Many plant operators struggle with unreliable level measurements, leading to process disruptions and maintenance headaches.

Troubleshooting ultrasonic level sensors involves systematic checking of power supply, signal quality, sensor alignment, and environmental conditions. A structured approach helps identify and resolve issues quickly.

Ultrasonic Level Sensor Troubleshooting Steps

Let me share practical troubleshooting methods I’ve developed through years of field experience.

How Do I Check Whether My Ultrasonic Sensor Is Working or Not?

Quick verification can save hours of troubleshooting time.

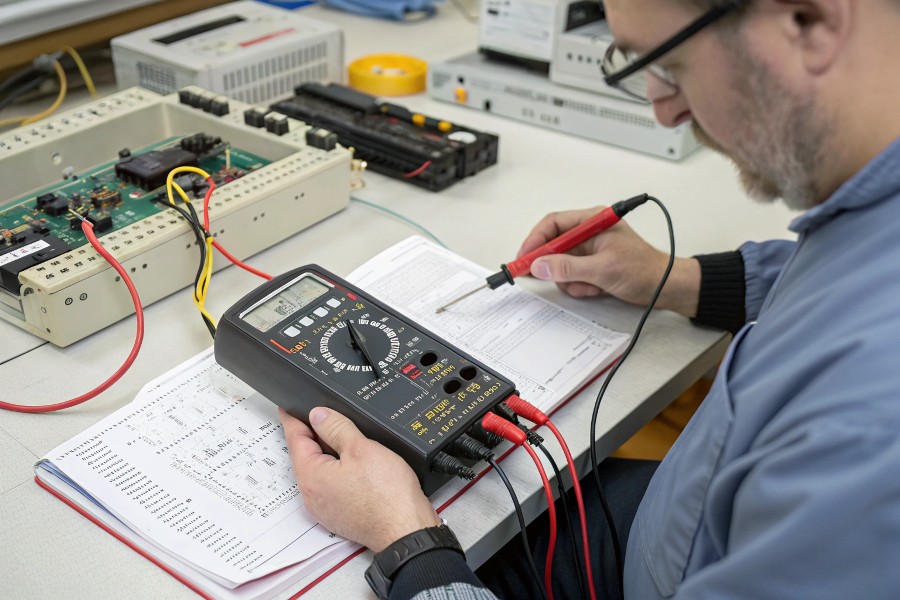

Start by checking the power supply voltage, output signal, and LED status indicators. Most sensors provide diagnostic information through these basic indicators.

Ultrasonic Sensor Diagnostic Points

Here’s my proven verification process:

Basic Checks

Power and Signal

Check Point Normal Range Action Supply voltage 24V ±10% Measure with multimeter Output current 4-20mA Check loop current LED status Green/steady Observe indicators Display reading Expected range Compare with actual Physical Inspection

- Sensor alignment

- Cable connections

- Mounting stability

- Environmental conditions

Advanced Verification

Signal Quality

- Echo strength

- Signal stability

- Noise levels

- Temperature readings

Communication Test

- HART communication

- Parameter access

- Configuration check

- Error messages

These steps provide a comprehensive working status check.

How to Troubleshoot Level Sensor?

A systematic approach ensures efficient problem resolution.

Follow a structured troubleshooting process: verify power, check signal quality, inspect physical installation, and evaluate environmental conditions. Document each step for future reference.

Level Sensor Troubleshooting Process

From my maintenance experience:

Systematic Approach

Initial Assessment

- Gather operational data

- Review recent changes

- Check maintenance history

- Document symptoms

Testing Sequence

Step Action Expected Result Power check Measure voltage 24V ±10% Signal test Monitor output Stable reading Physical inspection Visual check No damage Configuration verify Parameter review Correct settings

Problem Resolution

Common Solutions

- Power cycle

- Recalibration

- Cleaning sensor

- Parameter reset

Advanced Solutions

- Signal analysis

- Echo mapping

- Environmental adjustment

- Hardware replacement

These methods ensure efficient problem solving.

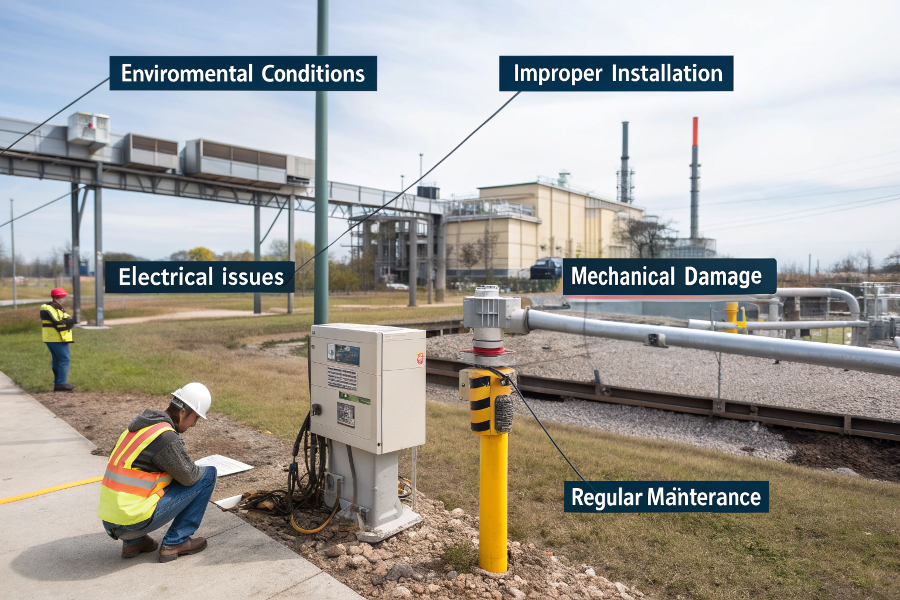

Why Do Ultrasonic Sensors Fail?

Understanding failure modes helps prevent future issues.

Ultrasonic sensors typically fail due to environmental conditions, improper installation, electrical issues, or mechanical damage. Regular maintenance can prevent many common failures.

Ultrasonic Sensor Failure Modes

Based on my troubleshooting experience:

Common Failure Modes

Environmental Factors

- Temperature extremes

- Excessive vapor

- Chemical exposure

- Mechanical vibration

Installation Issues

Problem Impact Prevention Misalignment False readings Proper mounting Poor grounding Signal noise Correct wiring Cable damage Signal loss Protection Mounting stress Physical damage Proper support

Prevention Strategies

Regular Maintenance

- Cleaning schedule

- Connection checks

- Calibration verification

- Environmental monitoring

Design Considerations

- Proper sensor selection

- Adequate protection

- Correct installation

- Environmental control

These strategies minimize failure risks.

What Are the Sources of Error in an Ultrasonic Sensor?

Identifying error sources enables better measurement accuracy.

Error sources include temperature variations, vapor interference, turbulent surfaces, and improper installation. Understanding these helps in implementing effective solutions.

Ultrasonic Sensor Error Sources

From my optimization experience:

Error Categories

Environmental Factors

Source Impact Solution Temperature Reading drift Compensation Vapor Signal loss Ventilation Turbulence False echoes Stilling well Pressure Speed changes Correction Technical Factors

- Signal processing

- Echo detection

- Resolution limits

- Response time

Error Management

Prevention Methods

- Regular calibration

- Environmental control

- Proper installation

- Signal monitoring

Correction Techniques

- Temperature compensation

- Signal filtering

- Echo validation

- Parameter adjustment

Understanding these factors improves measurement reliability.

Conclusion

Successful troubleshooting of ultrasonic level sensors requires systematic approach, understanding of common failure modes, and proper maintenance practices. Regular monitoring and preventive maintenance ensure reliable operation.