Ultrasonic Level Meter

An Ultrasonic Level Meter is a non-contact device that measures liquid or solid levels using ultrasonic sound waves. It emits high-frequency sound pulses toward the surface, calculates the time for the echo to return, and determines the level based on the speed of sound. Suitable for various industries, it’s ideal for wastewater, chemical tanks, and silos. It offers accurate, reliable, and maintenance-free measurements for continuous level monitoring in challenging environments.

Integrated Type

ultrasonic level meter

remote Type

ultrasonic level meter

Explosion-proof type

ultrasonic level meter

Dual-chamber

ultrasonic level meter

All You Need to know About Ultrasonic level meter

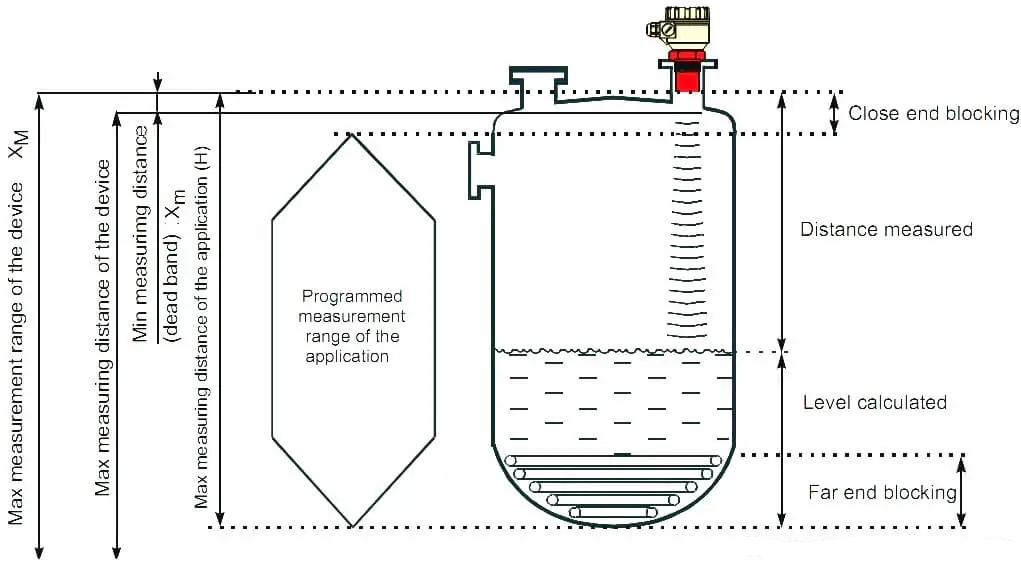

Ultrasonic level Meter Principle

An Ulritrasound Level Meter works by emitting high-frequency sound waves from a transducer toward the surface of the liquid or solid material being measured. The sound waves travel through the air, hit the surface, and reflect back as an echo to the transducer. The device calculates the time difference between the emission and reception of the sound waves. Using the speed of sound in the medium (usually air), it determines the distance to the surface. The level is then derived by subtracting this distance from the total height of the tank or container, providing an accurate and non-contact measurement of the material level.

Advantages of Ultrasonic level Meter

Non-Contact Measurement

Works without touching the material, ideal for corrosive, hazardous, or sensitive substances.

Versatility

Suitable for liquids, solids, and slurries in various industries like water treatment, chemical, and food processing.

High Accuracy

Provides precise and reliable level measurements.

Wide Application

Can measure levels in large or deep tanks and containers.

ultrasonic level meter application

Ultrasonic Level Meters are widely used across various industries due to their versatility and non-contact measurement capabilities. Here are some key applications:

Water and Wastewater Treatment

Chemical and Petrochemical Industry

Food and Beverage Industry

Pharmaceutical Industry

Oil and Gas Industry

Agriculture

Manufacturing and Process Industries

Mining and Minerals

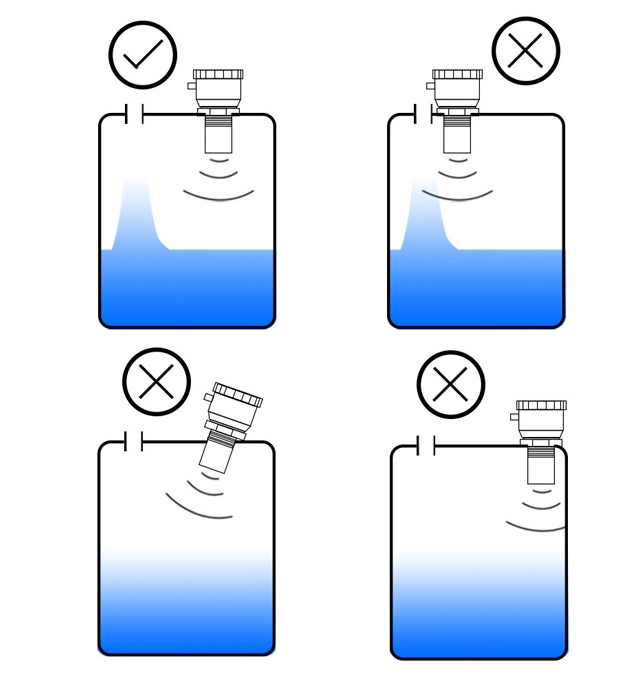

Installation Requirement

To install an ultrasonic level meter, select a location free from obstructions and turbulence. Mount the sensor securely using a bracket or flange, ensuring it is perpendicular to the material surface. Avoid vibrations and ensure proper environmental conditions (temperature, pressure, dust). Connect wiring according to the manufacturer’s diagram, ground the system, and provide the correct power supply. Configure the device by setting parameters like tank height and measurement range, and perform zero calibration. Test functionality by measuring the empty level and verifying signal strength. Regularly check alignment and clean the sensor for optimal performance. This ensures accurate, reliable level measurements.

Production Process