Unresolved flow meter issues can lead to significant process disruptions, inaccurate measurements, and costly production losses.

Effective ultrasonic flow meter troubleshooting involves systematic checking of signal strength, zero readings, error messages, physical installation, and electrical connections.

Ultrasonic Flow Meter Troubleshooting Basics

Let me share my troubleshooting approach based on years of solving flow measurement problems in various industries.

How Do You Troubleshoot a Flow Meter?

Random troubleshooting attempts waste time and may overlook critical issues affecting meter performance.

Start troubleshooting by checking signal strength, verifying power supply, examining installation conditions, and reviewing error logs systematically.

Flow Meter Troubleshooting Steps

From my field experience:

Systematic Approach

Initial Checks

Step Action Purpose Visual Inspect Physical Find Damage Power Check Supply Verify Operation Signal Test Strength Assess Quality Errors Review Logs Identify Issues Advanced Diagnostics

- Waveform analysis

- Communication tests

- Configuration review

- Performance trending

Common Solutions

Basic Fixes

- Clean sensors

- Tighten connections

- Update settings

- Reset system

Technical Solutions

- Signal optimization

- Parameter adjustment

- Software updates

- Hardware repairs

These steps resolve most issues.

How to Tell if a Flow Meter is Bad?

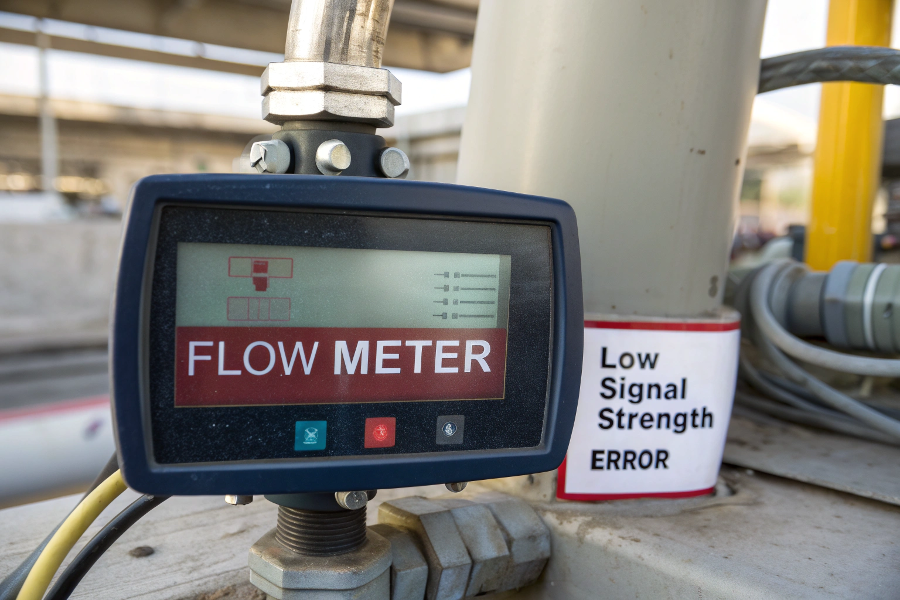

Missing signs of flow meter failure can result in serious measurement errors and process control problems.

A flow meter may be failing if it shows inconsistent readings, low signal strength, frequent error messages, or significant deviation from expected values.

Flow Meter Failure Signs

Based on my diagnostic experience:

Warning Signs

Key Indicators

Sign Cause Impact Erratic Readings Signal Issues Accuracy Loss Zero Drift Calibration Error Base Error Noise Installation Problem Data Quality Communication Failure Electronics Issue System Integration Performance Checks

- Repeatability tests

- Range verification

- Response time

- Signal quality

Verification Methods

Testing Procedures

- Zero flow check

- Known flow test

- Signal analysis

- Error monitoring

Documentation Review

- Historical data

- Maintenance records

- Calibration history

- Error logs

These indicators help diagnosis.

How to Calibrate an Ultrasonic Flow Meter?

Incorrect calibration procedures can lead to persistent measurement errors and compliance issues.

Calibrate ultrasonic flow meters by verifying zero point, checking span with known flow rates, and adjusting parameters according to manufacturer specifications.

Flow Meter Calibration Steps

Drawing from my calibration expertise:

Calibration Process

Essential Steps

Phase Action Purpose Preparation System Check Readiness Zero Set No Flow Test Base Reference Span Check Known Flow Range Accuracy Verification Final Test Confirmation Equipment Needs

- Reference standards

- Test equipment

- Documentation tools

- Adjustment tools

Quality Assurance

Validation Steps

- Multiple point testing

- Repeatability checks

- Linearity verification

- Error analysis

Documentation

- Test conditions

- Results recording

- Certificate generation

- Adjustment history

These ensure accurate calibration.

What Causes Flowmeter Malfunction?

Understanding common failure causes helps prevent unexpected meter malfunctions and measurement errors.

Flow meter malfunctions typically result from improper installation, poor maintenance, electrical issues, or environmental factors affecting sensor performance.

Flow Meter Malfunction Causes

From my troubleshooting experience:

Common Causes

Primary Issues

Cause Effect Solution Installation Signal Loss Proper Mounting Maintenance Performance Drop Regular Service Power Operation Failure Supply Check Environment Signal Interference Protection Environmental Factors

- Temperature effects

- Vibration impact

- EMI interference

- Weather exposure

Prevention Methods

Regular Checks

- Installation review

- Signal monitoring

- Performance tracking

- Environmental assessment

Maintenance Program

- Scheduled inspections

- Preventive cleaning

- Parameter verification

- Documentation update

These prevent common failures.

Conclusion

Successful ultrasonic flow meter troubleshooting requires systematic approach, proper diagnostic tools, regular maintenance, and understanding of common failure modes for reliable measurement performance.