Incorrect flow measurements can lead to significant product loss, billing disputes, and compliance issues in industrial processes.

Flow meter accuracy standards are defined by organizations like ISO, with common requirements including accuracy classes from 0.1% to 2.0%, specified testing conditions, and calibration procedures.

Flow Meter Accuracy Standards Overview

Let me share my experience with flow meter accuracy standards to help you understand the requirements.

What is the ISO Standard for Flow Meter?

Many users struggle to understand which ISO standards apply to their flow meters.

The primary ISO standards for flow meters include ISO 4064/OIML R49 for water meters, ISO 17025 for calibration labs, and ISO 9001 for quality management systems.

ISO Standards for Flow Meters

Here’s what I’ve learned about ISO standards:

Key Standards Overview

Main Standards

Standard Application Focus Area ISO 4064 Water meters Accuracy classes ISO 17025 Calibration Lab requirements ISO 9001 Quality Management system ISO 5167 DP devices Installation Compliance Requirements

- Testing conditions

- Uncertainty calculations

- Documentation needs

- Verification periods

Implementation Guidelines

Standard Selection

- Application type

- Industry requirements

- Regulatory needs

- Customer specifications

Documentation Requirements

- Test procedures

- Calibration records

- Maintenance logs

- Verification reports

Understanding standards ensures compliance.

Which Flowmeter Has the Highest Accuracy?

Selecting the right flowmeter for high accuracy applications is crucial.

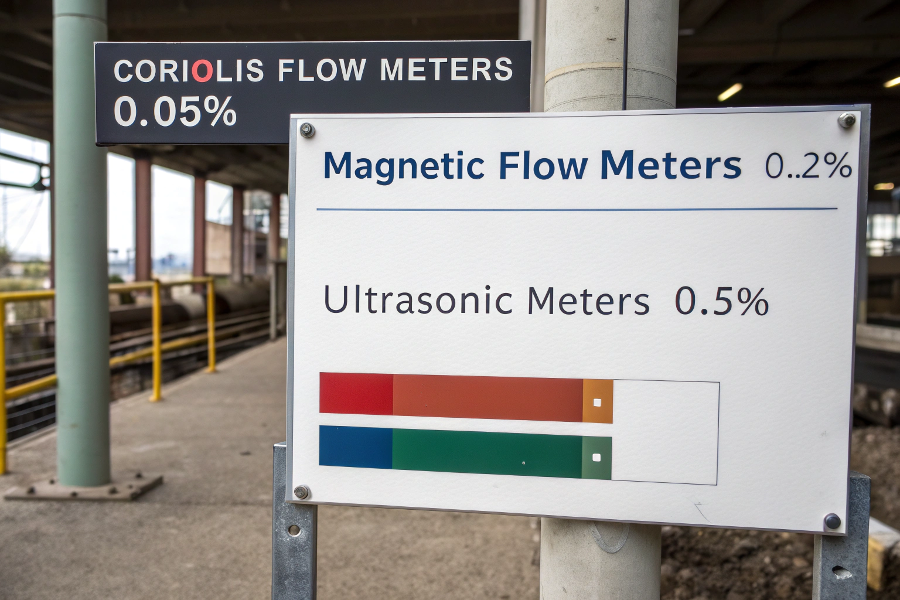

Coriolis flow meters typically achieve the highest accuracy of ±0.05% of rate, followed by magnetic flow meters at ±0.2% and ultrasonic meters at ±0.5%.

Flow Meter Accuracy Comparison

From my implementation experience:

Accuracy Comparison

Technology Rankings

Type Typical Accuracy Best Conditions Coriolis ±0.05% Clean liquids Magnetic ±0.2% Conductive fluids Ultrasonic ±0.5% Clean pipes Vortex ±0.7% Steady flow Application Factors

- Fluid properties

- Flow conditions

- Installation effects

- Environmental impact

Selection Criteria

Application Requirements

- Process conditions

- Accuracy needs

- Budget constraints

- Maintenance capability

Installation Considerations

- Straight run requirements

- Mounting position

- Environmental protection

- Access for maintenance

Proper selection ensures optimal accuracy.

What is the Tolerance of a Flow Meter?

Understanding tolerance helps set realistic expectations.

Flow meter tolerance typically ranges from ±0.05% to ±2.0% of reading, depending on the technology, application conditions, and calibration quality.

Flow Meter Tolerance Ranges

Based on my field experience:

Tolerance Factors

Technology Limits

Technology Base Tolerance Influencing Factors Coriolis ±0.05-0.1% Gas entrainment Magnetic ±0.2-0.5% Conductivity Ultrasonic ±0.5-1.0% Profile effects Thermal ±1.0-2.0% Flow range External Influences

- Installation effects

- Process variations

- Environmental conditions

- Maintenance quality

Performance Optimization

Best Practices

- Proper sizing

- Correct installation

- Regular calibration

- Routine maintenance

Monitoring Methods

- Performance tracking

- Error analysis

- Trend monitoring

- Documentation

Understanding tolerance aids application.

What is the Standard for Calibration of Flowmeter?

Proper calibration is essential for maintaining accuracy.

Flow meter calibration standards include ISO 17025 for laboratory procedures, traceability to national standards, and specific accuracy class requirements.

Flow Meter Calibration Standards

Here’s my calibration experience:

Calibration Requirements

Standard Elements

Element Requirement Purpose Traceability National standards Reference Uncertainty Documented calculation Accuracy Procedures Written methods Consistency Records Complete documentation Evidence Quality Assurance

- Equipment verification

- Personnel qualification

- Environmental control

- Data management

Implementation Steps

Calibration Process

- Pre-test checks

- Standard procedures

- Data collection

- Uncertainty analysis

Documentation Needs

- Calibration certificates

- Test conditions

- Results analysis

- Recommendations

Proper calibration maintains accuracy.

Conclusion

Understanding and following flow meter accuracy standards, selecting appropriate technology, managing tolerances, and maintaining proper calibration ensures reliable flow measurement in your applications.