Choosing the wrong type of level switch can lead to costly system failures, maintenance issues, and safety risks.

Level switches come in various types including float, vibrating fork, capacitive, ultrasonic, and optical technologies, each designed for specific applications and operating conditions.

Types of Level Switches

Let me share my experience in selecting and implementing different level switch technologies.

What Are the Different Types of Level Sensors?

Many industry professionals struggle to choose the right level sensor for their specific needs.

Level sensors can be categorized into contact and non-contact types, with technologies ranging from mechanical float switches to advanced radar and ultrasonic systems.

Level Sensor Categories

Based on my field experience:

Contact Type Sensors

Mechanical Types

Technology Operation Best Application Float Buoyancy General liquids Displacer Weight change Interface detection Magnetic Reed switch Clean liquids Conductivity Electrical Conductive liquids Electronic Types

Technology Operation Best Application Capacitive Dielectric Various materials Vibrating Frequency Powders/liquids Thermal Heat transfer Critical points Optical Light reflection Clean liquids

Non-Contact Sensors

Common Technologies

- Ultrasonic sensors

- Radar systems

- Laser devices

- Nuclear methods

Selection Factors

- Process conditions

- Material properties

- Installation requirements

- Maintenance needs

These options provide solutions for various applications.

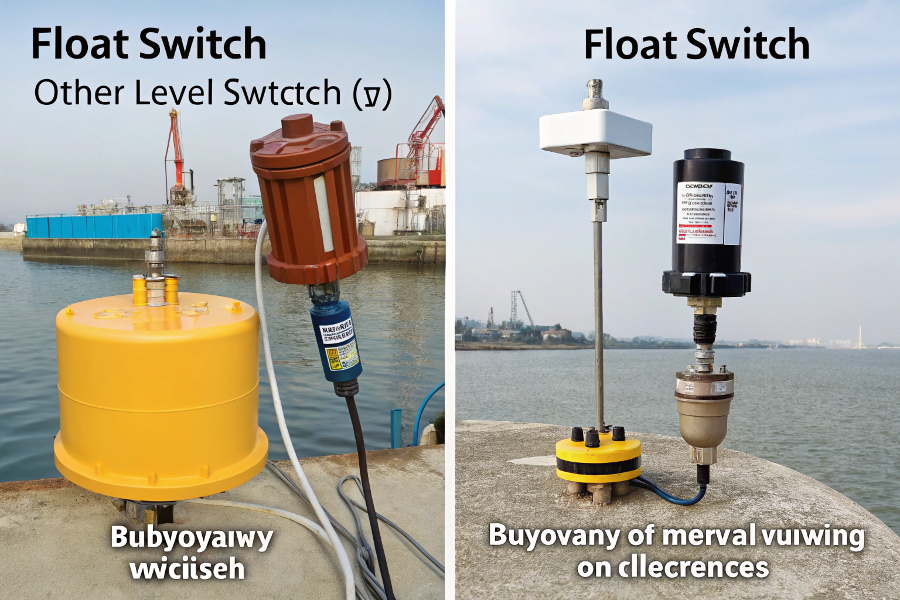

Is a Float Switch the Same as a Level Switch?

This common question reveals a fundamental misunderstanding of level detection technologies.

A float switch is just one type of level switch that uses buoyancy, while level switches encompass many different technologies for detecting material levels.

Float Switch vs Level Switch

Drawing from my technical expertise:

Key Differences

Operational Principles

Aspect Float Switch General Level Switch Method Mechanical Various Moving Parts Yes Depends on type Maintenance Regular Varies Cost Lower Technology dependent Application Considerations

- Process requirements

- Environmental conditions

- Reliability needs

- Budget constraints

Selection Guidelines

Technology Benefits

- Application suitability

- Installation ease

- Maintenance needs

- Life cycle costs

Implementation Factors

- Training requirements

- Spare parts availability

- Support needs

- Future upgrades

These factors guide proper selection.

What Are the Different Types of Level Transmitters?

Understanding level transmitter types is crucial for accurate continuous level measurement.

Level transmitters provide continuous level measurement using various technologies like pressure, radar, ultrasonic, and guided wave radar, each suited for specific applications.

Level Transmitter Technologies

From my system design experience:

Transmitter Technologies

Common Types

Technology Principle Best Use Pressure Hydrostatic Liquids Radar Microwave Bulk solids Ultrasonic Sound waves Open tanks Guided Wave TDR Interface Selection Criteria

- Process conditions

- Material properties

- Accuracy needs

- Installation constraints

Implementation Strategy

System Integration

- Signal output types

- Communication protocols

- Control system interface

- Data logging needs

Operational Requirements

- Calibration methods

- Maintenance procedures

- Troubleshooting

- Documentation

These considerations ensure successful implementation.

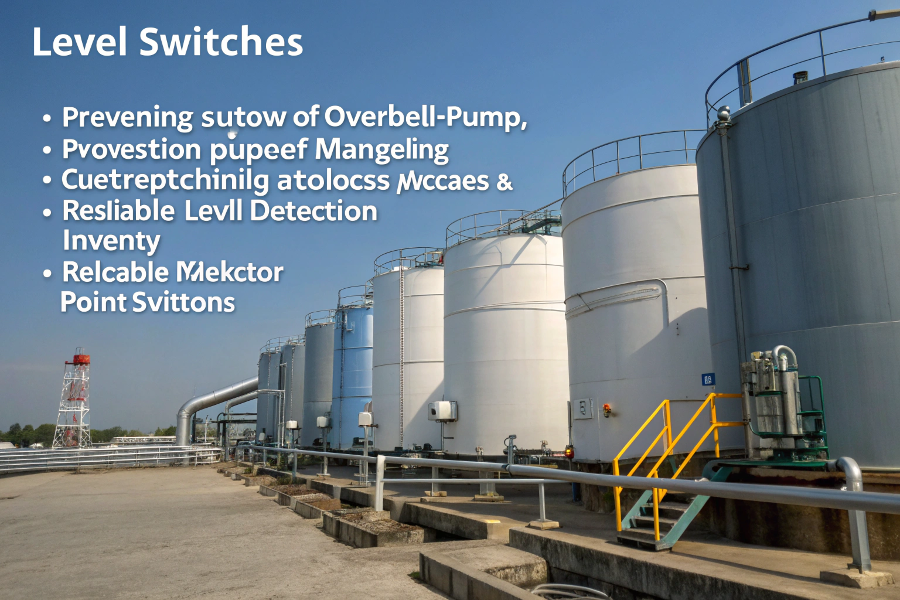

What is the Purpose of a Level Switch?

Many users don’t fully understand the critical roles level switches play in process control and safety.

Level switches serve multiple purposes including overflow prevention, pump protection, process control, and inventory management through reliable point-level detection.

Level Switch Applications

Based on my installation experience:

Primary Functions

Safety Applications

Function Purpose Benefit High Level Overflow prevention Safety Low Level Equipment protection Reliability Interface Product separation Quality Emergency System shutdown Risk reduction Control Applications

- Process automation

- Batch control

- Inventory management

- Transfer operations

Implementation Requirements

System Design

- Safety integration

- Control strategy

- Alarm management

- Redundancy needs

Operational Support

- Regular testing

- Maintenance schedules

- Training programs

- Documentation

These functions ensure safe and efficient operation.

Conclusion

Selecting the right level switch type requires careful consideration of process conditions, material properties, and operational requirements to ensure reliable performance and safety compliance.