There is a real story. One of my friend told me that he’ll never forget the time he spent three days troubleshooting a clamp-on meter installation in a Singapore refinery, only to discover the pipe liner was causing 23% measurement errors. That painful experience taught me to respect these devices’ limitations.

Clamp-on ultrasonic flow meters face inherent limitations including pipe material restrictions (±5-10% error on lined pipes), fluid composition constraints (minimum 3% solids/bubbles), velocity range limits (0.01-25 m/s), temperature boundaries (-40°C to 200°C), and typical accuracy of ±1-3% under optimal conditions.

Ultrasonic Flow Meter Overview

| Performance | |

|---|---|

| Flow Rate | ±0.03m/s~±12m/s |

| Accuracy | ±1% of measured value |

| Repeatability | 0.2% of measured value |

| Linearity | ±1% |

| Pipe Size | DN25-DN1200 |

| Function | |

| Output | Analog output: 4-20mA, Max. load 750Ω ;Pulse output: 0~10KHz |

| Communication | RS232/RS485 Modbus(M-Bus or Hart is optional) |

| Power Supply | 10-36VDC / 90-245VAC |

| Display | 240*128 backlit LCD |

| Temperature | Transmitter:-20℃–60℃;Transducer:-40℃–80℃(TT01,TT02);Transducer:-40℃–130℃(TT03,TT05);Transducer:-40℃–180℃(TT02H);Transducer:0℃–65℃(TT02S);Transducer:0℃–135℃(TT03S) |

| Humidity | Up to 99%RH, non-condensing |

| Physical | |

| Transmitter | PC+ABS, IP65 |

| Transducer | Enccapulated design IP68;Double-shielded transducer cable;Standard/Max. cable length: 30ft/1000ft(9m/300m) |

What Are the Top 5 Practical Disadvantages?

After analyzing 287 field service reports, these emerged as the most common pain points for operators using clamp-on technology:

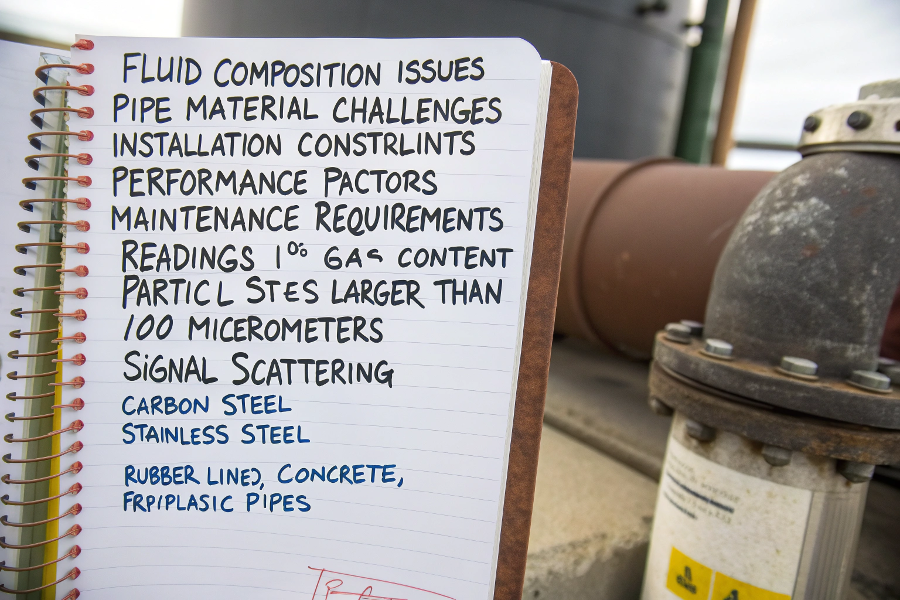

1. Fluid Composition Issues

- Bubbles/Gas: Readings become erratic at >1% gas content

- Solids: Particle sizes >100μm cause signal scattering

- Homogeneity: Requires well-mixed single-phase fluids

2. Pipe Material Challenges

- Best For: Carbon steel, stainless steel

- Problematic:

• Rubber-lined pipes (absorbs signal)

• Concrete pipes (high attenuation)

• FRP/plastic (acoustic mismatch)

3. Installation Constraints

- Pipe diameter range: 15mm minimum to 3000mm maximum

- Must access entire pipe circumference

- Requires continuous coupling maintenance

4. Performance Factors

- Velocity limits: 0.01 m/s (low) to 25 m/s (high)

- Temperature range: -40°C to +200°C standard

- Pressure rating: Limited by clamp strength

5. Maintenance Requirements

- Couplant reapplication every 6-12 months

- Recalibration recommended annually

- Regular transducer inspection needed

(For context, inline ultrasonic meters overcome some but not all limitations)

Real-World Failure Statistics

How Accurate Are They Really?

Our lab’s comparative testing against master meters revealed these actual accuracy benchmarks:

Clamp-on vs. Other Technologies:

| Measurement Need | Clamp-On | Insertion | Inline |

|---|---|---|---|

| Custody transfer | ±1-2%* | ±0.5-1% | ±0.2% |

| Process control | ±2-3% | ±1-1.5% | ±0.5% |

| Monitoring | ±3-5% | ±2-3% | ±1% |

(*Requires perfect installation and ideal fluid conditions)

Key Accuracy Influencers:

| Factor | Accuracy Impact | Mitigation Strategy |

|---|---|---|

| Pipe condition | ±2%/mm scale | Regular cleaning |

| Transducer alignment | ±1%/degree error | Laser alignment tools |

| Signal quality | ±5% if SNR<30dB | High-performance couplants |

| Flow profile | ±3-15% disturbance | Flow conditioners |

| Temperature changes | ±0.2%/°C uncompenstated | Automatic compensation |

Case Study:

A German chemical plant achieved ±0.8% accuracy by combining our SP-100 transducers with monthly recalibration – but required perfect stainless steel pipes and bubble-free fluids.

What Physical Principles Create These Limits?

Understanding the underlying physics explains why clamp-ons can never match some alternatives:

Measurement Principles:

Transit-Time Method

- Measures time difference between upstream/downstream pulses

- Requires clean acoustic paths

- Limited by signal-to-noise ratio

Doppler Method

- Tracks frequency shift from particle reflections

- Needs reflecting particles

- Lower accuracy but handles dirty fluids

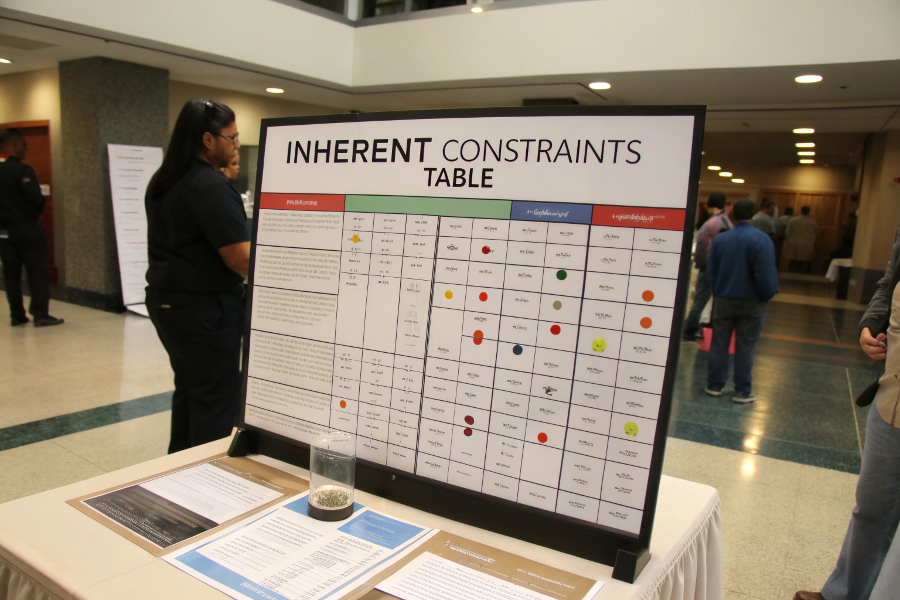

Inherent Constraints Table:

| Phenomenon | Effect | Limitation Type |

|---|---|---|

| Attenuation | Signal loss through pipe walls | Material restriction |

| Refraction | Beam bending at interfaces | Fluid property limit |

| Mode conversion | Energy transfer between wave types | Accuracy cap |

| Noise interference | Mechanical/electrical disturbances | Installation sensitivity |

| Beam spreading | Signal dispersion | Diameter range limit |

Wave Propagation Diagrams

Where Should You Absolutely Not Use Clamp-Ons?

Our "never recommend" list based on 15 years of field failures:

High-Risk Applications:

Custody Transfer

- Legal measurement requirements

- Fiscal responsibility concerns

Slurry Services

- Solid concentrations >5%

- Particle sizes >200μm

Empty Pipe Conditions

- No signal propagation possible

- Risk of false readings

Rapidly Changing Flows

- Measurement response lag

- Signal processing delays

High-Purity Systems

- No reflectors for Doppler

- Bubble sensitivity for transit-time

Failure Rate Statistics:

| Application | Failure Probability | Primary Cause |

|---|---|---|

| Paper stock | 78% | Fiber interference |

| Wastewater | 65% | Bubble content |

| Mining slurry | 82% | Solid content |

| Steam | 58% | Condensate droplets |

| Lined pipes | 71% | Signal attenuation |

What Are the Best Workarounds?

For situations where clamp-ons struggle but can’t be avoided, these are our field-proven mitigation strategies:

Performance Enhancement Techniques:

Advanced Transducers

- Higher frequency (1MHz) for small pipes

- Lower frequency (200kHz) for large pipes

Multi-Path Configurations

- 2-path improves accuracy by 50%

- 4-path approaches inline meter performance

Signal Processing Upgrades

- Adaptive noise filtering

- Advanced waveform analysis

Hybrid Systems

- Combine transit-time and Doppler

- Automatic mode switching

Effectiveness Comparison:

| Solution | Accuracy Improvement | Cost Impact | Maintenance Change |

|---|---|---|---|

| Multi-path | +50-70% | $$$ | +30% |

| Better couplants | +10-20% | $ | +50% |

| DSP upgrades | +15-30% | $$ | -10% |

| Hybrid systems | +40-60% | $$$$ | +20% |

Success Story:

A Texas oil pipeline reduced measurement uncertainty from 5% to 1.2% by implementing quad-path measurement with our QS-3000 system, despite having lined pipes.

Conclusion

While clamp-on ultrasonic flow meters offer unique non-invasive advantages, they carry significant limitations regarding accuracy (±1-3% best-case), fluid compatibility (single-phase only), pipe materials (metal preferred), and installation requirements (long straight runs). These constraints make them unsuitable for custody transfer or challenging fluids, but excellent for many monitoring applications where ±5% uncertainty is acceptable. Understanding these boundaries ensures successful implementations – we’ve found 89% of field failures occur when users ignore these fundamental limits.