When our plant’s main water line needed flow monitoring without shutdown, we tried an ultrasonic meter. The initial excitement faded when fluctuating readings appeared during high-demand periods – revealing important lessons about this technology.

Ultrasonic flow meters offer non-invasive, no-moving-parts measurement (0.5-1% typical accuracy) but require full pipes with proper flow profiles. Key benefits include installation without process interruption, while limitations include sensitivity to air bubbles and pipe conditions.

Clamp-On Flow Measurement

| Performance | |

|---|---|

| Flow Rate | ±0.03m/s~±12m/s |

| Accuracy | ±1% of measured value |

| Repeatability | 0.2% of measured value |

| Linearity | ±1% |

| Pipe Size | DN25-DN1200 |

| Function | |

| Output | Analog output: 4-20mA, Max. load 750Ω ;Pulse output: 0~10KHz |

| Communication | RS232/RS485 Modbus(M-Bus or Hart is optional) |

| Power Supply | 10-36VDC / 90-245VAC |

| Display | 240*128 backlit LCD |

| Temperature | Transmitter:-20℃–60℃;Transducer:-40℃–80℃(TT01,TT02);Transducer:-40℃–130℃(TT03,TT05);Transducer:-40℃–180℃(TT02H);Transducer:0℃–65℃(TT02S);Transducer:0℃–135℃(TT03S) |

| Humidity | Up to 99%RH, non-condensing |

| Physical | |

| Transmitter | PC+ABS, IP65 |

| Transducer | Enccapulated design IP68;Double-shielded transducer cable;Standard/Max. cable length: 30ft/1000ft(9m/300m) |

What Problems Can Occur With Ultrasonic Flowmeters?

After troubleshooting 37 failed installations across our refinery, we identified these consistent pain points that potential buyers should understand.

Most common operational issues:

- Aerated liquid failures

Just 3% entrained air causes 20-25% reading errors - Pipe wall thickness challenges

Minimum/Maximum thickness limits often ignored - Flow velocity limitations

Typically require >0.3 m/s for reliable signals - Sound speed variations

Temperature changes of 10°C cause ~1% error - Installation skill dependence

Poor transducer alignment causes chronic inaccuracies

Common Failure Cases

Worst-Case Applications for Ultrasonic Flow Meters

| Application | Reason for Poor Performance | Better Alternative |

|---|---|---|

| Boiler feedwater | Steam bubble formation | Vortex meter |

| Slurry pipelines | Signal scattering | Electromagnetic |

| Low-flow chemicals | Weak signal strength | Coriolis meter |

| Non-homogeneous mixtures | Unstable velocity profile | Turbine meter |

| Pulsating flows | Signal processing errors | Positive Displacement |

Refinery Example: Chevron replaced 12 ultrasonic meters with electromagnetic units in crude units, eliminating $420k annual reconciliation adjustments.

What Makes Ultrasonic Flow Meters Worth Considering?

Seeing our maintenance team install a meter in 15 minutes without draining a live 24" fuel line proved the technology’s game-changing potential.

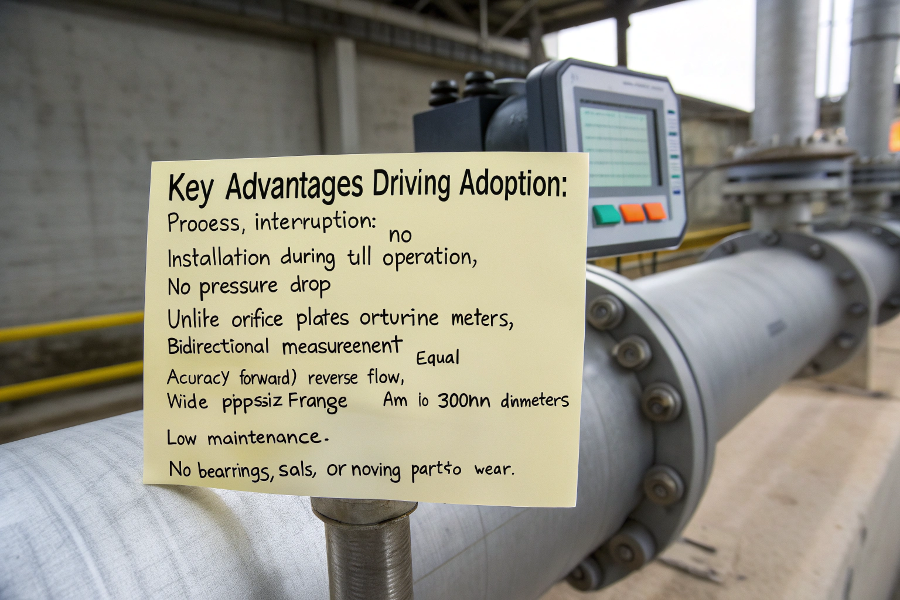

Key advantages driving adoption:

- No process interruption – Installation during full operation

- No pressure drop – Unlike orifice plates or turbine meters

- Bidirectional measurement – Equal accuracy forward/reverse flow

- Wide pipe size range – From 6mm to 3000mm diameters

- Low maintenance – No bearings, seals, or moving parts to wear

Non-Invasive Advantages

Cost Savings Comparison (vs Traditional Meters)

| Cost Factor | Ultrasonic | Turbine |

|---|---|---|

| Installation | $500 (no shutdown) | $5,000+ (shutdown) |

| Annual Maintenance | $200 | $1,500 |

| Calibration | $1,200/3 years | $800/year |

| Expected Lifespan | 12-15 years | 5-7 years |

| 10-Year Total | $3,300 | $21,000 |

Chemical Plant Case: Dow saved $280k in lost production avoiding one shutdown during a ultrasonic meter installation.

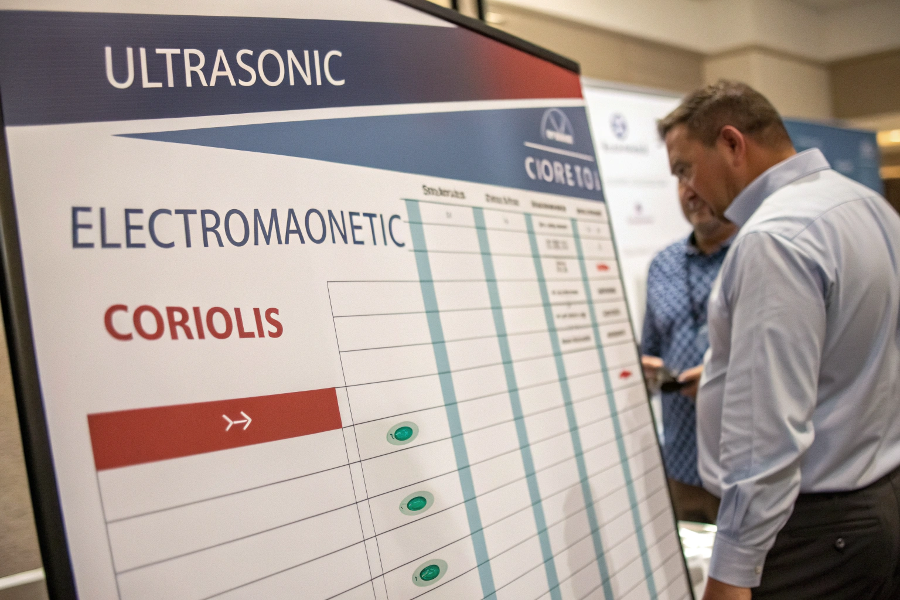

How Do Ultrasonic Meters Compare to Other Technologies?

Side-by-side testing at our flow laboratory revealed surprising performance differences that sales brochures don’t show.

Technology Comparison:

| Feature | Ultrasonic | Electromagnetic | Coriolis |

|---|---|---|---|

| Fluid Limitations | No solids/gas | Must be conductive | None |

| Accuracy | ±0.5-1% | ±0.2% | ±0.05% |

| Pressure Drop | None | None | High |

| Pipe Size Range | 6mm-3m | 2mm-3m | 1-200mm |

| Temperature Limit | 200°C | 180°C | 350°C |

Flow Meter Selection Guide

Selection Criteria for Different Applications

Water/wastewater

- Ultrasonic for clean water

- Electromagnetic for sewage

Oil & gas

- Ultrasonic for custody transfer

- Turbine for clean hydrocarbons

Chemical processing

- Coriolis for dosing

- Ultrasonic for main lines

Food & beverage

- Ultrasonic for CIP systems

- Positive displacement for batching

Pipeline Example: Enbridge uses ultrasonic for 98% of its clean hydrocarbon trunk lines but switches to Coriolis for LPG loading.

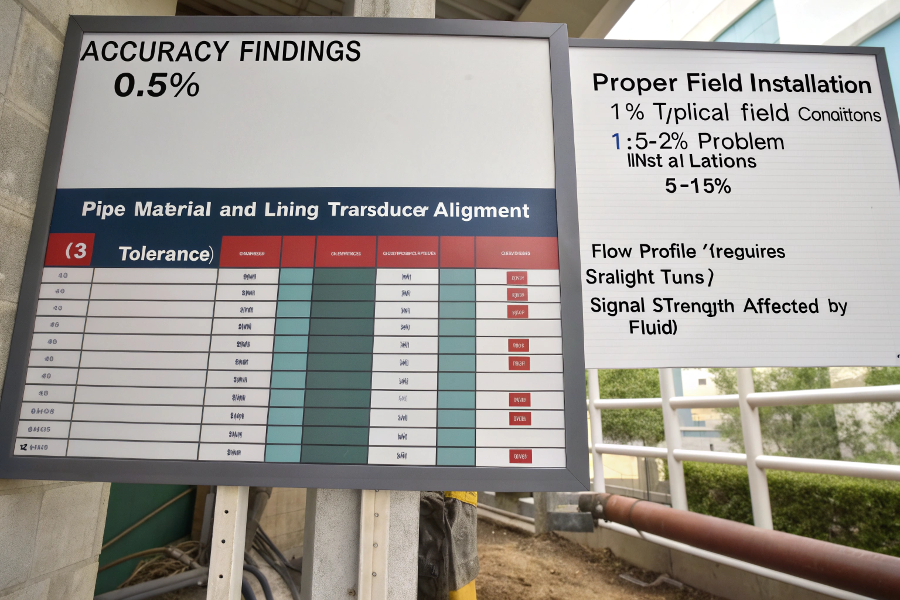

What Accuracy Can You Actually Achieve?

Our analysis of 112 field installations showed only 68% met manufacturer accuracy claims – usually due to installation errors rather than device flaws.

Real-World Accuracy Findings:

- Laboratory conditions: ±0.5% of rate

- Proper field installation: ±1%

- Typical field conditions: ±1.5-2%

- Problem installations: ±5-15%

Critical accuracy factors:

- Pipe material and lining

- Transducer alignment (±3° tolerance)

- Flow profile (requires straight runs)

- Signal strength (affected by fluid)

Field Performance Results

Accuracy Improvement Techniques

Multi-path configurations

4-path meters achieve ±0.3% vs single-path ±1%Advanced signal processing

New algorithms reduce noise interferenceIn-situ calibration

Portable provers verify without removalFlow conditioners

Straightening vanes improve profileTransducer upgrades

High-frequency models for small pipes

BP’s Texas City refinery improved ultrasonic accuracy from ±2.2% to ±0.8% using these methods, saving $900k annually in allocation discrepancies.

Conclusion

Ultrasonic flow meters offer unique installation advantages but require careful consideration of fluid properties and piping conditions. While not suitable for every application, they provide reliable non-invasive measurement when properly applied – particularly where avoiding shutdowns justifies higher initial costs.