Plant engineers often struggle to choose between inline and clamp-on ultrasonic flow meters for their applications.

The main difference lies in their installation method: inline meters require pipe cutting and direct fluid contact, while clamp-on meters mount externally without process interruption.

Clamp-on Ultrasonic Flow Meters

Let me share my experience with both types to help you make an informed decision.

What Are the Two Types of Ultrasonic Flow Meters?

Many customers ask me about the fundamental differences between ultrasonic flow meter types.

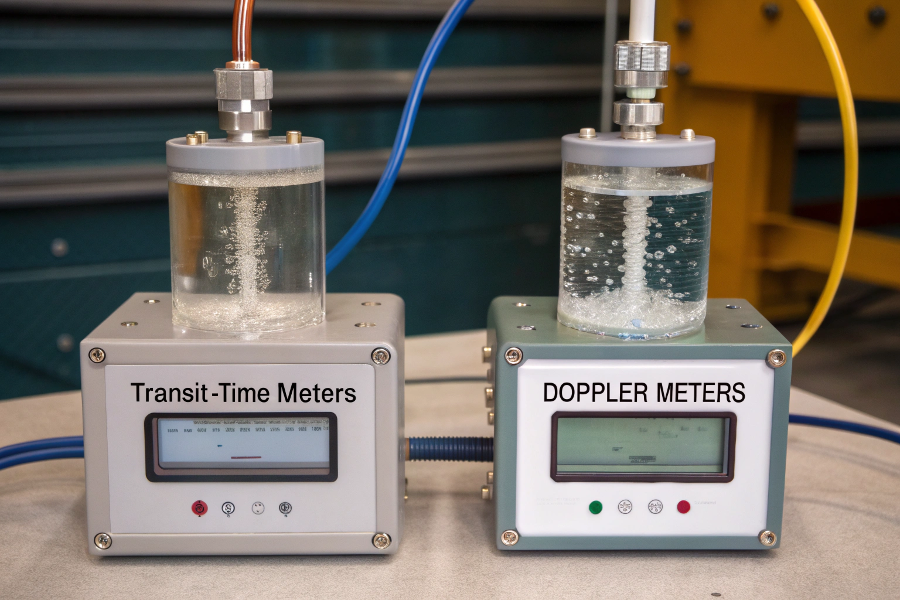

The two main types are transit-time and Doppler ultrasonic flow meters, each using different principles to measure flow and suited for different applications.

Transit-time vs Doppler Measurement

From my years of field experience:

Transit-Time Technology

Operating Principle

Feature Description Application Signal Path Direct transmission Clean liquids Measurement Time difference Accurate flow Installation Both inline/clamp-on Flexible use Accuracy High precision Billing/custody Key Characteristics

- Works with clean fluids

- High accuracy rates

- Bi-directional measurement

- Multiple configurations

Doppler Technology

Operating Features

Aspect Details Usage Signal Frequency shift Dirty fluids Particles Required Slurries Setup Usually clamp-on Non-invasive Performance Flow indication Process monitoring Application Areas

- Wastewater treatment

- Mining slurries

- Paper pulp

- Chemical processing

What is a Clamp-On Ultrasonic Flow Meter?

Process engineers frequently need flow measurement solutions without system interruption.

A clamp-on ultrasonic flow meter is an external device that measures flow rate through pipe walls using ultrasonic signals, requiring no pipe modifications or process downtime.

Clamp-on Installation Method

Based on my installation experience:

Installation Aspects

Mounting Requirements

Element Consideration Benefit Location Straight run Accuracy Surface Clean, smooth Signal quality Access Maintenance space Serviceability Environment Protection Reliability Setup Procedures

- Site preparation

- Transducer positioning

- Signal optimization

- System validation

Operational Features

Key Benefits

- Non-invasive measurement

- Zero pressure drop

- Easy maintenance

- Portable options

Application Areas

- HVAC systems

- Process monitoring

- Energy measurement

- Temporary installations

What is an Inline Flow Meter?

Plant operators often need permanent, high-accuracy flow measurement solutions.

An inline ultrasonic flow meter is a device installed directly into the pipeline, requiring pipe cutting and system shutdown during installation but offering superior accuracy and reliability.

Drawing from my system design experience:

Installation Considerations

Physical Requirements

Factor Impact Consideration Pipe modification System downtime Planning Flanges/threads Connection type Standards Space Access requirements Layout Orientation Flow direction Positioning Integration Aspects

- Piping modifications

- Support structures

- Power supply

- Signal connections

Performance Characteristics

Operational Benefits

- Higher accuracy

- Better repeatability

- Known geometry

- Calibration certainty

Application Areas

- Custody transfer

- Critical processes

- High-accuracy needs

- Permanent installations

What Are the Disadvantages of Clamp-On Ultrasonic Flow Meters?

Users need to understand limitations before selecting clamp-on technology.

Main disadvantages include sensitivity to pipe conditions, lower accuracy compared to inline meters, and limitations with certain fluid types and pipe materials.

Clamp-on Meter Installation

Based on my troubleshooting experience:

Technical Limitations

Performance Issues

Limitation Impact Mitigation Pipe condition Signal quality Surface prep Fluid properties Measurement accuracy Proper setup Installation Signal strength Expert guidance Environment Reliability Protection Application Constraints

- Material compatibility

- Temperature limits

- Flow profile effects

- Signal penetration

Operational Challenges

Maintenance Requirements

- Regular validation

- Signal checking

- Parameter updates

- Surface cleaning

Installation Factors

- Expertise needed

- Site preparation

- Environmental protection

- Access requirements

Conclusion

Both inline and clamp-on ultrasonic flow meters have their place in industrial applications, with selection depending on accuracy requirements, installation constraints, and operational needs.