Turbine Flow Meter

A turbine flow meter is a new generation kind of flow meter that absorbs the advanced technologies of flow meter at home and abroad. It has been optimized and designed to have so many characteristics, such as simple structure, light weight, high precision, good repeatability,easy installation and usage.

Flange Type

Liquid Turbine Flow Meter

Thread Type

Liquid Turbine Flow Meter

Tri-Clamp Type

Liquid Turbine Flow Meter

Flange Type

Gas Turbine Flow Meter

All You Need to know About Turbine Flow Meter

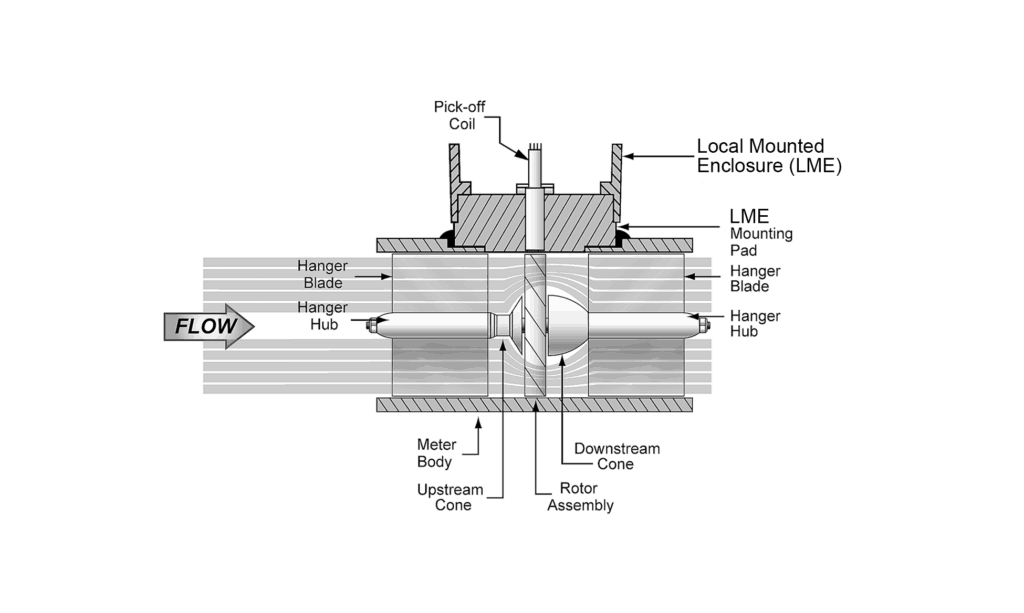

Turbine Flow Meter Principle

The turbine flow meter works by using the flow of fluid to spin a turbine wheel inside the meter. As the fluid passes through, it turns the turbine, and the speed of rotation is proportional to the flow rate. A sensor detects the turbine’s rotations, converting them into electrical pulses. These pulses are then used to calculate the flow rate and total volume of the fluid. This principle provides accurate and reliable measurements for clean, low-viscosity liquids and gases.

Advantages of Turbine Flow Meter

Compact Design

Their relatively small and lightweight construction makes them easy to install.

High Accuracy

They provide precise measurements, especially for clean and low-viscosity fluids.

Quick Response

They respond rapidly to changes in flow rates, making them suitable for dynamic systems.

Wide Application

Capable of measuring a broad range of flow rates with consistent accuracy.

Turbine Flow Meter Application

- Oil and Gas: Measuring the flow of crude oil, refined products, and natural gas in pipelines, refineries, and distribution systems.

- Water and Wastewater: Monitoring clean water, treated water, and effluent flows in treatment plants and distribution networks.

- Chemical and Petrochemical: Accurately measuring the flow of chemicals, solvents, and other process fluids in manufacturing and processing plants.

- Food and Beverage: Ensuring precise measurement of liquids like milk, juice, and syrup in production and packaging processes.

- Pharmaceutical: Monitoring the flow of purified water, solvents, and other fluids in drug manufacturing.

- Aerospace: Measuring fuel flow in aircraft and spacecraft systems.

- HVAC: Monitoring the flow of water or refrigerants in heating, cooling, and ventilation systems.

- Power Generation: Measuring feedwater, condensate, and fuel oils in power plants.

Installation Requirement

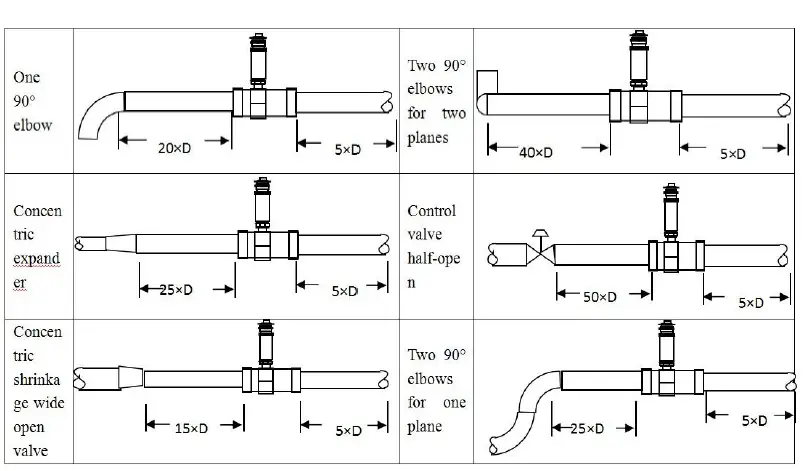

When installing a turbine flow meter, ensure adequate straight pipe sections (10-15 times pipe diameter upstream and 5 times downstream), avoid placing near valves or bends, and align with the flow direction arrow. Clean pipes thoroughly to prevent damage to the turbine blades, and ensure proper grounding and signal line connections are securely established. After installation, conduct a system test to verify proper operation. Position the meter in a location that allows easy access for future maintenance. Following these steps ensures accurate flow measurement, protects the meter from damage, and simplifies troubleshooting and upkeep. Always refer to the manufacturer’s guidelines for specific requirements.

Production Process