Building managers and facility engineers often face challenges in accurately measuring energy consumption and flow rates in HVAC systems.

Clamp-on ultrasonic BTU meters are non-invasive energy measurement devices that combine ultrasonic flow measurement with temperature sensing to calculate thermal energy consumption in heating and cooling systems.

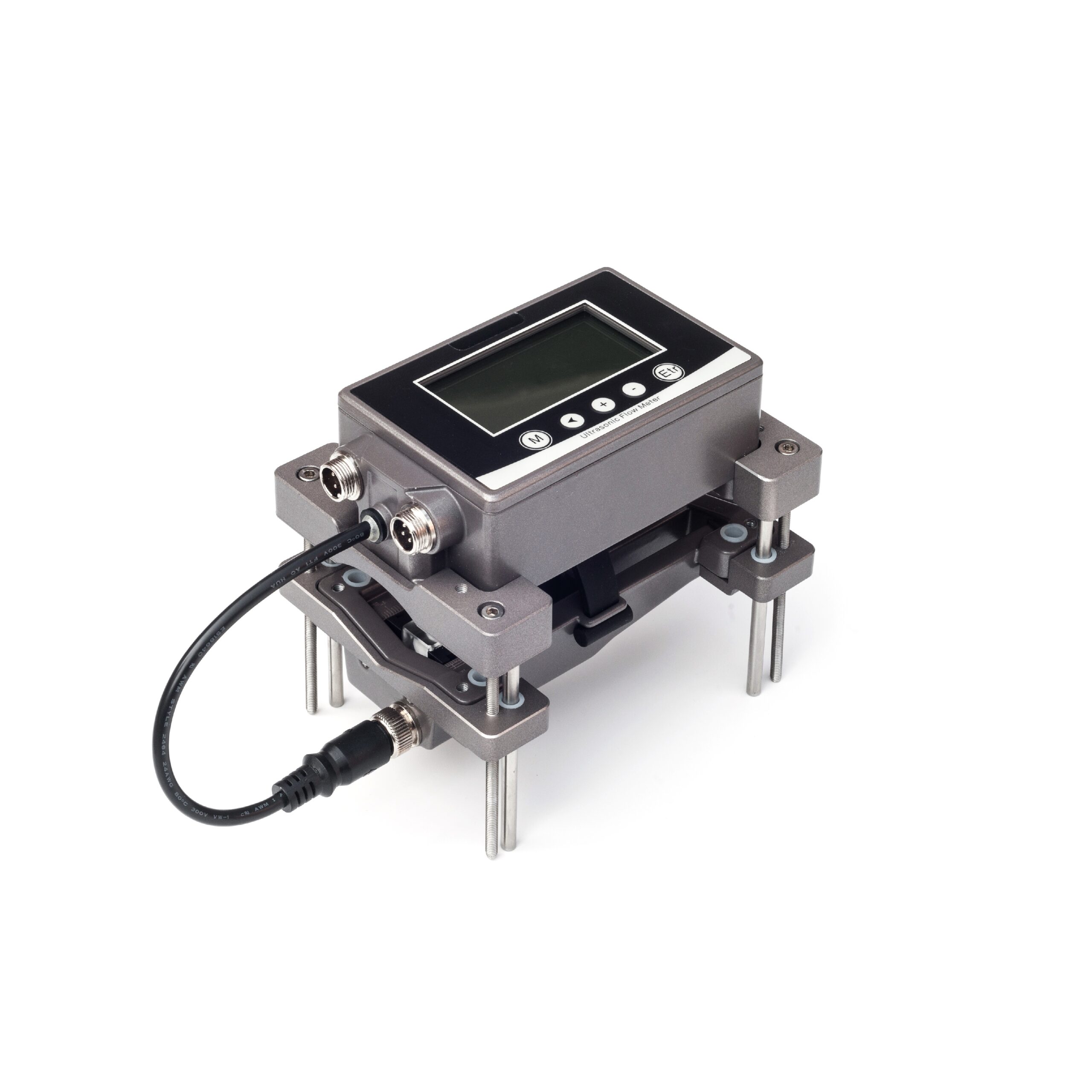

Clamp-on Ultrasonic BTU Meter System

Let me share my experience with these advanced measurement systems and their applications.

What is a Clamp-On Ultrasonic Flow Meter?

Many engineers struggle with choosing between traditional inline meters and non-invasive measurement solutions.

A clamp-on ultrasonic flow meter is a non-intrusive device that measures fluid flow from outside the pipe using ultrasonic signals, requiring no pipe modifications or process interruptions.

Clamp-on Ultrasonic Installation

From my field experience:

Operating Principles

Measurement Basics

Component Function Benefit Transducers Send/receive signals Non-invasive Electronics Signal processing Accurate results Mounting track Sensor positioning Easy installation Display unit Data presentation Clear readings Installation Considerations

- Pipe material

- Fluid properties

- Installation location

- Surface preparation

Key Features

Technical Advantages

- No pressure drop

- No system shutdown

- Bi-directional measurement

- Multiple pipe sizes

Application Benefits

- Portable or permanent

- Easy maintenance

- Cost-effective

- Versatile use

What is the Application of a BTU Meter?

Facility managers often need reliable ways to measure and allocate energy costs.

BTU meters are used to measure thermal energy consumption in heating and cooling systems, enabling accurate energy billing, system optimization, and efficiency monitoring.

BTU Meter Applications

Based on my implementation experience:

Common Applications

Building Systems

Application Purpose Benefit HVAC Energy monitoring Cost allocation District heating Consumption billing Fair charging Chiller plants System efficiency Optimization Process heating Energy management Cost control Industry Uses

- Energy auditing

- Performance verification

- Maintenance planning

- Efficiency improvement

Implementation Benefits

Operational Advantages

- Accurate billing

- System monitoring

- Fault detection

- Energy savings

Management Benefits

- Cost allocation

- Usage tracking

- Performance analysis

- Regulatory compliance

What is the Application of Ultrasonic Flowmeter?

Industries need reliable flow measurement solutions for various applications.

Ultrasonic flowmeters are widely used in water, chemical, oil and gas industries for accurate flow measurement of clean liquids, offering non-intrusive measurement capabilities.

Ultrasonic Flowmeter Applications

Industry Applications

Market Sectors

Industry Application Key Feature Water Distribution Large pipes Oil & Gas Custody transfer High accuracy Chemical Process control Non-contact Power Cooling systems Reliability Specific Uses

- Leak detection

- Process monitoring

- Quality control

- Revenue metering

Technical Considerations

Selection Criteria

- Fluid properties

- Pipe conditions

- Accuracy needs

- Installation requirements

Performance Factors

- Flow profile

- Reynolds number

- Signal strength

- Installation effects

How Does an Ultrasonic BTU Meter Work?

Understanding the working principle helps in proper installation and maintenance.

Ultrasonic BTU meters combine flow measurement using ultrasonic signals with temperature measurements from paired sensors to calculate thermal energy transfer.

BTU Meter Operation Principle

Based on my system design experience:

Operating Principle

Measurement Components

Element Function Output Flow sensor Volume measurement Flow rate Temperature sensors Delta-T measurement Temperature difference Calculator Energy computation BTU value Display/interface Data presentation Results Calculation Process

- Flow measurement

- Temperature sensing

- Energy calculation

- Data logging

System Integration

Installation Requirements

- Sensor placement

- Wiring connections

- Programming setup

- Communication interface

Operational Features

- Real-time monitoring

- Data recording

- Remote access

- System diagnostics

Conclusion

Clamp-on ultrasonic BTU meters provide a versatile, non-invasive solution for thermal energy measurement, combining accurate flow measurement with temperature sensing for comprehensive energy monitoring.