Choosing the wrong type of ultrasonic flow meter can result in wasted investment and unreliable measurements in your liquid applications.

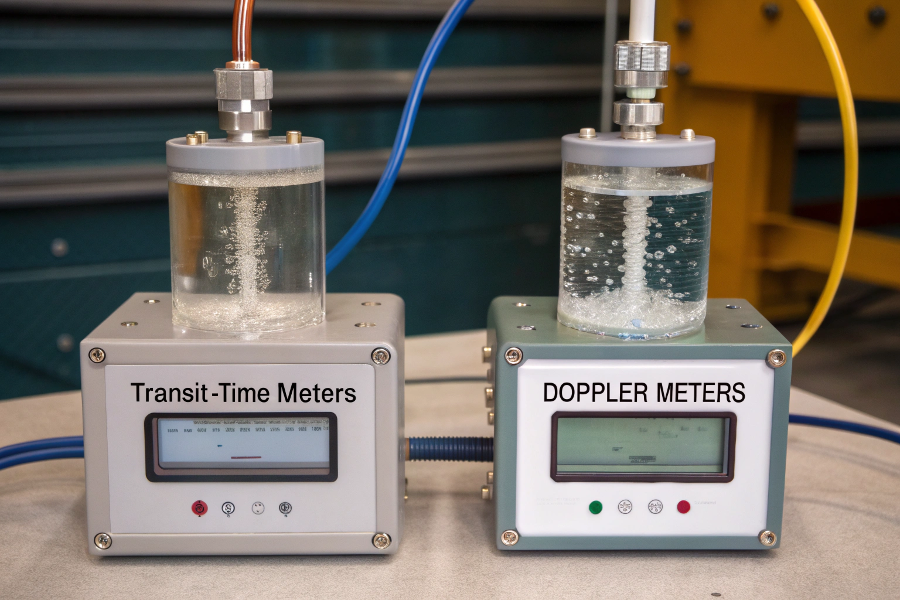

Ultrasonic flow meters for liquids come in two main types: transit-time and Doppler, each designed for specific fluid conditions and measurement requirements.

Types of Ultrasonic Flow Meters

Let me share my expertise to help you make the right choice for your liquid flow measurement needs.

What Are the Two Types of Ultrasonic Flow Meters?

Selecting between transit-time and Doppler technology is crucial for accurate measurements.

The two types are transit-time meters, which measure clean liquids using time difference, and Doppler meters, which use frequency shift in particle-containing fluids.

Transit-Time vs Doppler Technology

From my extensive field experience:

Transit-Time Technology

-

Operating Principles

Feature Description Application Signal Path Diagonal crossing Clean liquids Measurement Time difference High accuracy Installation External/Internal Non-intrusive Accuracy Up to ±0.5% Precise control -

Key Requirements

- Clean fluid

- Minimal bubbles

- Good pipe condition

- Stable flow

Doppler Technology

-

Operating Characteristics

Feature Description Application Signal Path Single-sided Dirty liquids Measurement Frequency shift Particle content Installation External Simple setup Accuracy 1-2% typical Process monitoring -

Application Needs

- Suspended particles

- Minimum particle size

- Adequate concentration

- Reflective particles

What Ultrasonic Flow Meter is Best for Fluid with Slurries, Liquids with Bubbles, and Gases?

Many engineers struggle with measuring challenging fluids accurately.

Doppler ultrasonic flow meters are best for slurries and liquids with bubbles, while specialized transit-time meters are designed for gas applications.

Flow Measurement in Challenging Fluids

Based on my implementation experience:

Fluid Type Considerations

-

Slurry Applications

Parameter Requirement Impact Particle Size >100 microns Signal strength Concentration >100 ppm Reflection quality Flow Speed >1 ft/s Measurement stability Pipe Loading Consider wear Maintenance -

Special Conditions

- Bubble content

- Flow regime

- Temperature effects

- Pressure conditions

Selection Guidelines

-

Application Matching

- Fluid properties

- Process conditions

- Accuracy needs

- Installation constraints

-

Performance Factors

- Signal quality

- Measurement stability

- Maintenance requirements

- Cost considerations

What is the Instrument Used to Measure the Flow of Liquids?

Choosing the right flow measurement technology can be overwhelming with so many options available.

Various instruments measure liquid flow, including ultrasonic, magnetic, Coriolis, vortex, and differential pressure meters, each suited for specific applications.

Liquid Flow Measurement Instruments

Drawing from my technical knowledge:

Common Flow Technologies

-

Technology Comparison

Type Principle Best For Limitations Ultrasonic Sound waves Clean/dirty liquids Installation critical Magnetic Conductivity Conductive fluids Limited to conductives Coriolis Mass flow High accuracy High cost Vortex Shedding Simple operation Min flow required -

Selection Criteria

- Fluid properties

- Accuracy needs

- Budget constraints

- Installation requirements

Application Considerations

-

Process Factors

- Flow range

- Pressure limits

- Temperature range

- Fluid compatibility

-

Operational Needs

- Maintenance access

- Calibration requirements

- Power availability

- Output signals

What Are the Disadvantages of an Ultrasonic Flow Meter?

Understanding limitations helps prevent application mistakes and disappointment.

Main disadvantages include sensitivity to installation conditions, flow profile requirements, and limitations with certain fluid properties.

Ultrasonic Flow Meter Limitations

From my troubleshooting experience:

Key Limitations

-

Installation Challenges

Challenge Impact Solution Straight Run Flow profile Proper planning Pipe condition Signal quality Surface prep Access space Maintenance Design layout Mounting Stability Proper support -

Technical Constraints

- Flow profile sensitivity

- Temperature effects

- Signal interference

- Fluid requirements

Mitigation Strategies

-

Design Considerations

- Proper location selection

- Installation method

- Environmental protection

- Maintenance access

-

Operational Solutions

- Regular calibration

- Signal monitoring

- Preventive maintenance

- Staff training

Conclusion

Understanding ultrasonic flow meter types, applications, and limitations is essential for successful implementation in liquid flow measurement applications, ensuring reliable and accurate results.