Process engineers frequently overlook straight-run distances, not realizing these requirements can affect measurement accuracy by 5-10%. Small installation errors cause big operational problems.

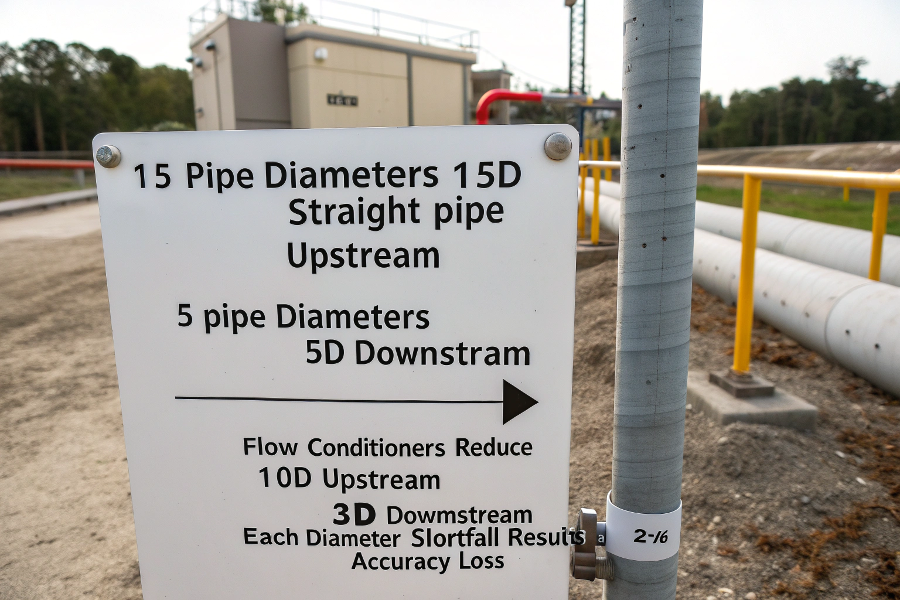

Vortex flow meters typically require 15 pipe diameters (15D) of straight pipe upstream and 5 diameters (5D) downstream for accurate measurement. These distances ensure fully developed flow profiles, with exceptions made when using flow conditioners (reducing requirements to 10D/3D) or facing space constraints (±2% accuracy loss per diameter shortfall).

Vortex Meter Straight-Run

Straight-run needs vary based on three core factors: meter type, upstream disturbances, and fluid properties. Below are the specific requirements for different flow meter technologies.

What Is the Straight Length Requirement for a Vortex Flowmeter?

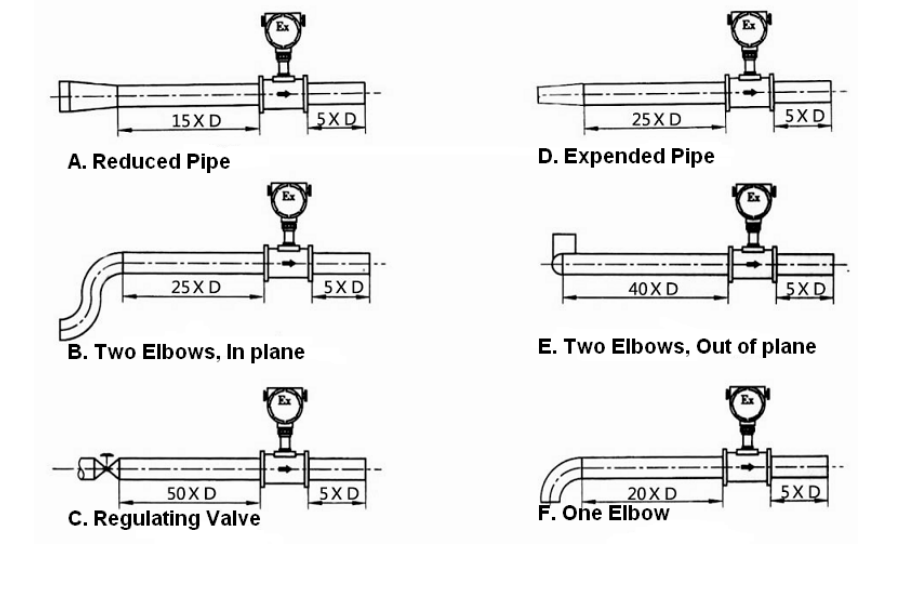

Four key installation scenarios for vortex meters:

Vortex Straight-Run Requirements Table

| Pipe Condition | Upstream Requirement | Downstream Requirement | Accuracy Impact |

|---|---|---|---|

| Clean pipe | 15D | 5D | ±1% |

| After 90° elbow | 25D | 10D | ±2.5% |

| After valve | 35D | 15D | ±5% |

| After pump | 50D | 20D | ±7.5% |

| With conditioner | 10D | 3D | ±1.5% |

Installation Best Practices

Measurement Impact

- 15D upstream = Factory-specified accuracy

- 10D upstream = 1.5% accuracy degradation

- 5D upstream = 5% accuracy degradation

Flow Conditioning Options

- Perforated plates (40% reduction)

- Tube bundles (50% reduction)

- Honeycomb screens (60% reduction)

Special Cases

- Wet gas streams (+10D)

- High viscosity liquids (+5D)

- Pulsating flows (+15D)

Vortex Meter Installation

How to Calculate Straight-Run Distances

- For 6" (150mm) pipe:

- 15D upstream = 15 × 6" = 7.5 ft (2.29m)

- 5D downstream = 5 × 6" = 2.5 ft (0.76m)

- For 4" (100mm) pipe:

- 15D upstream = 15 × 4" = 5 ft (1.52m)

- 5D downstream = 5 × 4" = 20" (0.51m)

What Is the Straight Run Requirement for Flow Meters?

Five major flow meter types compared:

Flow Meter Straight-Run Comparison

| Meter Type | Upstream | Downstream | Notes |

|---|---|---|---|

| Vortex | 15D | 5D | Most common |

| Magnetic | 5D | 3D | Least demanding |

| Turbine | 20D | 5D | Bearing sensitive |

| Ultrasonic | 10D-15D | 5D | Profile-dependent |

| Orifice | 20D-40D | 5D | Highest requirements |

General Installation Rules

Upstream Considerations

- Pumps require maximum distance

- Valves need intermediate space

- Elbows create swirl patterns

Downstream Needs

- Mostly for flow redevelopment

- Less critical than upstream

- Still impacts K-factor

Common Mistakes

- Ignoring reducer effects

- Underestimating valve impact

- Not accounting for tee connections

%(percentage)comparison chart

Straight-Run Comparison

When Standard Distances Aren’t Possible

- Alternative Solutions:

- Install flow conditioners

- Relocate measurement point

- Use different meter type

- Accept accuracy reduction

- Add calibration factor

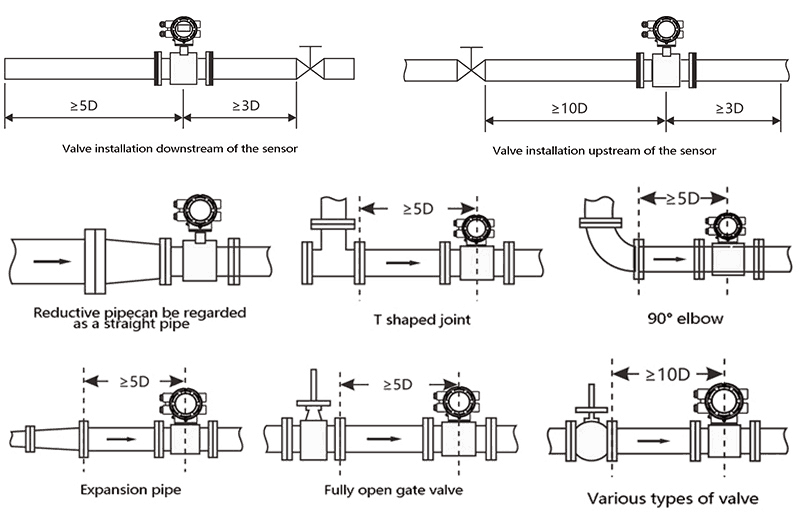

What Are the Requirements for a Magnetic Flow Meter Straight Run?

Three magmeter installation scenarios:

Magnetic Flow Meter Requirements

| Installation Type | Upstream | Downstream | Key Points |

|---|---|---|---|

| Full-bore | 5D | 3D | Most tolerant |

| Insertion | 10D | 5D | Profile sensitive |

| Low-flow | 8D | 5D | Laminar concerns |

Critical Installation Factors

Pipe Lining Impact

- Rubber-lined: Standard distances

- PTFE-lined: +2D upstream

- Ceramic-lined: Normal rules

Electrode Orientation

- Horizontal preferred

- 45° acceptable

- Vertical possible

Grounding Needs

- Must ground properly

- Ground rings if needed

- Verify connection

Magmeter Installation

When to Break the Rules

- Acceptable Exceptions:

- Custody transfer: Never

- Process control: 20% reduction

- Monitoring only: 50% reduction

- With conditioners: 50% reduction

- Calibrated field: 30% reduction

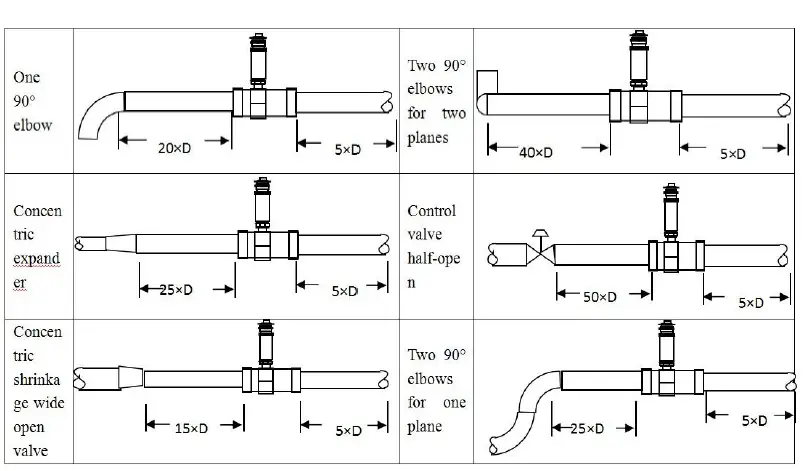

What Is the Straight Length Requirement for Turbine Flow Meter?

Five turbine meter categories:

Turbine Meter Straight-Run Guide

| Turbine Type | Upstream | Downstream | Special Notes |

|---|---|---|---|

| Standard liquid | 20D | 5D | Most common |

| Gas service | 25D | 10D | Density sensitive |

| High viscosity | 30D | 10D | Avoid laminar flow |

| Sanitary | 15D | 5D | Tri-clamp fittings |

| Cryogenic | 20D | 10D | Special bearings |

Installation Critical Points

Bearing Protection

- Proper filtration required

- Minimum 100 mesh

- Regular maintenance

Flow Conditioning

- Straightening vanes help

- Conditioner options limited

- May void warranty

Velocity Profile

- Laminar flow damages

- Pulsation harms bearings

- Stratification affects K-factor

Turbine Meter Piping

Industry-Specific Requirements

- Oil & Gas: +5D for safety

- Chemical Processing: Special materials

- Water Treatment: Standard distances

- Pharmaceutical: Sanitary designs

- Food & Beverage: CIP considerations

Conclusion

Vortex flow meters demand 15D upstream/5D downstream straight pipes, while magmeters need only 5D/3D and turbine meters require 20D/5D. All flow measurement technologies require undisturbed flow profiles, but necessary distances vary significantly by meter principle and installation conditions. When space constraints prevent ideal installations, flow conditioners, meter relocation, or alternative