Poorly maintained flow meters can cost thousands in inaccurate measurements and unexpected breakdowns.

Flow meter maintenance involves regular inspection, cleaning, calibration, and parts replacement to ensure accuracy and longevity, typically requiring scheduled checks every 6-12 months.

Flow Meter Maintenance Overview

Through my years of experience maintaining various flow measurement systems, I’ve developed comprehensive maintenance strategies.

What is the Maintenance of Flow Meter?

Neglecting flow meter maintenance can lead to costly measurement errors and system failures.

Flow meter maintenance includes visual inspections, cleaning, calibration verification, and component checks, following a structured schedule based on the meter type and application.

Flow Meter Maintenance Steps

From my maintenance experience:

Maintenance Procedures

Regular Tasks

Task Frequency Purpose Visual Inspection Monthly Detect issues early Cleaning Quarterly Prevent buildup Calibration Check Annually Ensure accuracy Parts Inspection Semi-annually Prevent failures Critical Checks

- Signal output verification

- Zero point validation

- Leak detection

- Electronics testing

Documentation Requirements

Maintenance Records

- Service dates

- Work performed

- Parts replaced

- Test results

Performance Tracking

- Accuracy trends

- Error patterns

- Repair history

- Calibration data

Proper maintenance ensures reliability.

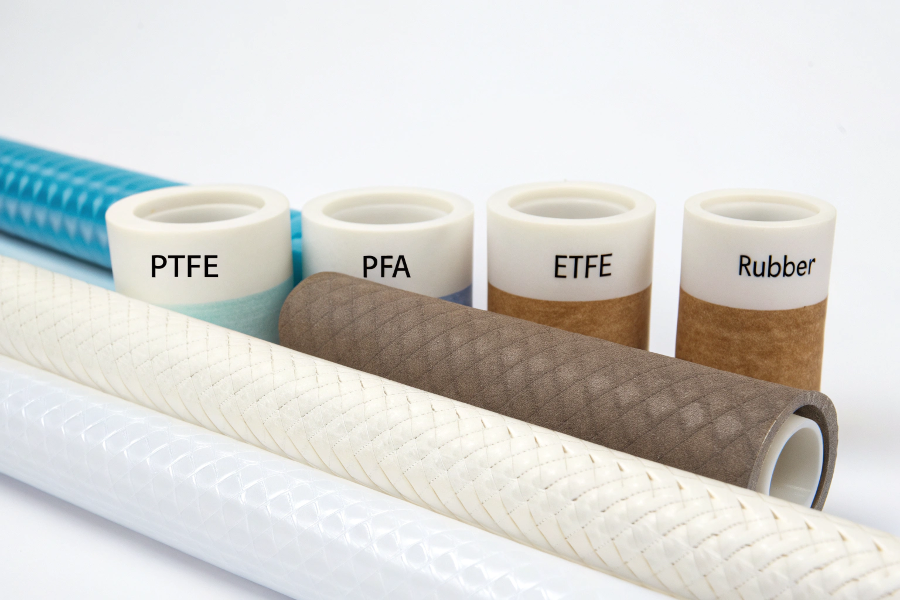

What Material is Used for Flow Meter Liner?

Selecting the wrong liner material can result in premature wear and chemical compatibility issues.

Flow meter liners commonly use PTFE, PFA, ETFE, rubber, or ceramic materials, chosen based on the fluid properties, temperature, and chemical compatibility requirements.

Flow Meter Liner Materials

Based on my installation experience:

Liner Material Selection

Common Materials

Material Temperature Range Best Application PTFE -40°C to 180°C Corrosive fluids Hard Rubber -20°C to 80°C Abrasive slurries PFA -40°C to 200°C High purity Ceramic Up to 800°C Extreme conditions Selection Factors

- Chemical resistance

- Temperature limits

- Wear resistance

- Cost considerations

Application Guidelines

Industry Requirements

- Chemical processing

- Food and beverage

- Water treatment

- Mining operations

Installation Considerations

- Mounting position

- Environmental conditions

- Maintenance access

- Safety requirements

Proper material selection ensures longevity.

How Often Do Flow Meters Need to be Calibrated?

Incorrect calibration intervals can lead to measurement drift and compliance issues.

Flow meters typically require calibration every 6-12 months, though frequency varies based on application, regulatory requirements, and manufacturer specifications.

Flow Meter Calibration Process

From my calibration experience:

Calibration Schedule

Industry Standards

Industry Frequency Requirements Custody Transfer 3-6 months High accuracy Process Control 6-12 months Standard accuracy Utilities Annual Compliance focus Non-critical 12-24 months Basic accuracy Influencing Factors

- Process conditions

- Fluid properties

- Accuracy requirements

- Regulatory demands

Calibration Process

Verification Steps

- Zero point check

- Span verification

- Linearity test

- Response time check

Documentation

- Calibration certificates

- Test conditions

- As-found readings

- As-left readings

Regular calibration ensures accuracy.

How Often Should You Clean a Peak Flow Meter?

Dirty flow meters can provide false readings and compromise system efficiency.

Peak flow meters should be cleaned after each use for hygienic applications, while industrial meters typically require cleaning every 3-6 months depending on fluid conditions.

Flow Meter Cleaning Procedures

Based on my maintenance protocols:

Cleaning Requirements

Cleaning Schedule

Application Frequency Method Sanitary After each use CIP/SIP Industrial Quarterly Manual/CIP Utility Semi-annual Basic flush Laboratory Monthly Detailed clean Cleaning Methods

- Chemical cleaning

- Mechanical cleaning

- Ultrasonic cleaning

- Steam sterilization

Maintenance Procedures

Cleaning Steps

- Disassembly (if required)

- Cleaning application

- Inspection

- Reassembly

Quality Checks

- Visual inspection

- Performance testing

- Documentation

- Validation

Regular cleaning ensures performance.

Conclusion

Proper flow meter maintenance, including regular cleaning, calibration, and appropriate material selection, is essential for accurate measurements and extended equipment life.