Incorrect straight run installations can severely compromise flow measurement accuracy, leading to costly measurement errors.

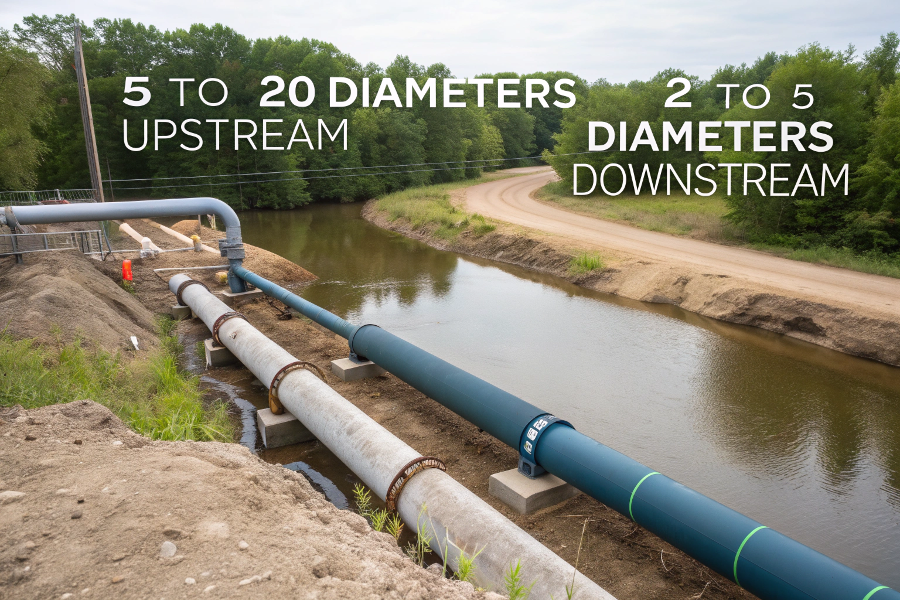

Flow meters typically require straight pipe runs of 5-20 diameters upstream and 2-5 diameters downstream, with specific requirements varying by meter type and installation conditions.

Flow Meter Straight Run Overview

Let me share what I’ve learned from years of flow meter installations and troubleshooting.

What is the Straight Run Requirement for Flow Meters?

Poor straight run installations can create flow profile distortions that lead to measurement errors up to 20%.

Different flow meters have varying straight run requirements based on their measuring principles, with upstream requirements ranging from 5-20 diameters and downstream from 2-10 diameters.

Flow Meter Installation Requirements

From my installation experience:

General Requirements

Meter Type Comparison

Meter Type Upstream (D) Downstream (D) Magnetic 5 3 Ultrasonic 10 5 Vortex 15 5 Turbine 20 5 Influencing Factors

- Pipe configuration

- Flow disturbances

- Installation location

- Process conditions

Installation Considerations

Common Disturbances

- Elbows

- Valves

- Pumps

- Reducers/expanders

Mitigation Methods

- Flow straighteners

- Installation alternatives

- Meter selection

- Location optimization

Understanding requirements ensures accurate measurement.

What is the Straight Run Requirement for Turbine Flow Meter?

Turbine meters are particularly sensitive to flow profile distortions, making proper straight run critical.

Turbine flow meters require 20 pipe diameters upstream and 5 pipe diameters downstream for optimal performance, with additional length needed after flow disturbances.

Turbine Meter Installation Requirements

Based on my turbine meter experience:

Turbine-Specific Requirements

Installation Factors

Disturbance Upstream (D) Downstream (D) Single Elbow 20 5 Double Elbow 30 5 Control Valve 40 5 Pump 50 5 Critical Considerations

- Bearing wear

- Flow profile

- Velocity range

- Support requirements

Performance Optimization

Installation Best Practices

- Proper orientation

- Support methods

- Alignment needs

- Calibration access

Maintenance Considerations

- Regular inspection

- Bearing checks

- Calibration schedule

- Performance monitoring

Proper installation ensures long-term reliability.

What Are the Requirements for a Magnetic Flow Meter Straight Run?

Magnetic flow meters offer more flexible installation options but still need proper straight runs.

Magnetic flow meters typically require 5 pipe diameters upstream and 3 pipe diameters downstream, with some variations based on specific installation conditions.

Magnetic Flow Meter Installation Guide

From my magnetic meter installations:

Magnetic Meter Requirements

Installation Guidelines

Condition Upstream (D) Downstream (D) Ideal 5 3 After Pump 10 3 After Valve 8 3 After Reducer 5 3 Installation Factors

- Grounding requirements

- Empty pipe detection

- Electrode position

- Liner considerations

Application Considerations

Process Conditions

- Conductivity requirements

- Flow profile

- Air entrainment

- Coating prevention

Mounting Options

- Vertical installation

- Horizontal placement

- Support methods

- Access requirements

Proper magnetic meter installation ensures accuracy.

What is the Straight Length Requirement for Ultrasonic Flow Meter?

Ultrasonic flow meters need specific straight run conditions for accurate signal transmission.

Ultrasonic flow meters generally require 10 pipe diameters upstream and 5 pipe diameters downstream, with requirements varying based on the number of paths and installation type.

Ultrasonic Flow Meter Installation Details

Based on my ultrasonic meter experience:

Ultrasonic-Specific Requirements

Path Configuration Impact

Path Type Upstream (D) Downstream (D) Single Path 15 5 Dual Path 10 5 Multi-Path 8 5 Clamp-On 20 5 Installation Factors

- Signal strength

- Mounting location

- Pipe condition

- Environmental effects

Performance Optimization

Installation Considerations

- Transducer placement

- Signal quality

- Temperature effects

- Noise reduction

Maintenance Needs

- Regular verification

- Signal checks

- Cleaning requirements

- Calibration schedule

Proper ultrasonic installation ensures reliable measurement.

Conclusion

Understanding and implementing proper straight run requirements for different flow meter types is essential for achieving accurate flow measurement and optimal system performance.