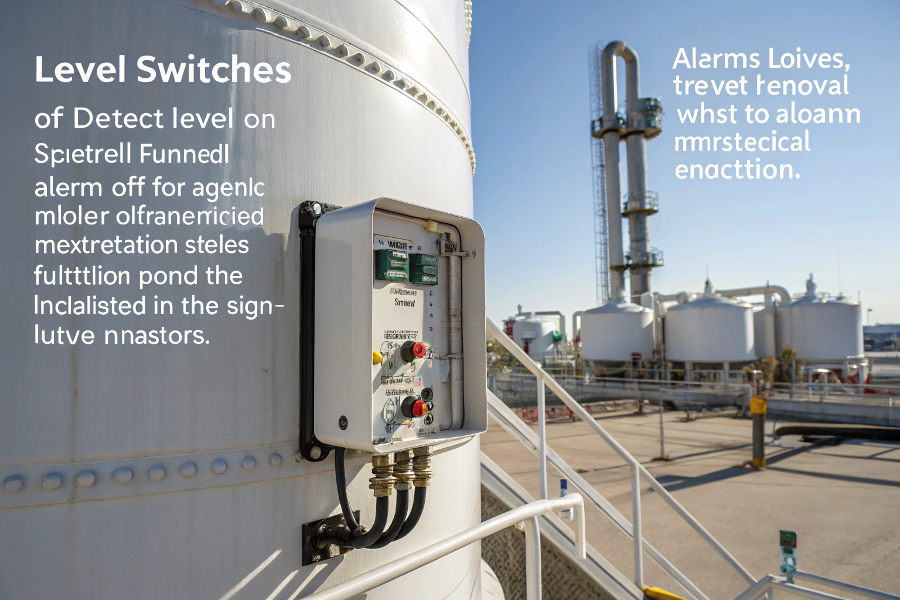

Misunderstanding level switch principles can lead to incorrect installation, false readings, and potential system failures.

Level switches operate on various physical principles including buoyancy, conductivity, vibration, or capacitance to detect material presence at specific points and provide binary output signals.

Level Switch Working Principles Overview

Let me share insights from my extensive experience with level measurement technologies.

What is the Primary Function of a Level Switch?

Many users underestimate the critical role of level switches in process safety and control.

Level switches primarily function as point-level detection devices, providing on/off signals for alarm, control, or safety functions when material reaches specific levels.

Level Switch Functions

From my field applications experience:

Core Functions

Primary Applications

Function Purpose Example Use Overfill Protection Safety High-level alarm Pump Protection Equipment safety Low-level cutoff Process Control Automation Fill control Interface Detection Separation Oil/water interface Critical Features

- Reliable detection

- Fast response

- Fail-safe operation

- Simple maintenance

Implementation Aspects

Safety Considerations

- Redundancy needs

- Failure modes

- Response time

- Regular testing

Control Integration

- Signal interface

- Alarm systems

- Interlock functions

- Documentation

These functions ensure system reliability.

What is the Difference Between a Level Transmitter and a Level Switch?

Understanding this distinction is crucial for proper instrument selection and application.

Level switches provide discrete (on/off) signals at specific points, while transmitters continuously measure and output actual level values across their measurement range.

Level Switch vs Transmitter Comparison

Based on my system design experience:

Key Differences

Operational Characteristics

Feature Switch Transmitter Output Type Binary Continuous Measurement Point level Full range Complexity Simple Advanced Cost Lower Higher Application Considerations

- Process requirements

- Control strategy

- Safety needs

- Budget constraints

Selection Criteria

Process Factors

- Material properties

- Operating conditions

- Accuracy needs

- Maintenance access

System Integration

- Control system compatibility

- Power requirements

- Signal processing

- Installation complexity

These factors guide proper selection.

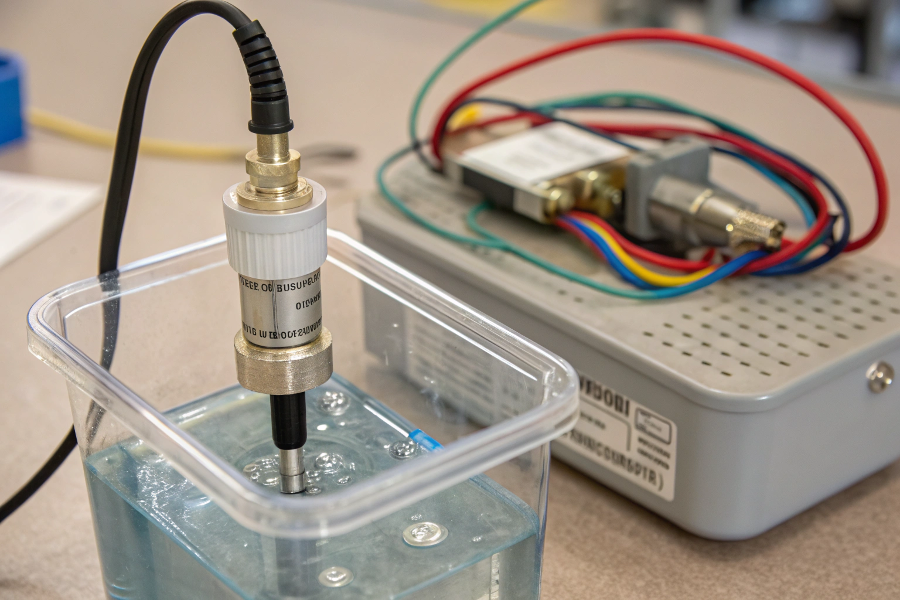

How Does a Conductive Level Switch Work?

Conductive level switches are often misunderstood, leading to application errors in conductive liquids.

Conductive level switches operate by detecting electrical conductivity between electrodes when conductive liquid creates a circuit path, triggering the switch output.

Conductive Level Switch Operation

Drawing from my installation experience:

Operating Principles

Key Components

Component Function Consideration Electrodes Contact points Material compatibility Electronics Signal processing Sensitivity adjustment Housing Protection Environmental rating Connection Process interface Installation method Detection Method

- Conductivity measurement

- Reference electrode

- Switching threshold

- Time delay

Application Guidelines

Material Requirements

- Minimum conductivity

- Chemical compatibility

- Temperature limits

- Pressure rating

Installation Factors

- Electrode length

- Mounting position

- Cable routing

- Maintenance access

These principles ensure proper operation.

What is the Working Principle of Level?

Level measurement principles vary significantly based on technology and application needs.

Level measurement operates on various physical principles including hydrostatic pressure, buoyancy, electrical properties, or wave propagation to detect material presence or quantity.

Level Measurement Principles

From my technical expertise:

Measurement Principles

Common Technologies

Technology Principle Best Application Float Buoyancy Clean liquids Vibrating Frequency change Bulk solids Capacitive Dielectric Interface Ultrasonic Sound waves Non-contact Physical Properties

- Material density

- Dielectric constant

- Conductivity

- Surface conditions

Implementation Strategy

Selection Criteria

- Process conditions

- Material properties

- Accuracy requirements

- Environmental factors

Performance Factors

- Response time

- Resolution

- Reliability

- Maintenance needs

These principles guide proper application.

Conclusion

Understanding level switch working principles is essential for selecting the right technology and ensuring reliable operation in your specific application.