Process engineers often underestimate piping requirements, resulting in measurement errors up to 5%. Correct straight-run distances prevent these costly mistakes.

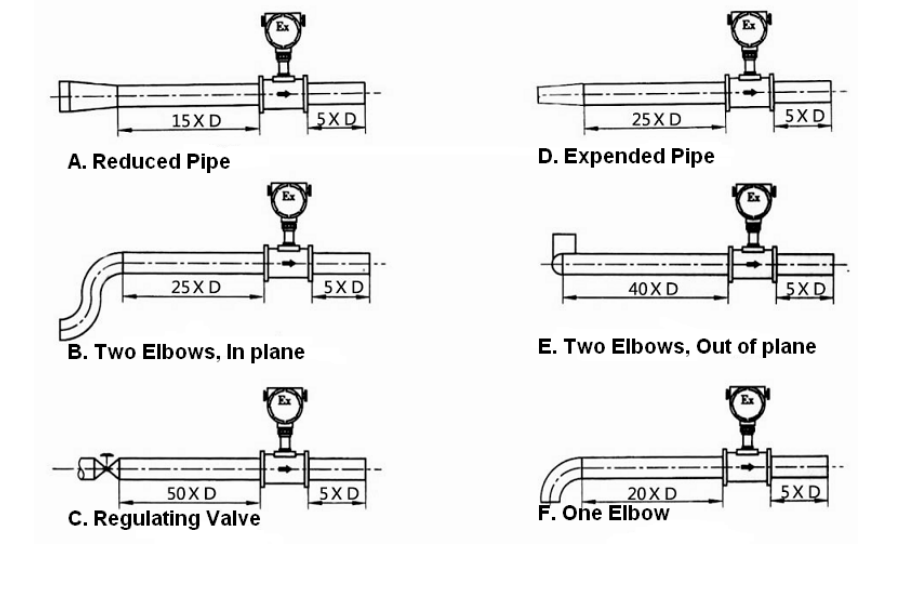

Vortex flow meters typically require 15 pipe diameters (15D) upstream and 5D downstream of straight, unobstructed piping. These distances ensure fully developed flow profiles, with reduced requirements possible using flow conditioners (10D upstream/3D downstream). Installation near pumps or valves demands increased distances up to 50D upstream.

Straight-Run Requirements

Three fundamentals govern installation: fluid properties, piping configuration, and meter design.

What Are the Upstream and Downstream Requirements for Ultrasonic Flow Meter?

Three ultrasonic meter types with distinct needs:

Straight-Run Comparison Table

| Ultrasonic Type | Minimum Upstream | Minimum Downstream | Special Notes |

|---|---|---|---|

| Clamp-on | 10D | 5D | Very flow-profile dependent |

| Insertion | 15D | 5D | More tolerant than clamp-on |

| In-line | 10D | 3D | Contains flow conditioning |

Installation Best Practices

Transit Time Meters

- Avoid vertical downward gas flow

- Maintain full pipes for liquids

- Keep transducers clean

Doppler Meters

- Install in turbulent regions

- Ensure particle concentration

- More tolerant of disturbances

Hybrid Meters

- Follow manufacturer specs

- May accept 5D upstream

- Need calibration validation

Ultrasonic Meter Piping

Flow Condition Impact Table

| Condition | Additional Requirements |

|---|---|

| Swirling Flow | +10D upstream |

| Pulsating Flow | Dampener required |

| Two-Phase Flow | Not recommended |

| High Viscosity | +5D heating may be needed |

| Low Conductivity | Grounding rings suggested |

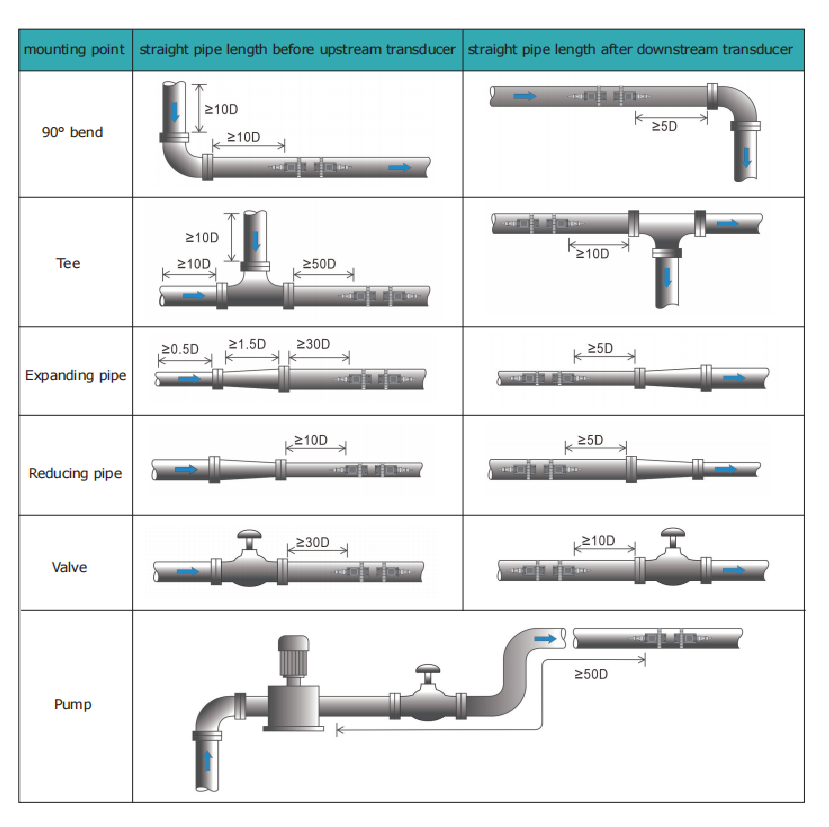

What Are Upstream and Downstream Requirements?

Five fundamental concepts affecting all meters:

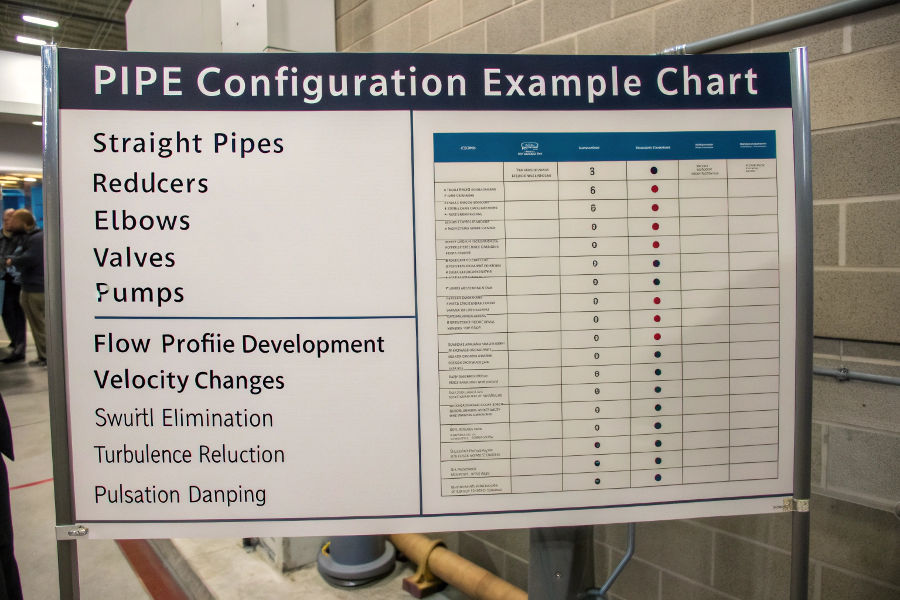

General Requirements Chart

| Pipe Feature | Typical Upstream | Typical Downstream | Reason |

|---|---|---|---|

| Straight Pipe | 10D-50D | 5D | Flow profile development |

| Reducer | 10D | 5D | Velocity changes |

| Elbow | 20D | 10D | Swirl elimination |

| Valve | 30D | 10D | Turbulence reduction |

| Pump | 50D | 15D | Pulsation damping |

Key Influencing Factors

Fluid Properties

- Gases need more distance

- Steam requires careful drainage

- Slurries have special rules

Measurement Importance

- Custody transfer: +50% distance

- Process control: Standard distance

- Monitoring: Can reduce slightly

Pipe Size

- Small pipes (<2"): +5D

- Large pipes (>12"): May reduce 20%

Pipe Configuration Examples

Exception Cases

- Compact Installation: Flow conditioners allow 50% reduction

- Non-Circular Pipes: Special calculations needed

- High Accuracy Needs: Double standard distances

- Retrofit Situations: May accept some compromise

- Multi-Meter Runs: Need individual conditioning

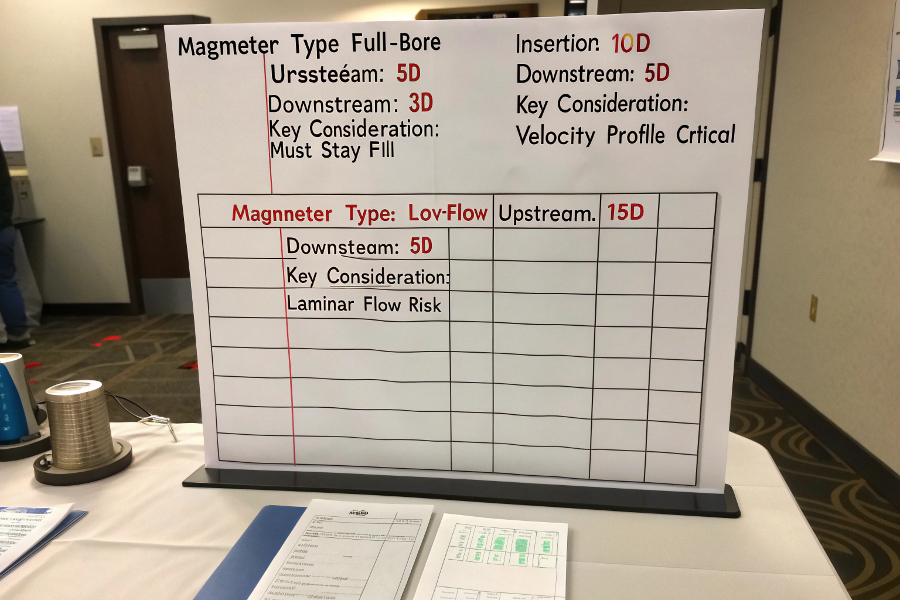

What Are the Upstream and Downstream Requirements for Magnetic Flow Meter?

Three magmeter categories with specific needs:

Installation Standards Table

| Magmeter Type | Upstream | Downstream | Key Consideration |

|---|---|---|---|

| Full-Bore | 5D | 3D | Must stay full |

| Insertion | 10D | 5D | Velocity profile critical |

| Low-Flow | 15D | 5D | Laminar flow risk |

Critical Installation Rules

Grounding Requirements

- Earth ground for all meters

- Grounding rings for non-conductive pipes

- Proper cable shielding

Orientation Guidelines

- Avoid top-of-pipe gas accumulation

- Preferred: Horizontal or vertical up

- Never install upside down

Electrode Maintenance

- Access for cleaning

- Check coating buildup

- Verify signal strength

Proper Grounding Setup

Conductivity Requirements

| Fluid Type | Minimum Conductivity | Typical Application |

|---|---|---|

| Water | 5 μS/cm | Most applications |

| Acids | 50 μS/cm | Chemical processing |

| Slurries | 500 μS/cm | Mining operations |

| Organic Liquids | 1000 μS/cm | Pharmaceuticals |

| Ultra-Pure Water | Not recommended | Semiconductor |

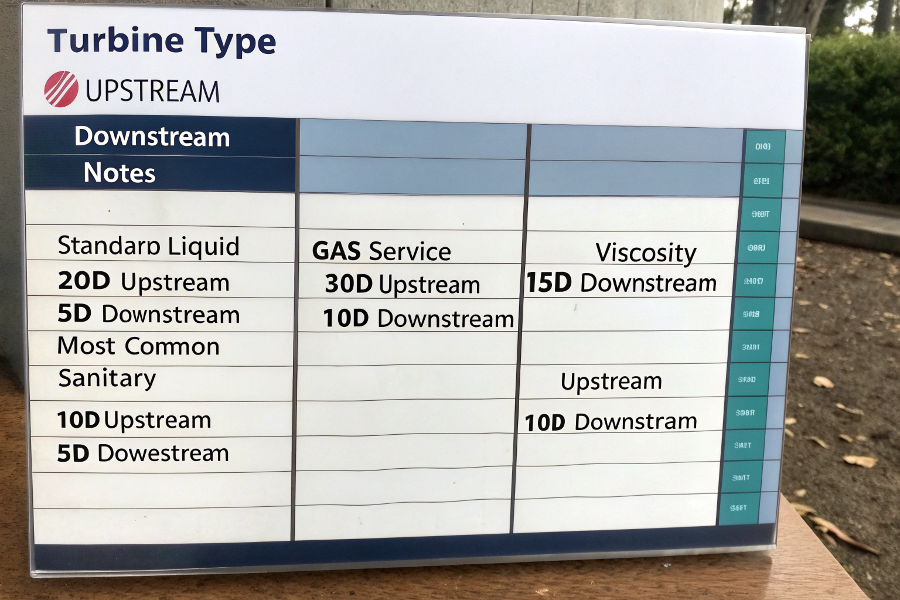

What Are the Upstream and Downstream Requirements for Turbine Meter?

Five turbine meter subtypes with varying needs:

| Straight-Run Comparison Chart | Turbine Type | Upstream | Downstream | Notes |

|---|---|---|---|---|

| Standard Liquid | 20D | 5D | Most common | |

| Gas Service | 30D | 10D | Density sensitive | |

| High Viscosity | 30D | 15D | Avoid laminar flow | |

| Sanitary | 10D | 5D | Tri-clamp fittings | |

| Cryogenic | 25D | 10D | Special bearings |

Maintenance Considerations

Bearing Wear

- Annual inspection

- Listen for noise

- Monitor K-factor

Flow Ranges

- Stay above 5:1 turndown

- Avoid low-flow conditions

- Watch for overspin

Filter Requirements

- 100 mesh standard

- Check monthly

- Differential pressure

Turbine Meter Internals

Installation Do’s and Don’ts

Do:

- Install upstream strainer

- Use proper supports

- Align carefully

- Ground properly

- Keep fluids clean

Don’t:

- Exceed rated velocity

- Allow two-phase flow

- Install near vibrations

- Skip calibration

- Ignore pressure drops

Conclusion

Vortex meters require 15D upstream and 5D downstream piping, with ultrasonic (10D/5D), magnetic (5D/3D), and turbine meters (20D/5D) having different needs. All flow measurement technologies depend on proper straight-run distances, but specific requirements vary by meter principle, fluid properties, and piping configuration. When space constraints prevent ideal installations, flow conditioners or alternative technologies may provide solutions while maintaining measurement accuracy. Following manufacturer specifications for each meter type ensures optimal performance and longevity.