Incorrect straight run lengths can impact turbine flow meter readings drastically and affect operational accuracy.

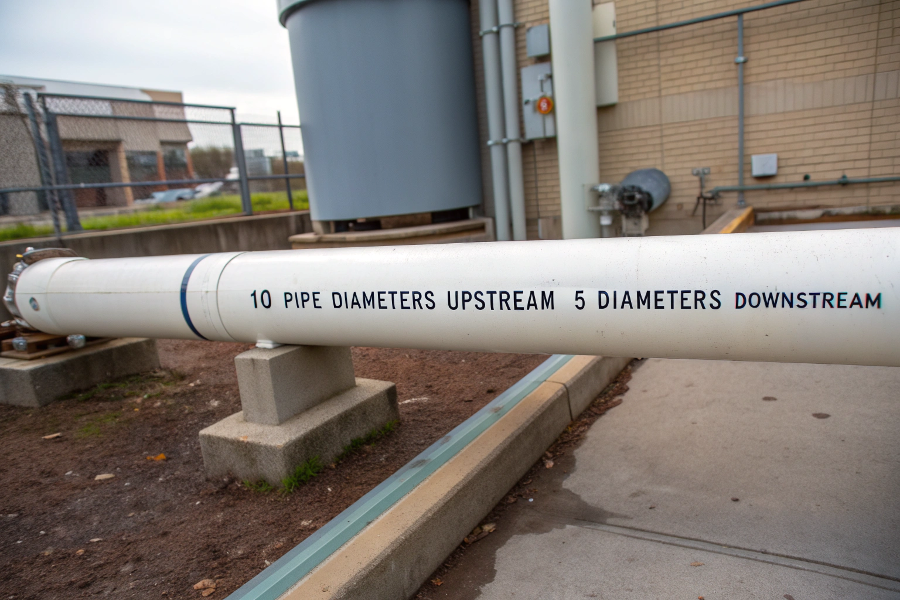

The standard straight run requirement for a turbine flow meter is 10 pipe diameters upstream and 5 diameters downstream. This ensures the flow profile is fully developed, minimizing measurement errors.

Straight Run Requirement for Turbine

Following these guidelines helps achieve accurate flow measurements and enhances meter performance.

What Is the Straight Length Requirement for Turbine Flow Meter?

Finding the right straight length is crucial to measurement accuracy.

For turbine flow meters, a straight length of 10 pipe diameters upstream and 5 diameters downstream is required. This helps prevent disturbances from fittings, ensuring a stable and consistent flow for accurate readings.

%(percentage)pipe-length-guide

Length Specifications

Understanding these requirements allows for better planning during meter installation, enhancing data reliability.

What Is the Straight Run Requirement for Flow Meters?

Different flow meters have variable straight run needs for precise operation.

Flow meters typically require a straight run of 5 to 10 pipe diameters upstream and 5 downstream. These values vary with the meter type and specific application to stabilize the flow profile for error reduction.

General Flow Meter Run

Consulting the manufacturer’s guidelines ensures compliance with specific meter installations and optimal performance.

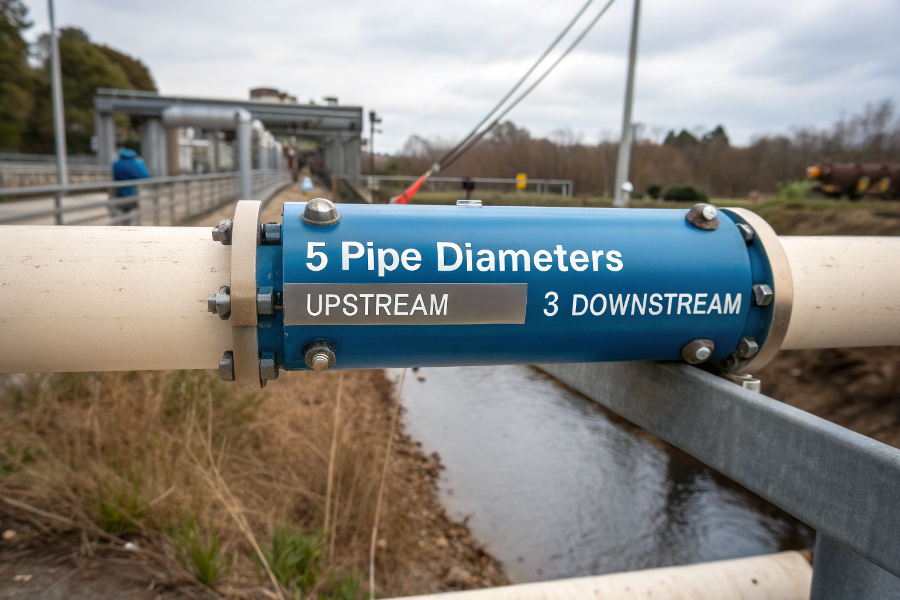

What Are the Requirements for a Magnetic Flow Meter Straight Run?

Magnetic flow meters have distinct straight run specifications for desired accuracy.

Magnetic flow meters usually need a straight length of 5 pipe diameters upstream and 3 downstream. These specifications preserve flow stability, minimizing effects from upstream disturbances for better accuracy.

Magnetic Meter Length

Adhering to these metrics ensures magnetic flow meters operate effectively and deliver precise readings.

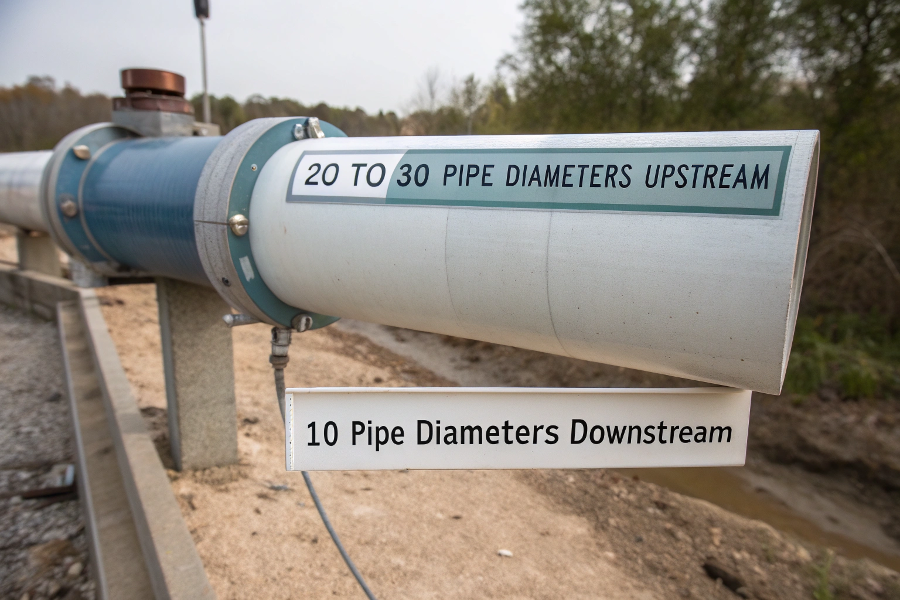

What Is the Straight Length Requirement for a Vortex Flow Meter?

Vortex flow meters require specific straight run conditions to function well.

Vortex flow meters generally require 20 to 30 pipe diameters of straight run upstream and 10 downstream. Such extensive lengths accommodate the sensitivities involved in vortex formation and capture clean flow conditions.

Vortex Flow Meter Length

Understanding these requirements fosters proper planning and enhances the operational efficiency of vortex meters.

Conclusion

Turbine flow meters require a straight run of 10 pipe diameters upstream and 5 downstream. Similar guidelines apply to other meters, ensuring flow stability and precise measurements.