Confusion about ultrasonic flow meter diagrams often leads to installation errors and poor measurement performance, causing significant process control problems.

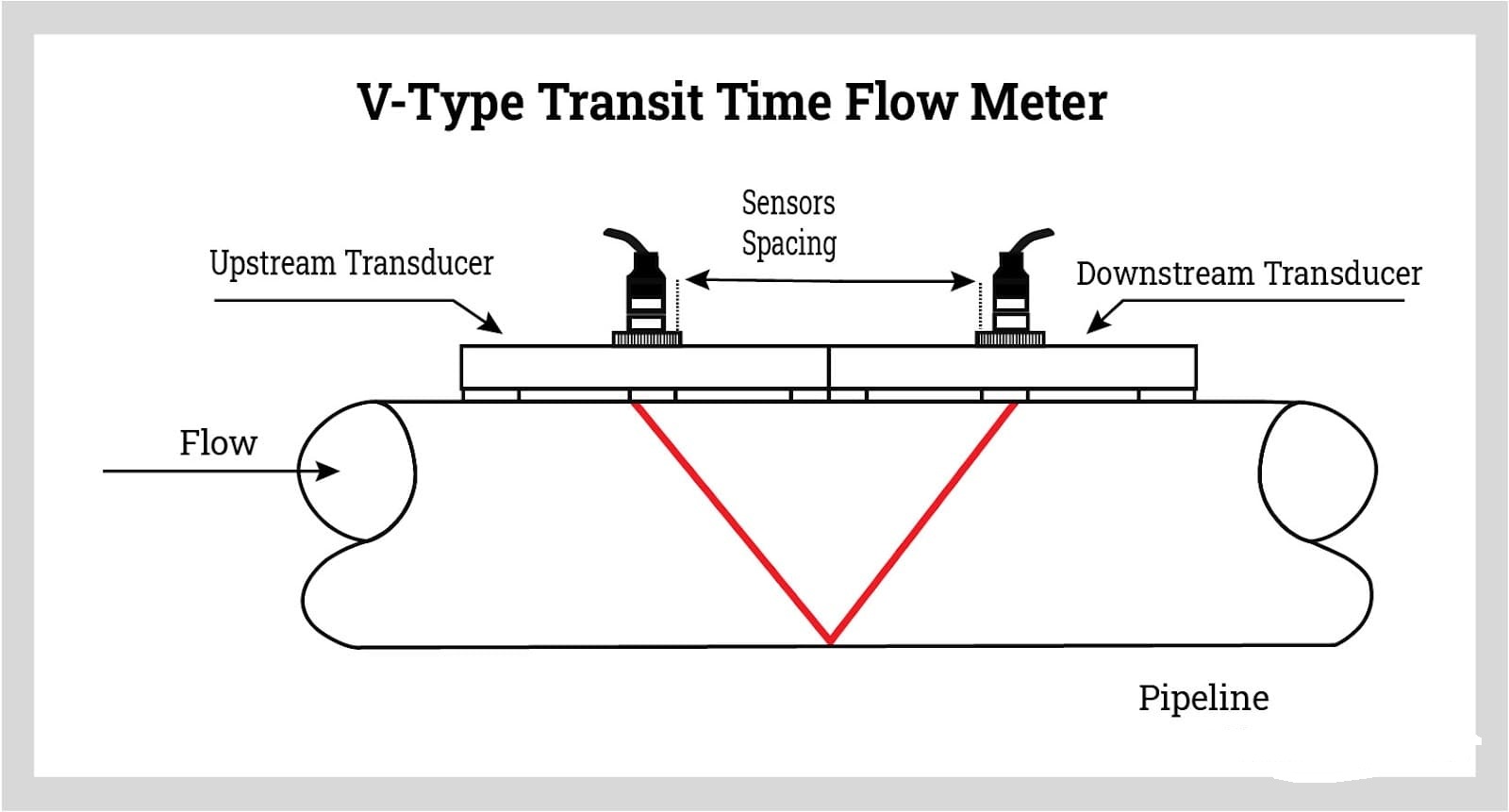

An ultrasonic flow meter diagram shows transducer placement, sound wave paths, and measurement principles, with typical configurations including single, dual, or multi-path arrangements.

Basic Ultrasonic Flow Meter Configuration

I’ve helped many customers understand these diagrams, and I’ll share key insights to ensure proper installation and operation.

How Does the Ultrasonic Flow Meter Work?

Misunderstanding the working principle leads to incorrect installation and unreliable measurements.

Ultrasonic flow meters work by measuring the time difference between upstream and downstream sound waves traveling through the fluid, using this to calculate flow velocity.

Ultrasonic Flow Meter Working Principle

From my technical experience:

Operating Principles

-

Measurement Methods

Method Description Application Transit Time Time Difference Clean Liquids Doppler Frequency Shift Dirty Fluids Hybrid Combined Systems Mixed Services Cross-Correlation Pattern Analysis Complex Flows -

Signal Path Types

- Direct path

- Reflected path

- Multiple bounce

- Crossed paths

Signal Processing

-

Key Components

- Transducer pairs

- Processing unit

- Temperature sensors

- Signal amplifiers

-

Calculation Elements

- Transit time differences

- Flow velocity profiles

- Temperature compensation

- Reynolds number corrections

How to Measure Ultrasonic Flow Meter?

Incorrect measurement setup can result in significant accuracy losses and system failures.

Proper measurement requires precise transducer positioning, accurate pipe parameter entry, and careful attention to installation conditions.

Measurement Setup Configuration

Based on my installation experience:

Installation Requirements

-

Critical Parameters

Parameter Measurement Tool Importance Pipe OD Caliper/Tape Critical Wall Thickness Thickness Gauge Essential Mounting Distance Spacing Tool Critical Alignment Level Indicator Important -

Setup Procedures

- Surface preparation

- Transducer mounting

- Cable routing

- Signal verification

Verification Process

-

System Checks

- Signal strength

- Zero flow testing

- Range validation

- Repeatability assessment

-

Documentation Requirements

- Installation photos

- Parameter records

- Calibration data

- Performance logs

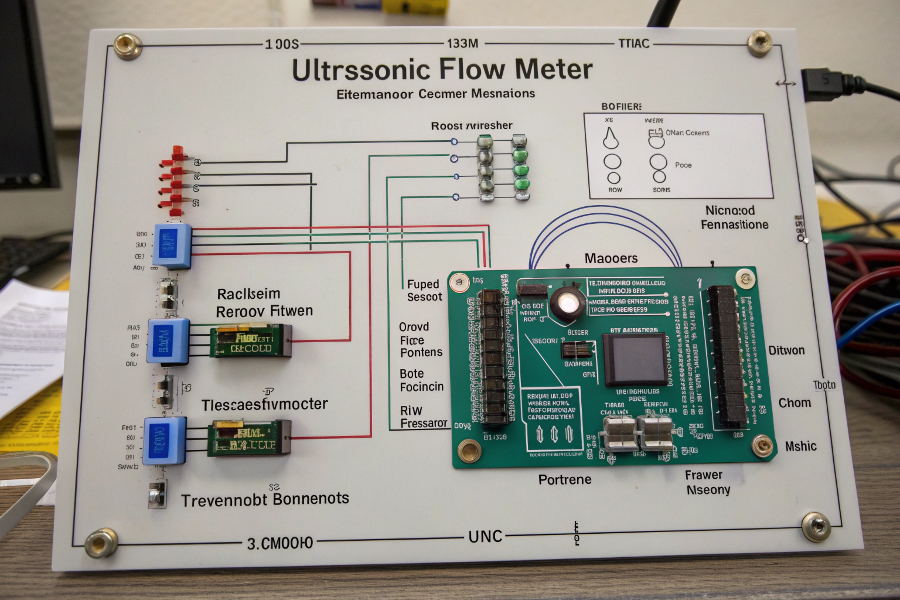

How to Make an Ultrasonic Flow Meter?

Building without proper understanding of component relationships can lead to measurement failures.

Creating an ultrasonic flow meter requires careful integration of transducers, electronics, and software following specific circuit and component diagrams.

Flow Meter Component Layout

Drawing from my manufacturing knowledge:

Component Layout

-

Essential Elements

Component Function Connection Type Transducers Signal Generation Coaxial Circuit Board Processing Multi-layer Display Interface Digital Power Supply Energy Source Regulated -

Circuit Requirements

- Signal amplification

- Noise filtering

- Temperature compensation

- Communication interfaces

Assembly Guidelines

-

Construction Steps

- PCB assembly

- Housing preparation

- Component mounting

- Quality testing

-

Testing Procedures

- Functional verification

- Accuracy testing

- Environmental testing

- Safety certification

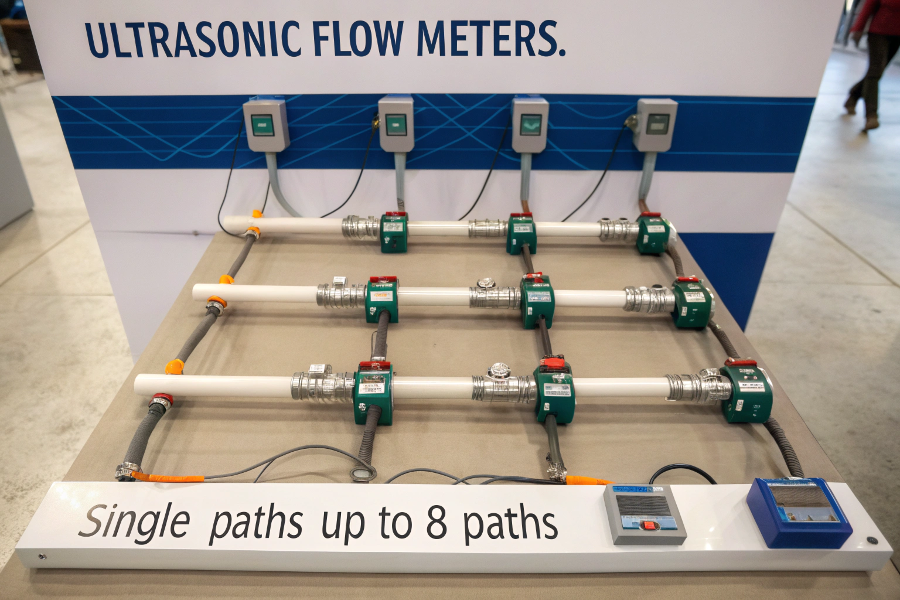

How Many Paths Does an Ultrasonic Flow Meter Have?

Not understanding path configurations can result in selecting the wrong meter for your application.

Ultrasonic flow meters can have single, dual, or multiple paths, typically ranging from 1 to 8 paths, with more paths providing higher accuracy.

Flow Meter Path Configurations

From my design experience:

Path Configurations

-

Common Arrangements

Path Count Accuracy Application Single ±1-2% Basic Monitoring Dual ±0.5-1% Process Control Four ±0.3-0.5% Custody Transfer Eight ±0.1-0.3% High Precision -

Selection Factors

- Required accuracy

- Flow profile complexity

- Installation constraints

- Budget considerations

Implementation Details

-

Design Considerations

- Path placement

- Transducer spacing

- Signal integration

- Processing requirements

-

Performance Factors

- Flow profile effects

- Installation impacts

- Maintenance needs

- Calibration requirements

Conclusion

Understanding ultrasonic flow meter diagrams is crucial for proper installation, operation, and maintenance, ensuring accurate flow measurement and reliable system performance.