Need to measure steam or clean liquid flows? Vortex flow meters offer unique benefits but require careful application considerations. Understanding their pros and cons helps select the right technology.

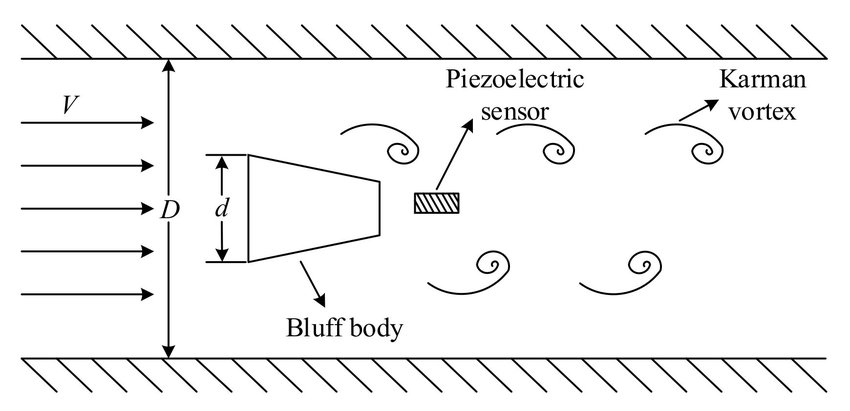

Vortex flow meters measure fluid velocity by detecting vortices shed from a bluff body, offering non-intrusive measurement for liquids, gases and steam with no moving parts. Their reliability makes them popular in chemical, oil & gas, and HVAC applications when properly specified.

Vortex Shedding Principle

While electromagnetic and ultrasonic flowmeters dominate discussions, vortex technology occupies a vital niche. Let’s examine when these devices excel and where alternatives perform better.

What Are the Advantages of a Vortex Flow Meter?

Why choose vortex over other technologies? Three compelling reasons make these meters ideal for certain applications.

1. Superior reliability in clean fluid applications

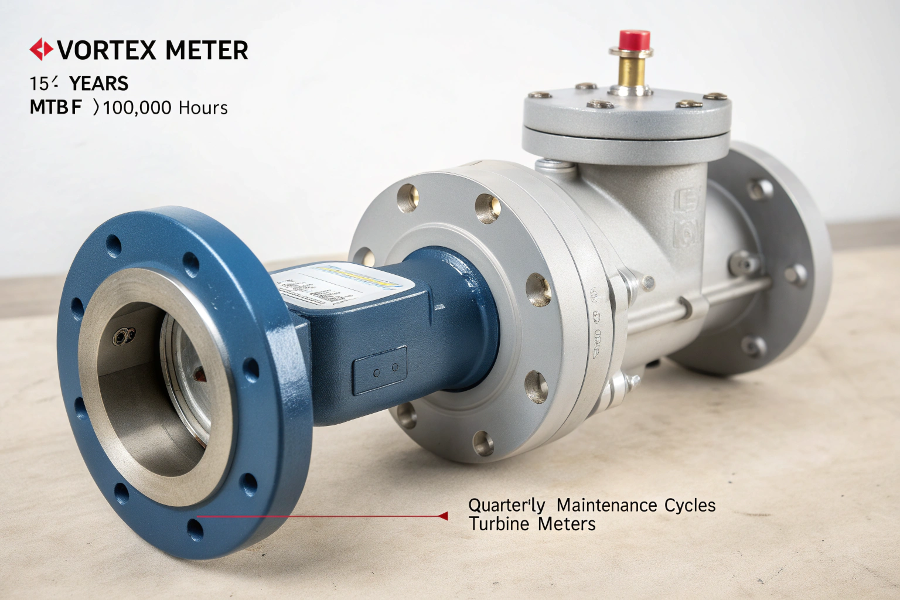

With no bearings or moving parts subject to wear, vortex meters outlast mechanical alternatives:

- Typical lifespan: 15+ years

- MTBF: >100,000 hours

- Maintenance cycles: Annual verification vs quarterly for turbine meters

Mechanical Comparison

2. Excellent steam measurement capabilities

No other technology combines steam measurement advantages so effectively:

- Handles saturated and superheated steam

- Withstands temperatures to 450°C

- No pressure drop issues like orifice plates

- Lower cost than Coriolis alternatives

3. Cost-effective performance balance

Vortex meters hit a sweet spot between:

- Price: 1/3 cost of comparable Coriolis

- Accuracy: ±0.75% for liquid, ±1% for gas

- Durability: 5x lifespan of turbine meters

| Feature | Vortex | Turbine | Coriolis |

|---|---|---|---|

| Initial Cost | $$ | $ | $$$$ |

| Lifetime Cost | $ | $$$ | $$ |

| Steam Suitability | ★★★★★ | ★★☆ | ★★★★ |

What Are the Disadvantages of Vortex Flow Meters?

Despite strengths, vortex technology has inherent constraints requiring careful evaluation.

1. Minimum flow velocity requirements

Below threshold velocities, vortex shedding stops:

- Typical minimum: 0.3 m/s liquids, 3 m/s gases

- Varies by pipe size and manufacturer

- Creates "no flow" dead zone in turndown

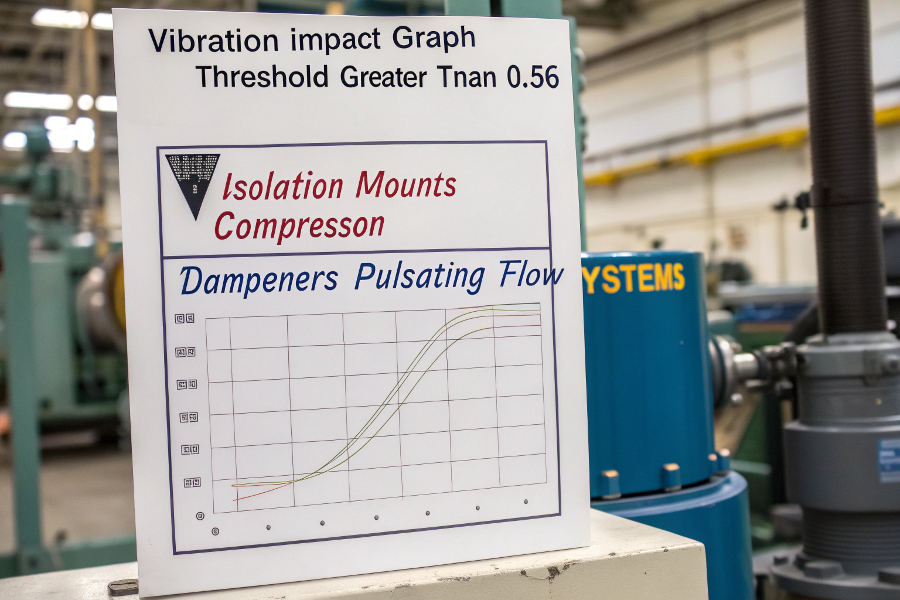

2. Sensitivity to vibration and pulsation

Mechanical vibrations cause false readings:

- Threshold: >0.5g vibration

- Requires isolation mounts in pumps/compressor areas

- Pulsating flows need dampeners

Vibration Error Analysis

3. Limited dirty fluid capability

Performance degrades with:

- Solids >5% concentration

- Viscosity >30 cP

- Wax or gum-forming fluids

What Are the Limitations of Vortex Flowmeter?

Understanding operation boundaries prevents misapplication.

Pipe Size Constraints

Optimal performance occurs in:

- 1/2" to 12" pipes (DN15-DN300)

- Larger sizes possible but expensive

- Small sizes have higher minimum flows

Fluid Property Requirements

Must maintain:

- Reynolds number >10,000

- Relatively stable density

- Non-pulsating flow

Installation Demands

Requires proper:

- Upstream straight runs (15-30D)

- Downstream straight runs (5D)

- Flow conditioning elements

What Is the Problem With the Vortex Flow Meter?

Field issues commonly stem from four root causes:

1. Low flow conditions

Symptoms:

- Intermittent signal dropout

- Accuracy degradation

Solutions:

- Verify actual vs required minimum flow

- Consider smaller pipe size

- Switch to thermal meter if needed

2. Vibration interference

Symptoms:

- Random flow spikes

- Non-zero readings at rest

Solutions:

- Add vibration isolators

- Relocate meter if possible

- Enable vibration filtering

3. Improper orientation

Symptoms:

- Liquid/gas measurement errors

- Drainage/ventilation issues

Solutions:

- Liquid: Horizontal only

- Gas: Vertical upwards preferred

- Steam: Follow manufacturer guidance

4. Installation effects

Symptoms:

- Consistent measurement offset

- Poor repeatability

Solutions:

- Verify straight run requirements

- Install flow conditioner

- Check for partially closed valves

How to Select the Right Vortex Flow Meter?

Match these five application factors to specifications:

1. Process Media Characteristics

- Clean liquids/gases: Excellent fit

- Steam: Ideal application

- Slurries/high viscosity: Avoid

2. Flow Profile Conditions

Evaluate:

- Reynolds number range

- Flow velocity range

- Pulsation frequency

3. Environmental Factors

Account for:

- Ambient vibration levels

- Temperature extremes

- Hazardous area requirements

4. Performance Needs

Specify:

- Required accuracy (±0.5% vs ±1%)

- Turndown requirements (10:1 typical)

- Output/communication needs

5. Maintenance Considerations

Plan for:

- Access requirements

- Spare part availability

- Calibration frequency

Vortex Meter Selection Process

For marginal applications, consider:

- Hybrid vortex+ultrasonic designs

- Dual-technology verification

- Manufacturer application review

Conclusion

Vortex flow meters deliver reliable, cost-effective measurement for steam and clean fluids above minimum velocities. Their no-moving-part design excels where turbine and positive displacement meters fail, while avoiding Coriolis price premiums. Successful implementation requires careful attention to vibration control, low-flow avoidance, and proper installation practices – when these conditions are met, vortex meters provide outstanding long-term service with minimal maintenance. For challenging applications beyond their ideal operating envelope, combining vortex technology with complementary measurement principles often yields optimal results.